Single pipe style multifunctional vacuum refining system and method thereof

A vacuum refining and multi-functional technology, applied in the field of metallurgy, which can solve the problems of scrapping the whole furnace and low refining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

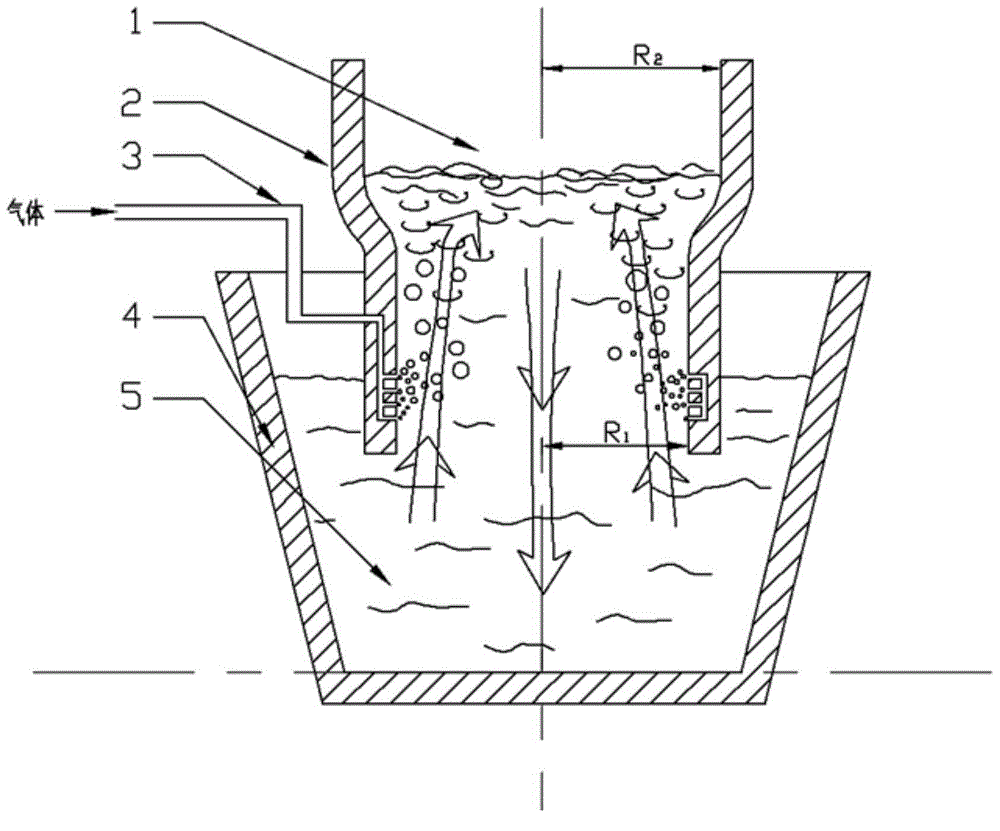

[0089] 80 tons of single-tube multifunctional refining furnace decarburization as an example.

[0090] 1) The relevant parameters are as follows:

[0091] (1) The total mass of molten steel is 80 tons, that is, W=80000Kg;

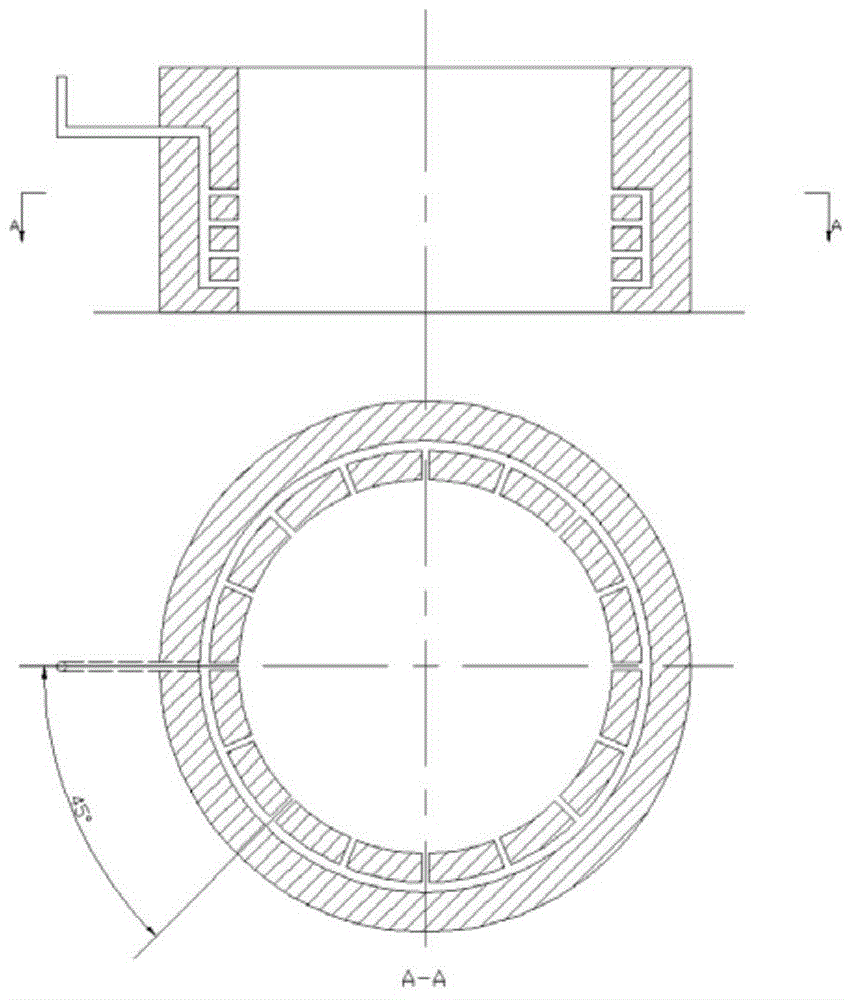

[0092] (2) The inner diameter of the single dipping tube is 1 meter, and the outer diameter is 1.68 meters. Set up three layers of argon blowing pipes at 200mm, 260mm, and 320mm from the lower end of the dipping tube, 24 per layer, the diameter of the hole is Φ0.002m, and the arrangement of argon blowing pipes between layers is staggered;

[0093] (3) The diameter of the top of the ladle is 2.595 meters, the diameter of the bottom is 2.275 meters, and the height is 3.2 meters;

[0094] (4) The depth of dipping a single dipping tube into molten steel is 0.4 meters. When the vacuum degree is 67 Pa, the height of molten steel in the dipping tube is 1.46 meters;

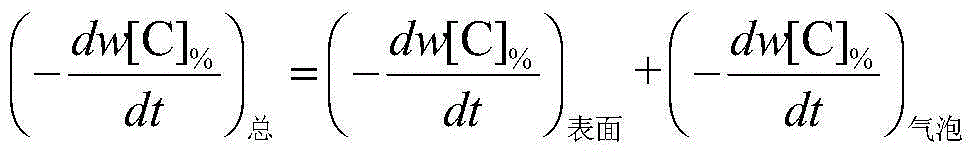

[0095] (5) The depth of molten steel under the external atmosphere is 2.435 meters, and the tot...

Embodiment 2

[0101] 80 tons of single-tube multifunctional refining furnace desulfurization as an example.

[0102] 1) The relevant parameters are the same as the implementation case 1.

[0103] 2) The desulfurization process implemented on IF steel using this single-tube multifunctional vacuum refining furnace:

[0104] Sampling of molten steel smelted from the converter for temperature measurement. The initial carbon content at the station is 0.04%, the initial oxygen content is 0.06%, the initial sulfur content is 0.0078%, and the slag thickness on the ladle liquid surface is 90mm.

[0105] First, insert the dipping tube into the molten steel. With the vacuuming, the liquid level in the vacuum chamber rises, and the liquid level in the ladle decreases. Keep the dipping tube inserted into the molten steel at a depth of 0.4m, and at the same time, the argon blowing flow rate is 100N / min; 3 Minutes later, when the vacuum degree in the vacuum chamber drops to 2000Pa, increase argon blowing ...

Embodiment 3

[0109] 80 tons of single-tube multifunctional refining furnace dehydrogenation as an example.

[0110] 1) The relevant parameters are the same as the implementation case 1.

[0111] 2) The dehydrogenation process implemented on GCr15 steel using this single-tube multifunctional vacuum refining furnace:

[0112] Sampling of molten steel smelted from the converter for temperature measurement. The initial hydrogen content at the station is 0.00035%, and the slag thickness on the ladle liquid surface is 80mm.

[0113] Before the dipping tube is inserted into the molten steel, blow argon with the venting brick at the bottom of the ladle, and set the flow rate of the argon blowing to 200N / min, so that the center part of the molten steel is exposed, and the slag flows close to the periphery of the ladle; insert the dipping tube, start vacuuming, and stop the ladle at this time Blow argon on the bottom ventilating brick, start the argon blowing device around the dipping tube, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com