Metal cutting machine slag-splashing protection and collection device

A collection device and cutting machine technology, applied in metal processing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of metal sparks splashing, polluting the air environment, occupational disease injuries, etc., to facilitate on-site construction, the effect Good, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

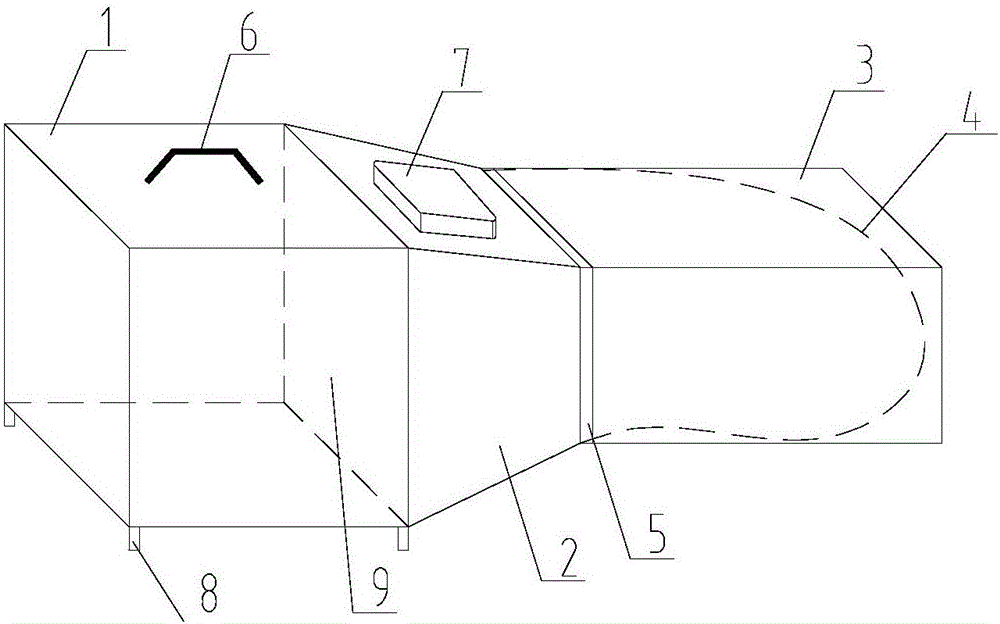

[0013] This embodiment provides a metal cutting machine slag protection and collection device, the structure is as follows figure 1 As shown, it includes the inlet port of the suction splash, the working end of the variable-section fan, and the protection and collection end of the splash; A handle 6 is installed on the top of the windshield, and a rubber elastic base 8 is provided at the bottom; one end of the inlet of the air suction spatter is connected to the slag outlet of the cutting machine, and the other end is connected to the large section end of the working end of the variable section fan. A steel wire filter screen 9 is provided at the connection between the splash inlet end and the working end of the variable cross-section fan. The working end of the variable cross-section fan is mainly composed of a variable cross-section metal frame 2 with openings at both ends and an axial flow fan 7 arranged in the variable cross-section metal frame. The small cross-section end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com