Inspection system and method for reactor pressure vessel bottom head penetrations

A pressure vessel and inspection system technology, applied in reactors, nuclear reactor monitoring, nuclear power generation, etc., can solve problems such as installation and working environment that cannot be realized, and achieve the effects of reducing the difficulty of inspection operations, small volume, weight, and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0034] A reactor pressure vessel bottom head penetration inspection system, which includes a mechanical scanning unit, an ultrasonic / eddy current / video nondestructive testing unit, an electrical control unit that controls the action of the mechanical scanning unit, and an ultrasonic / eddy current / video nondestructive testing unit Each has an ultrasonic probe / eddy current probe / camera, and the mechanical scanning section includes an outer wall inspection device 1, an inner wall inspection device 2, an operating platform, and a long length between the operating platform and the outer wall inspection device 1 or inner wall inspection device 2. rod assembly3.

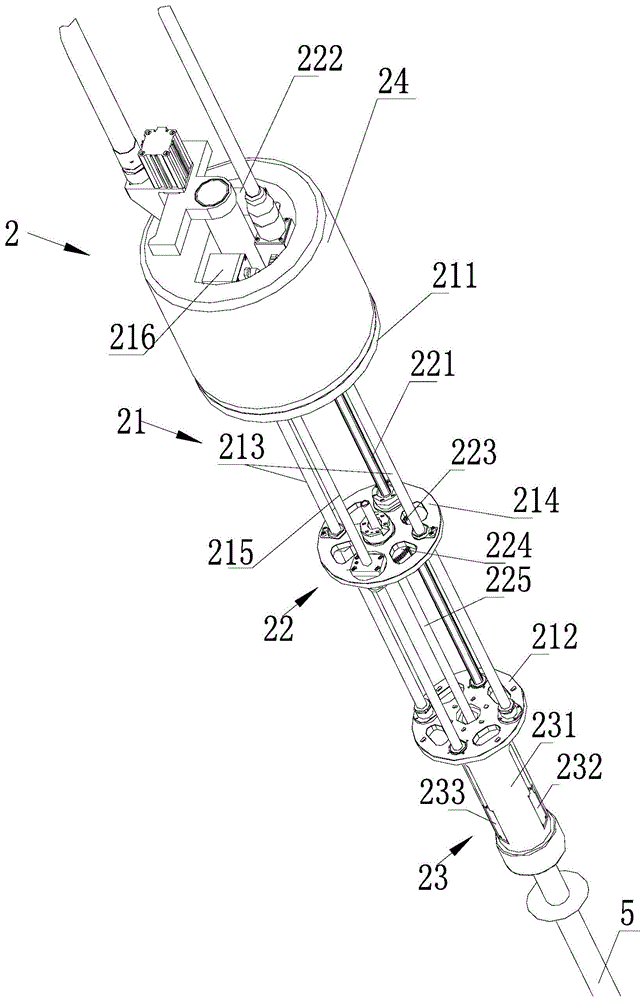

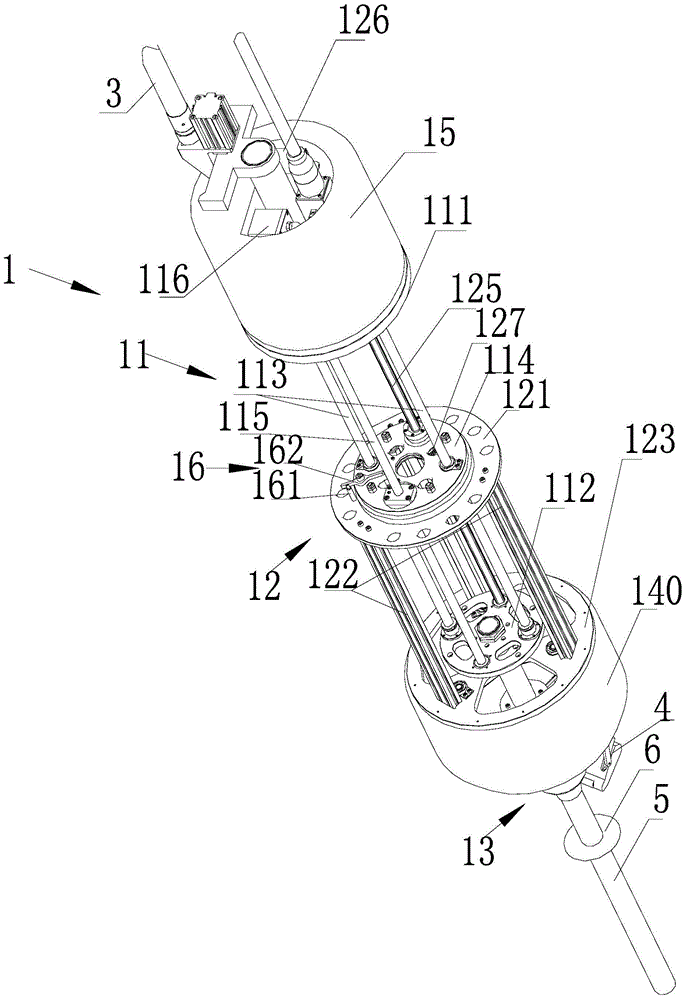

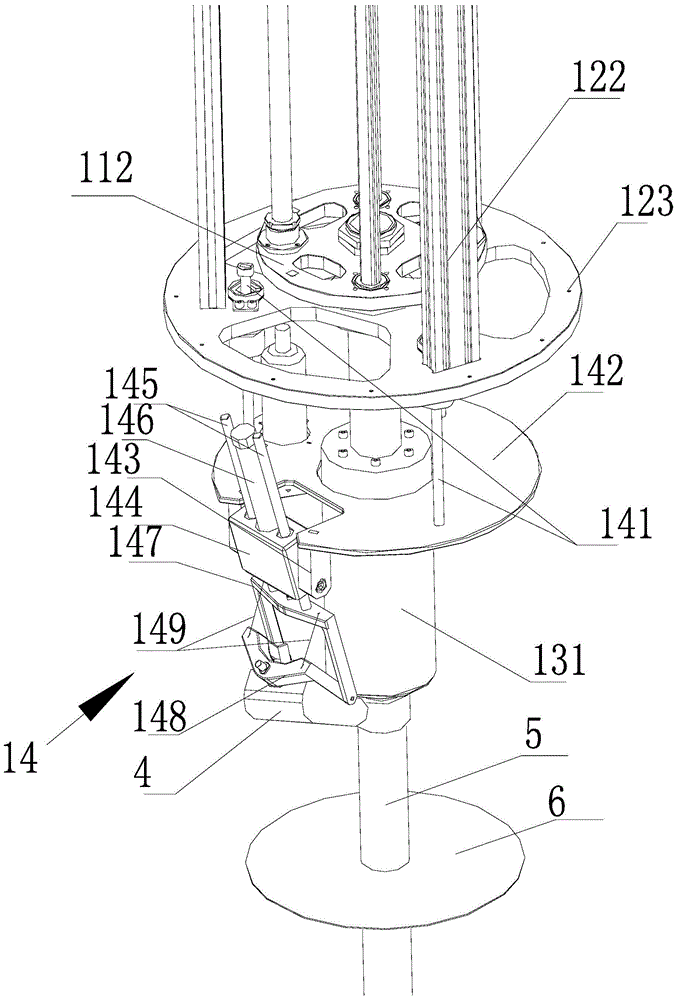

[0035] Such as figure 2 , 3 As shown, the outer wall inspection device 1 includes an adaptive mechanism 14 for installing and enabling the eddy current probe 4 to always be in clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com