Laser sensor-based welding seam automatic tracking test device and test method thereof

A laser sensor, testing device technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems that have not been seen before.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

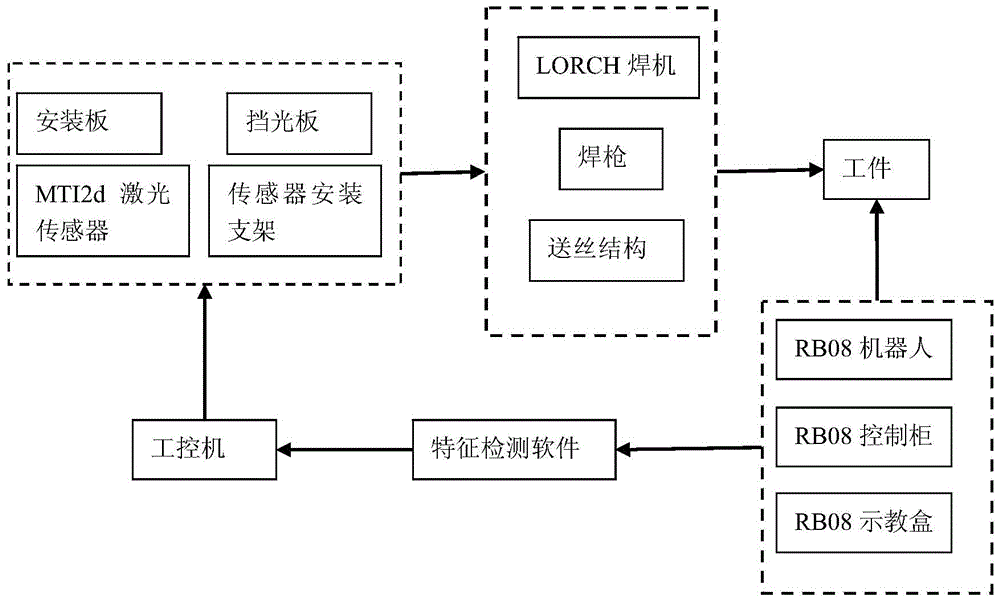

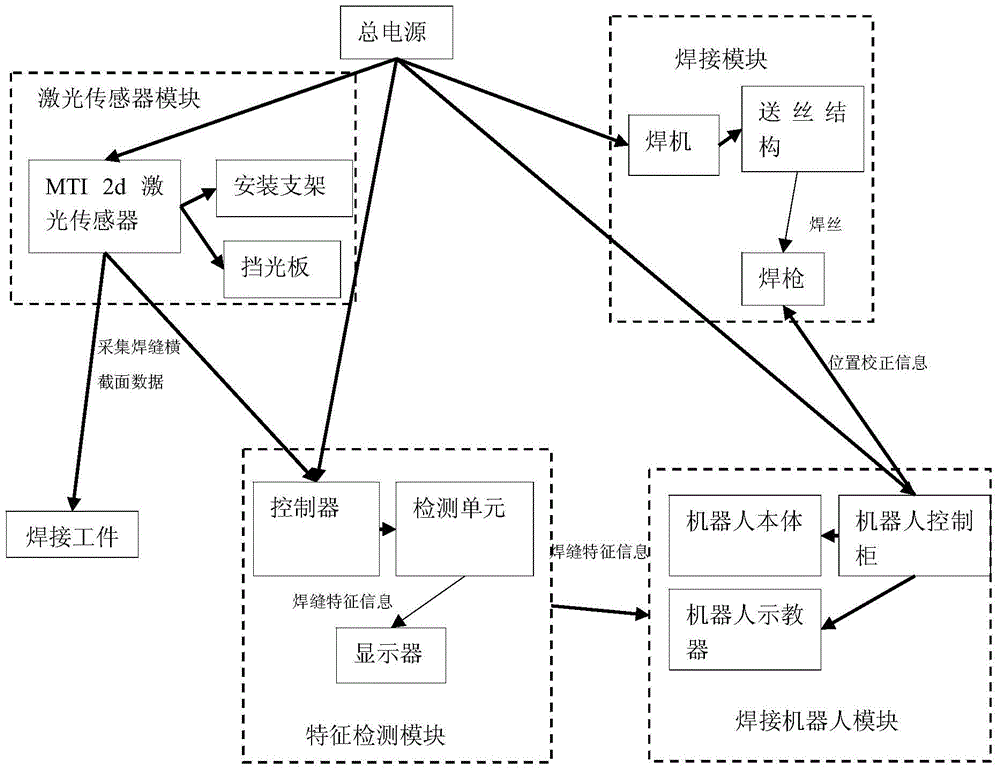

[0084] Such as figure 1 As shown, a laser sensor-based welding seam automatic tracking test device includes: a welding robot module, a laser sensor module, a welding module and a feature detection module.

[0085] Such as figure 2 As shown, the laser sensor module: MTI 2d stripe laser sensor, sensor mounting bracket, light baffle, and mounting plate together constitute the entire sensor module, which is connected to the end flange of the robot through the sensor mounting bracket.

[0086] Welding module: LORCH welding machine, wire feeding structure and welding torch form the whole welding module, which controls the arc starting and feeding of welding wire.

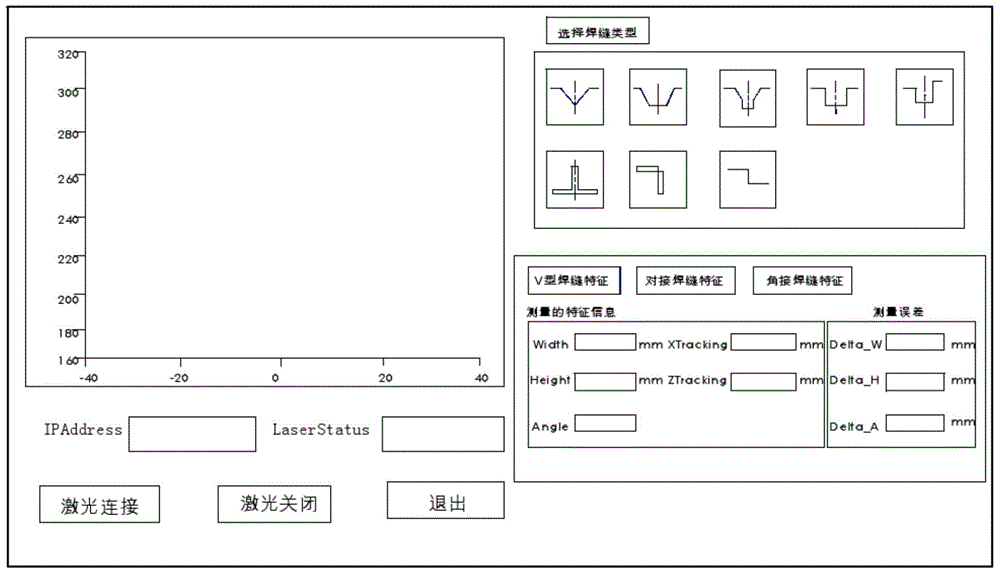

[0087] Feature detection module: Industrial computer and welding control software together constitute the control module of the whole system. The weld feature point detection algorithm of the control software uses wavelet transform and least square method to process data, extract the feature points of the weld and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com