Dedicated centrifugal tube and method for manufacturing cell blocks

A centrifuge tube and cell block technology, which is applied in the field of cytopathology, can solve the problems of the size and shape of the wax block, the inability to make a definite diagnosis of the patient, and the inability to make a cell block, so as to improve the positive rate of diagnosis and effectively It is beneficial to the quality control and standardized operation of cytopathology, and the effect of determining the location of cell distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with examples and accompanying drawings, but the present invention is not limited thereto.

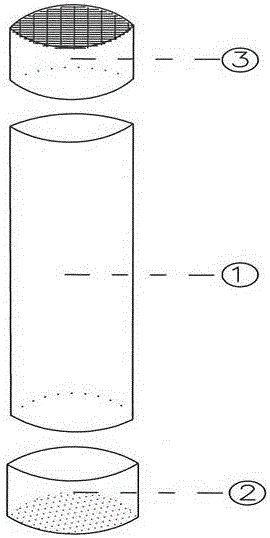

[0026] Such as figure 1 As shown, a special centrifuge tube for preparing cell blocks is composed of centrifuge tube ① and centrifuge tube caps ② and ③.

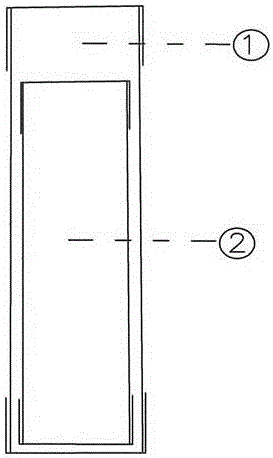

[0027] The centrifuge tube ① is open at both ends and is a cylindrical hollow tube with external threads on the outer surface of both ends (the external threads are not marked in the figure). Centrifuge tube caps ② and ③ are flat-bottomed, with a sealing ring (gasket) on the bottom of the cap (the sealing ring is not marked in the figure), and a closed type cap with internal threads on the surface of the inner wall (internal threads are not marked in the figure). The flat bottom is the structural basis for cells to be able to distribute on a flat surface. The centrifuge tube caps ② and ③ can be tightly engaged with the external threads at both ends of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com