Cerium and erbium-doped silicate long-afterglow light-emitting material and preparation method thereof

A technology of long afterglow luminescence and silicate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effect of improving chemical stability and thermal stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

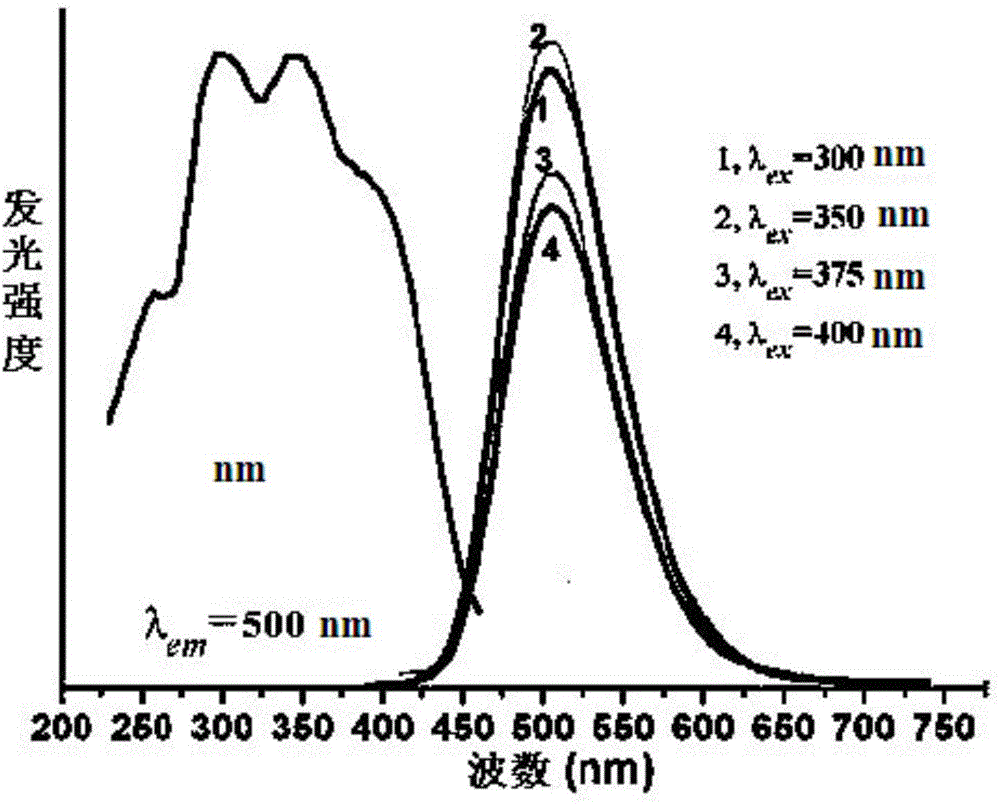

Image

Examples

Embodiment 1

[0018] A preparation method of a silicate long-lasting luminescent material doped with cerium and erbium, comprising the steps of:

[0019] 1) Ba(NO 3 ) 2 ,Mg(NO 3 )·6H 2 O,H 2 SiO 3 ,Mn(CH 3 COO) 2 , Ce(NO 3 ) 2 ·6H 2 O,Er 2 o 3 Weigh according to the ratio of substances 1:2.000:2.000:0.150:0.0080:0.0050, pre-fire at 800°C for 4 hours after fully grinding;

[0020] 2) the product obtained in step 1) is added with 12% H 3 BO 4 (AR) is used as a co-solvent, after grinding, the temperature is raised to 1200 ° C, kept for 8 hours, cooled to room temperature naturally, and the obtained product is ground again.

[0021] The nominal composition is: Ba 2+ ,2Mg 2+ ,2SiO2 3 2- ,0.150Mn 2+ ,0.008Ce 2+ ,0.010Er 3+ .

Embodiment 2

[0023] A preparation method of a silicate long-lasting luminescent material doped with cerium and erbium, comprising the steps of:

[0024] 1) Ba(NO 3 ) 2 ,Mg(NO 3 )·6H 2 O,H 2 SiO 3 ,Mn(CH 3 COO) 2 , Ce(NO 3 ) 2 ·6H 2 O,Er 2 o 3 Weigh according to the ratio of substances 1:2.300:2.300:0.170:0.0098:0.0080, pre-calcine at 900°C for 4 hours after fully grinding;

[0025] 2) the product obtained in step 1) is added with 15% H 3 BO 4 (AR) is used as a co-solvent, after grinding, the temperature is raised to 1300 ° C, kept for 10 hours, cooled to room temperature naturally, and the obtained product is ground again.

[0026] The nominal composition is: Ba 2+ ,2.3Mg 2+ ,2.3SiO2 3 2- ,0.170Mn 2+ ,0.0098Ce 2+ ,0.016Er 3+ .

Embodiment 3

[0028] A preparation method of a silicate long-lasting luminescent material doped with cerium and erbium, comprising the steps of:

[0029] 1) Ba(NO 3 ) 2 ,Mg(NO 3 )·6H 2 O,H 2 SiO 3 ,Mn(CH 3 COO) 2 , Ce(NO 3 ) 2 ·6H 2 O,Er 2 o 3 Weigh according to the ratio of substances 1:2.000:2.300:0.160:0.0090:0.0060, pre-fire at 900°C for 4 hours after fully grinding;

[0030] 2) the product obtained in step 1) is added with 18% H 3 BO 4 (AR) is used as a co-solvent, after grinding, the temperature is raised to 1250 ° C, kept for 8 hours, cooled to room temperature naturally, and the obtained product is ground again.

[0031] The nominal composition is: Ba 2+ ,2Mg 2+ ,2.3SiO2 3 2- ,0.160Mn 2+ ,0.009Ce 2+ ,0.012Er 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com