Distributed feedback laser with short cavity length

A distributed feedback and laser technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of complex manufacturing process, technical difficulty, and complex process, and achieve the goal of improving feedback, direct modulation bandwidth, and slope efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

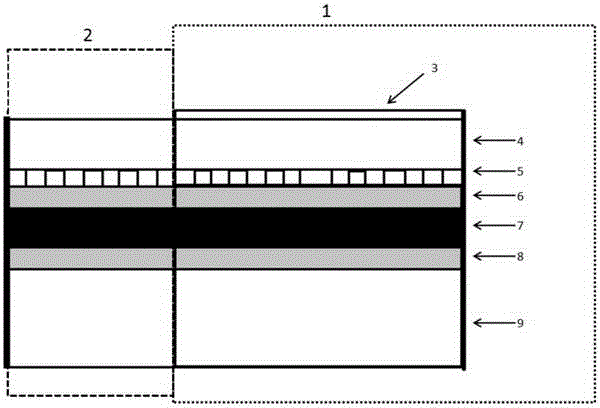

[0023] Such as figure 1 As shown, the distributed feedback laser with short cavity length of the present invention includes an active region 1, also known as an optical gain region and a reflection region 2, and the active region 1 includes an electrode contact layer 3, a waveguide upper cover layer 4, Grating layer 5 , upper optical confinement layer 6 , quantum well layer 7 , lower optical confinement layer 8 , and waveguide lower cover layer 9 . The reflective region 2 includes a waveguide upper cover layer 4 , a grating layer 5 , an upper optical confinement layer 6 , a quantum well layer 7 , a lower optical confinement layer 8 , and a waveguide lower cover layer 9 from top to bottom. The grating in the active region includes a phase shift region of λ / 4, and the gratings on both sides of the phase shift region are uniform gratings with the same period. The introduction of the phase shift region of λ / 4 makes the Bragg wavelength of the grating simultaneously the resonant w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com