A suspending agent for electric porcelain glaze

A suspending agent and glaze technology, applied in the field of suspending agent, can solve problems such as stratification and precipitation, glaze layer quality problems, etc., and achieve the effects of improving stability, improving effect, improving efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

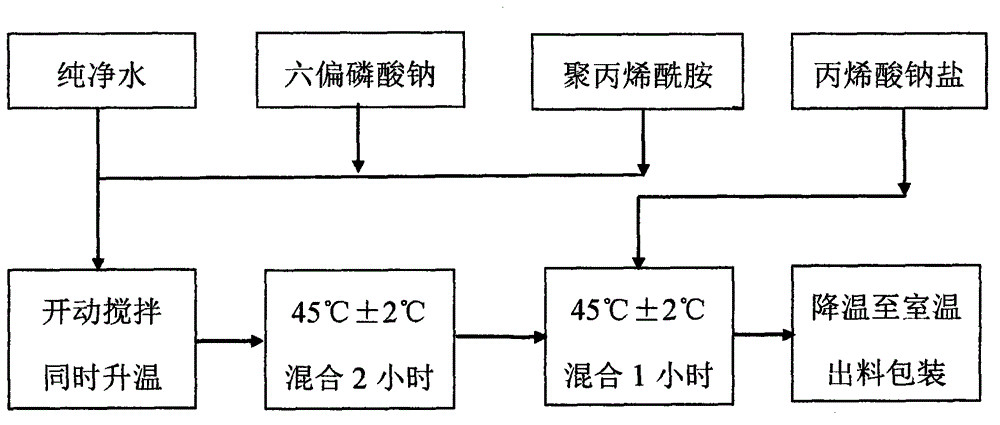

[0009] Example 1: Taking the preparation of 100kg suspension agent as an example, weigh 1kg industrial grade sodium hexametaphosphate, industrial grade polyacrylamide 0.5kg, industrial grade sodium acrylate 1kg, purified water 97.5kg, first put purified water and hexametaphosphate Put sodium phosphate and polyacrylamide into the electric heating reactor, start stirring and heat up to 45℃±2℃, mix and react for 2 hours, then put in sodium acrylate, continue to keep the temperature and stir for 1 hour, after cooling to room temperature, it will be discharged and packaged. It is a suspension product.

Embodiment 2

[0010] Example 2: Taking the preparation and synthesis of 100kg suspension agent as an example, weigh 2kg industrial grade sodium hexametaphosphate, industrial grade polyacrylamide 1kg, industrial grade sodium acrylate 1.5kg, purified water 95.5kg, first put purified water and hexametaphosphate Put sodium phosphate and polyacrylamide into the electric heating reactor, start stirring and heat up to 45℃±2℃, mix and react for 2 hours, then put in sodium acrylate, continue to keep the temperature and stir for 1 hour, after cooling to room temperature, it will be discharged and packaged. It is a suspension product.

Embodiment 3

[0011] Example 3: Taking the preparation and synthesis of 100kg suspending agent as an example, weigh 3kg of industrial grade sodium hexametaphosphate, 1.5kg of industrial grade polyacrylamide, 2kg of industrial grade sodium acrylate, 93.5kg of purified water. Put sodium phosphate and polyacrylamide into the electric heating reactor, start stirring and heat up to 45℃±2℃, mix and react for 2 hours, then put in sodium acrylate, continue to keep the temperature and stir for 1 hour, after cooling to room temperature, it will be discharged and packaged. It is a suspension product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com