Production method for travertine-like ceramic tiles

A production method and technology of ceramic tiles, which are applied in the field of building materials, can solve the problems of less change in color and texture, less real texture than glazed tiles, rich and delicate patterns, and incapable of rich and changeable brick surface designs, etc., achieving a high degree of simulation and enhanced three-dimensional Visual effects, colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

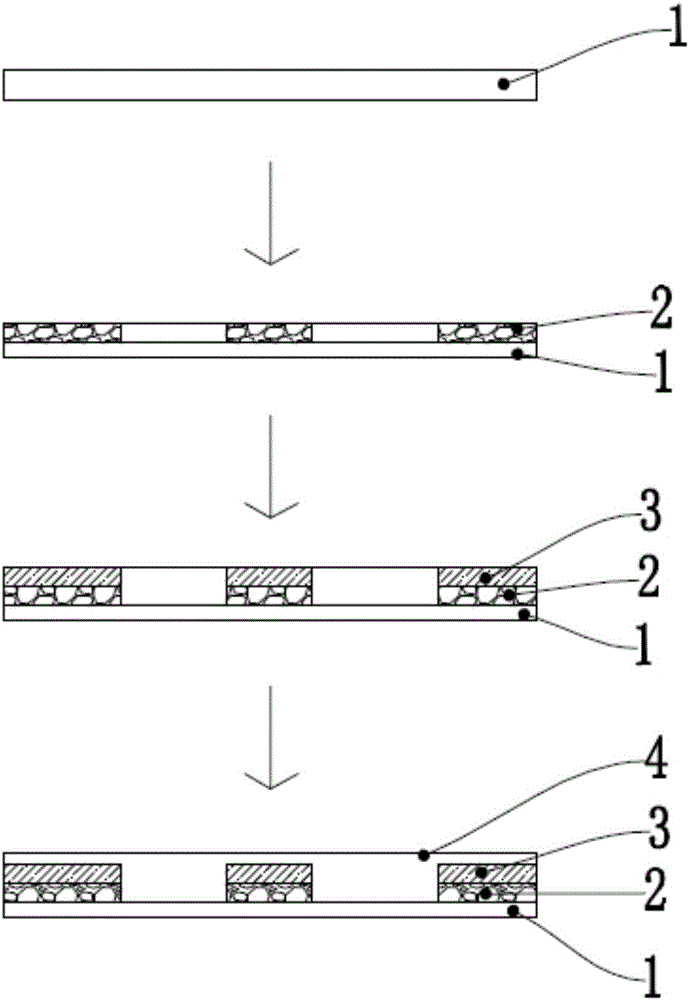

[0048] The adobe structure used in the following examples, the powder chemical composition (wt%) of its adobe layer is: SiO 2 : 70%, Al 2 o 3 : 21%, CaO: 1%, MgO: 2%, K 2 O: 2%, Na 2 O: 3%, Fe 2 o 3 : 0.5%, TiO 2 : 0.5%, prepare the powder according to the above proportioning ratio, press the prepared powder into adobe and dry it for subsequent use;

[0049] The chemical composition of its low-temperature glaze: SiO 2 : 30%, PbO: 65%, Al 2 o 3 : 3%, (Na 2 O, K 2 O): 1%, MgO: 1%, the viscosity of the low-temperature glaze prepared by mixing and ball milling is 9000mpa.s, the specific gravity is 1.7, and the softening point of the low-temperature glaze is 850°C.

[0050] The chemical composition (wt%) of its transparent glaze is: NaO: 1.5%; KO: 2%; AlO: 11%; CaO: 8%; MgO: 5%; ZnO: 2%; ZrO: 4%; Block: 15%; Loss on ignition: 6%; SiO 45.5%. The flow rate is 40s and the specific gravity is 1.75. It should be noted that the transparent glaze can be selected from the for...

Embodiment 2

[0057] Use same brick adobe and transparent glaze as embodiment 1;

[0058] The chemical composition of its low-temperature glaze: SiO 2 : 40%, PbO: 55%, Al 2 o 3 : 3%, (Na 2 O, K 2 O): 1%, MgO: 1%, the viscosity of the low-temperature glaze prepared by mixing and ball milling is 10000mpa.s, the specific gravity is 1.63, and the softening point of the low-temperature glaze is 800°C.

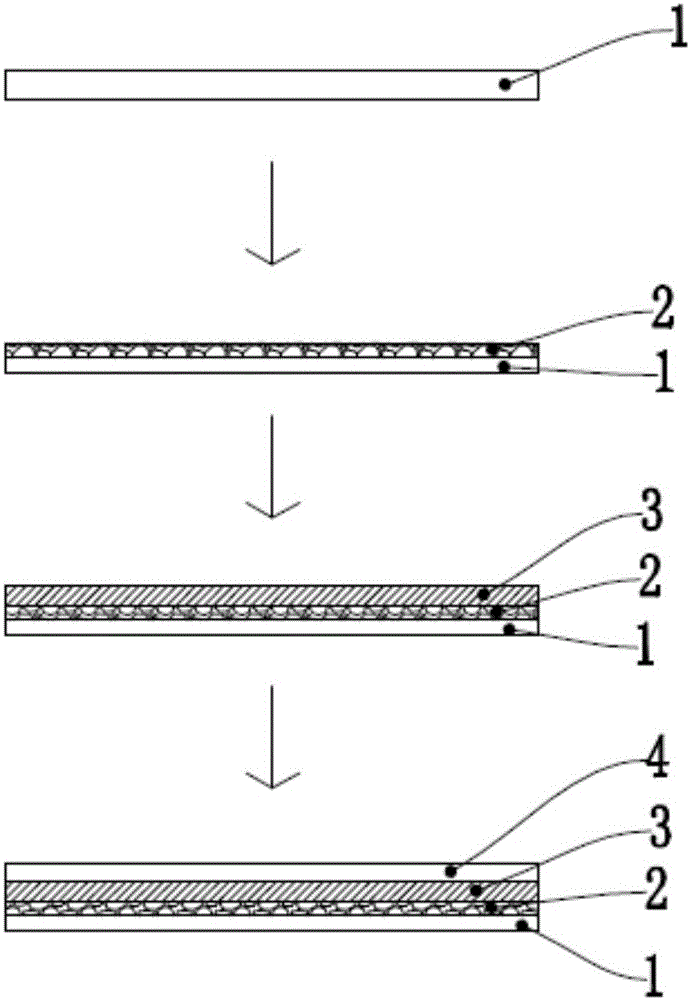

[0059] Another kind of production method of imitation travertine ceramic brick comprises the following steps (flow process can be seen Figure 5 shown):

[0060] A. Preparation of adobe: the surface of the adobe is polished by the adobe throwing machine to obtain the adobe surface with a clear pattern and texture;

[0061] B, distributing low-temperature glaze: distributing low-temperature glaze on the throw blank that step A obtains, low-temperature glaze is corresponding to the position that brick adobe surface is not provided with texture and adopts ink-jet printer to print, and thicknes...

Embodiment 3

[0066] Use same brick adobe and transparent glaze as embodiment 1;

[0067] The chemical composition of its low-temperature glaze: SiO 2 : 35%, PbO: 60%, Al 2 o 3 : 3%, (Na 2 O, K 2 O): 1%, MgO: 1%, the viscosity of the low-temperature glaze prepared by mixing ball milling is 9850mpa.s, the specific gravity is 1.83, and the softening point of the low-temperature glaze is 780°C.

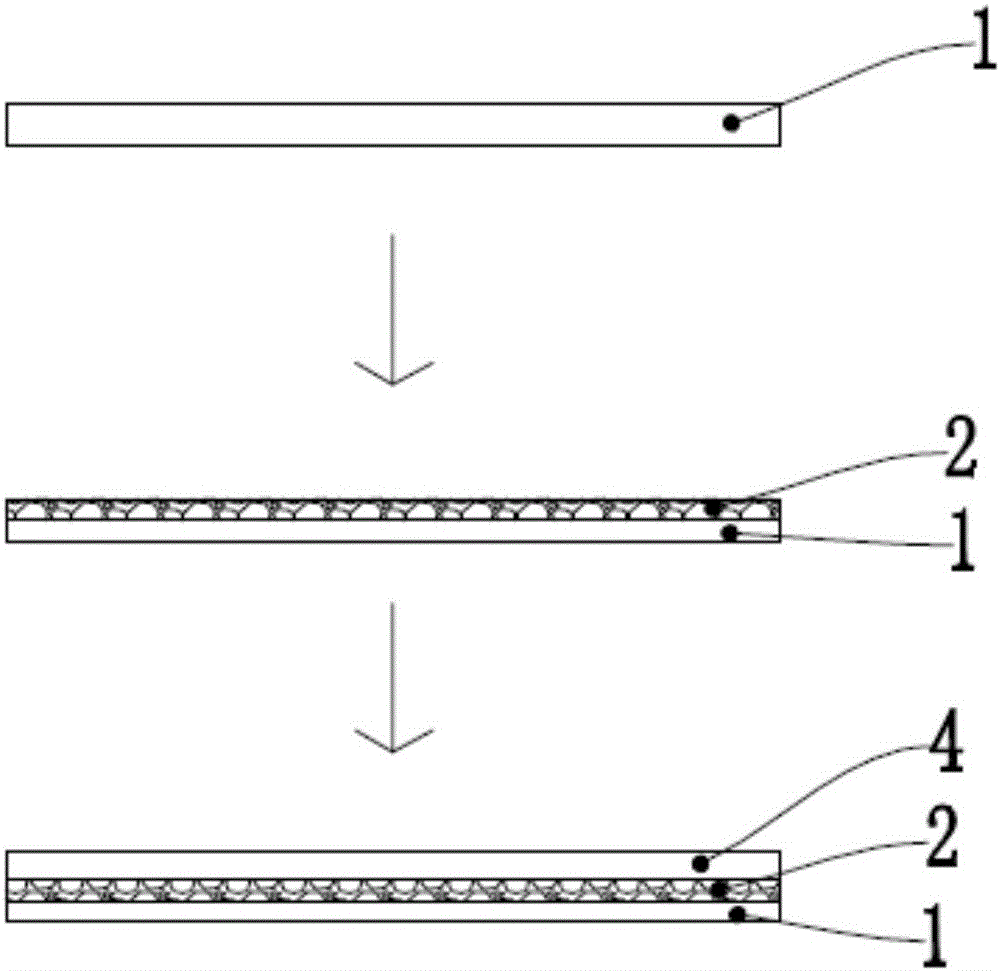

[0068] A kind of production method of imitation travertine ceramic tile, comprises the following steps (flow process can be seen figure 2 shown):

[0069] A. Preparation of adobe: the surface of the adobe is polished by the adobe throwing machine to obtain the adobe surface with a clear pattern and texture;

[0070] B, distributing low-temperature glaze: distributing low-temperature glaze on the cast blank obtained in step A, low-temperature glaze is corresponding to the pattern texture of brick adobe surface and adopts silk screen to carry out distribution, and the mesh number of screen is 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com