Movable one-time forming mould pressing plate forging process and mould

A mobile, mold technology, applied in the field of molded sheet manufacturing, can solve the problems of inability to achieve mass production, unstable product quality, and the opening of the file can not be too large, to achieve stable product quality, high uniformity, and improve product quality and output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

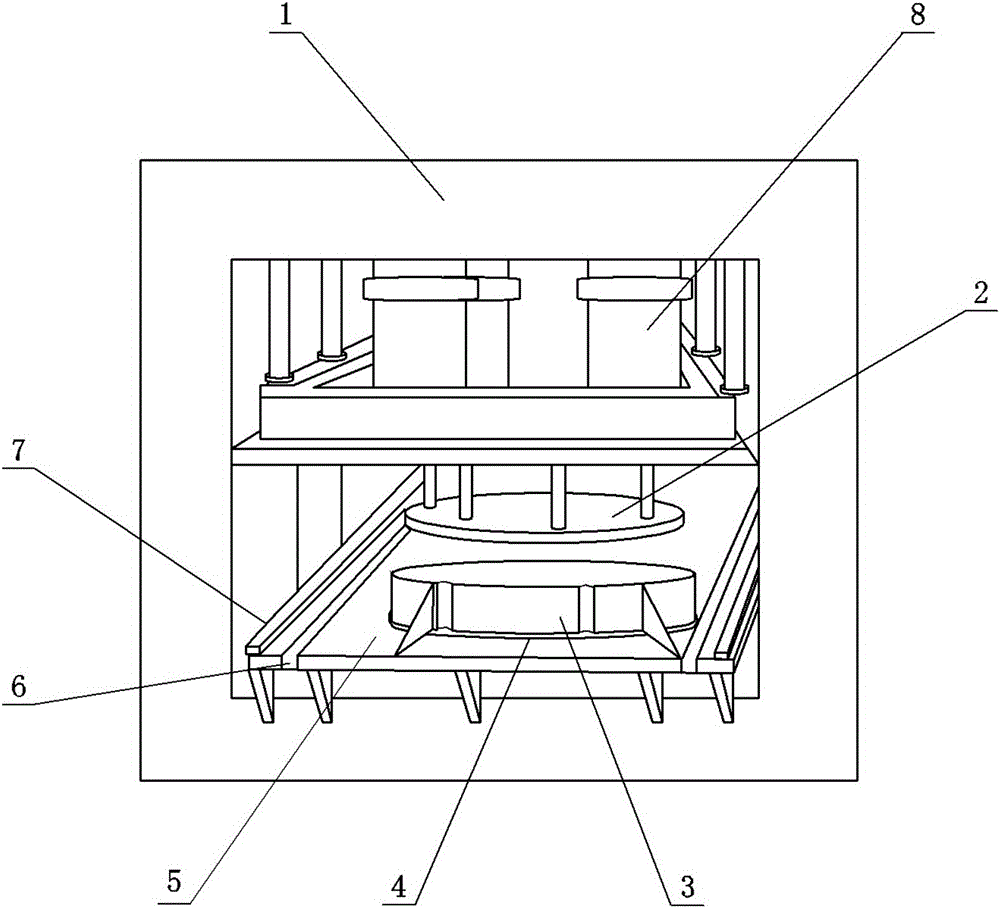

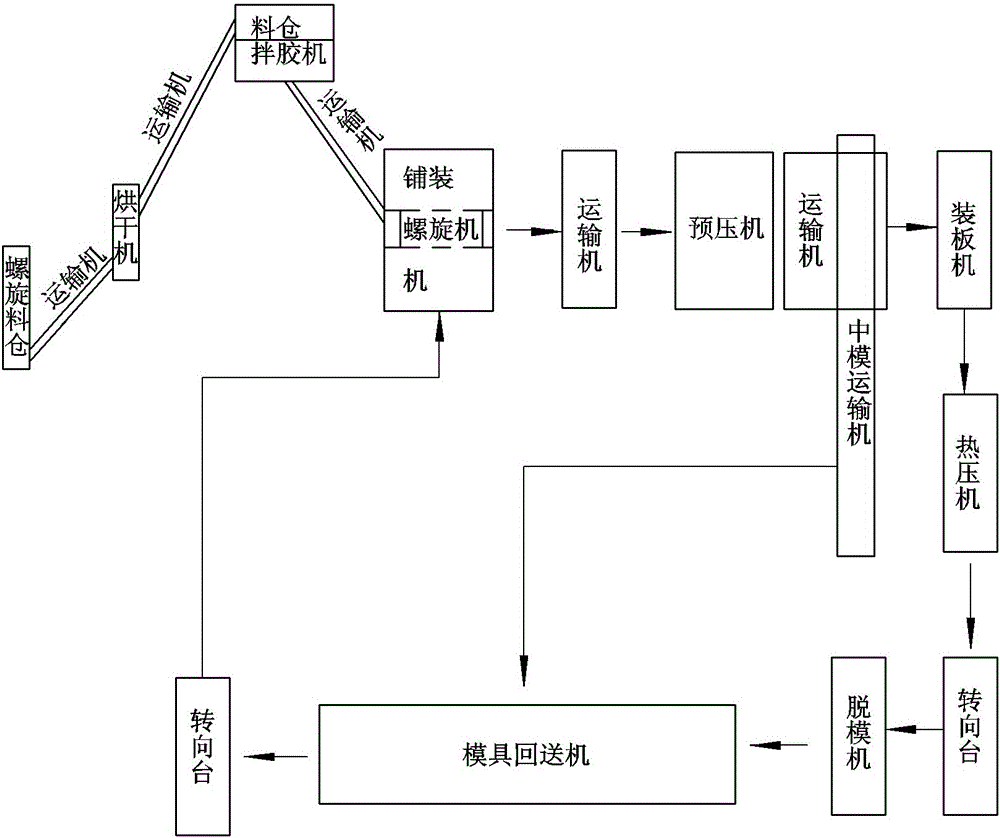

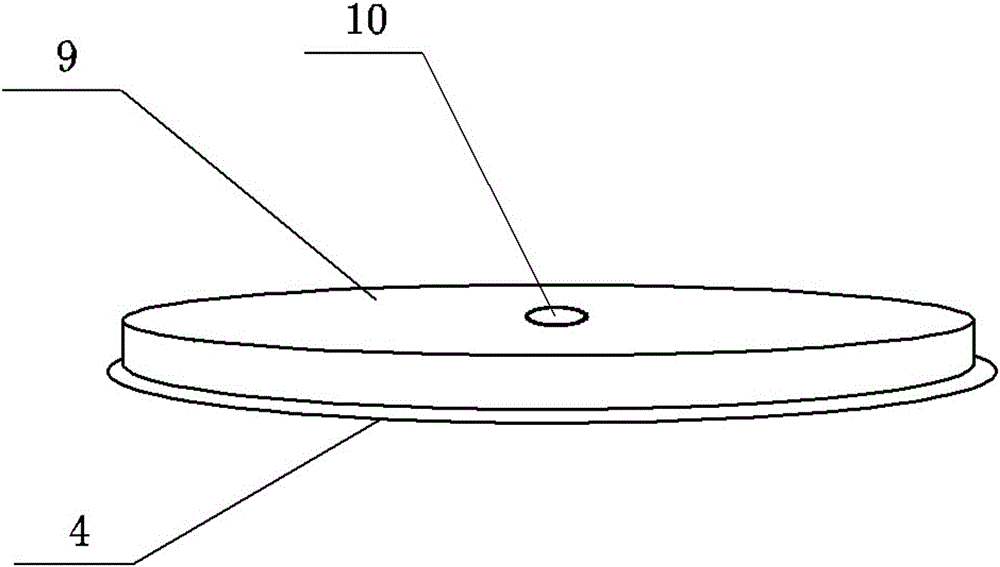

[0021] Embodiment 1: A kind of movable one-time forming molded plate making mold, see figure 2 , including silo glue mixing machine, pre-pressing machine, paving machine, conveyor, middle mold conveyor, board loading machine, hot press, demoulding machine, mold return machine and turning table, one end of the paving machine passes through the conveyor and The silo is connected to the outlet of the rubber mixing machine, and the same end is connected to the steering table where the middle mold and the bottom mold are placed. The other end of the paving machine is connected to the input end of the pre-press machine through the conveyor, and the output end of the pre-press machine is connected to another conveyor. , connect a medium mold conveyor to another conveyor, the output end of the medium mold conveyor is connected to the mold return machine, the other end of the conveyor is connected to the inlet of the loading machine, the outlet of the loading machine is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com