Application of flavourzyme for fermenting and upgrading a cigar

A flavor protease and cigar tobacco technology, applied in the field of tobacco processing, can solve the problems of inability to decompose protein, low sugar-to-nitrogen ratio, and poor aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

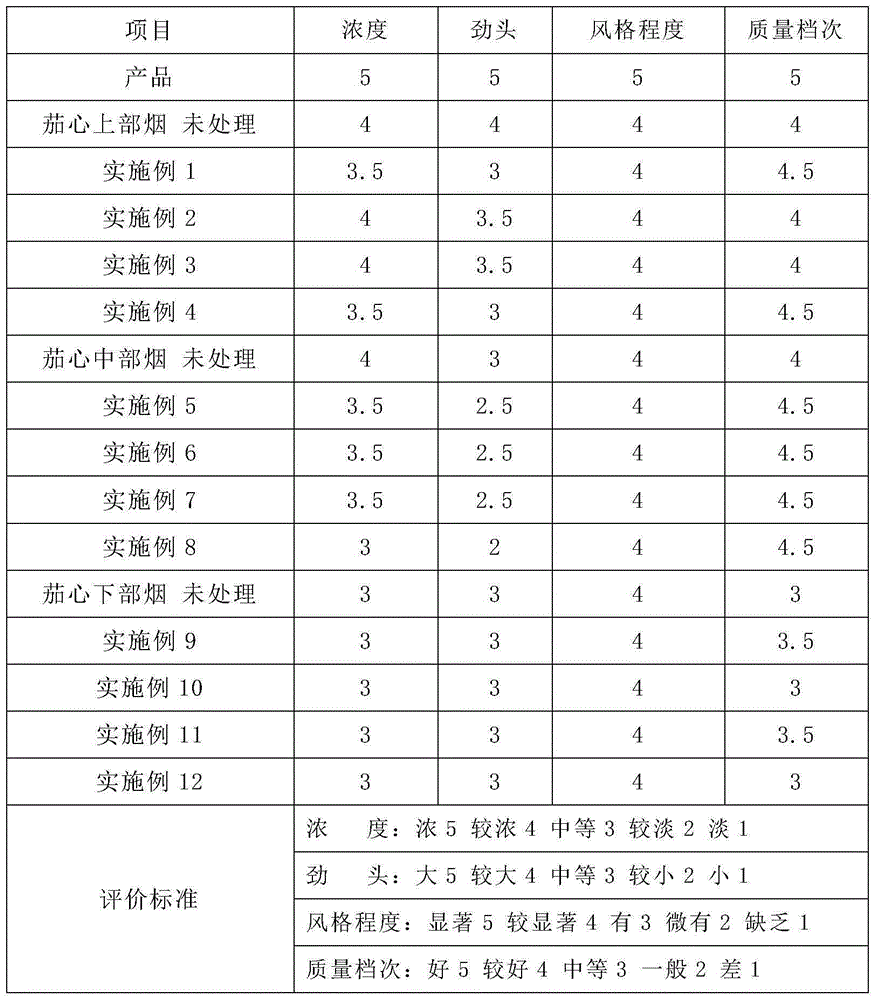

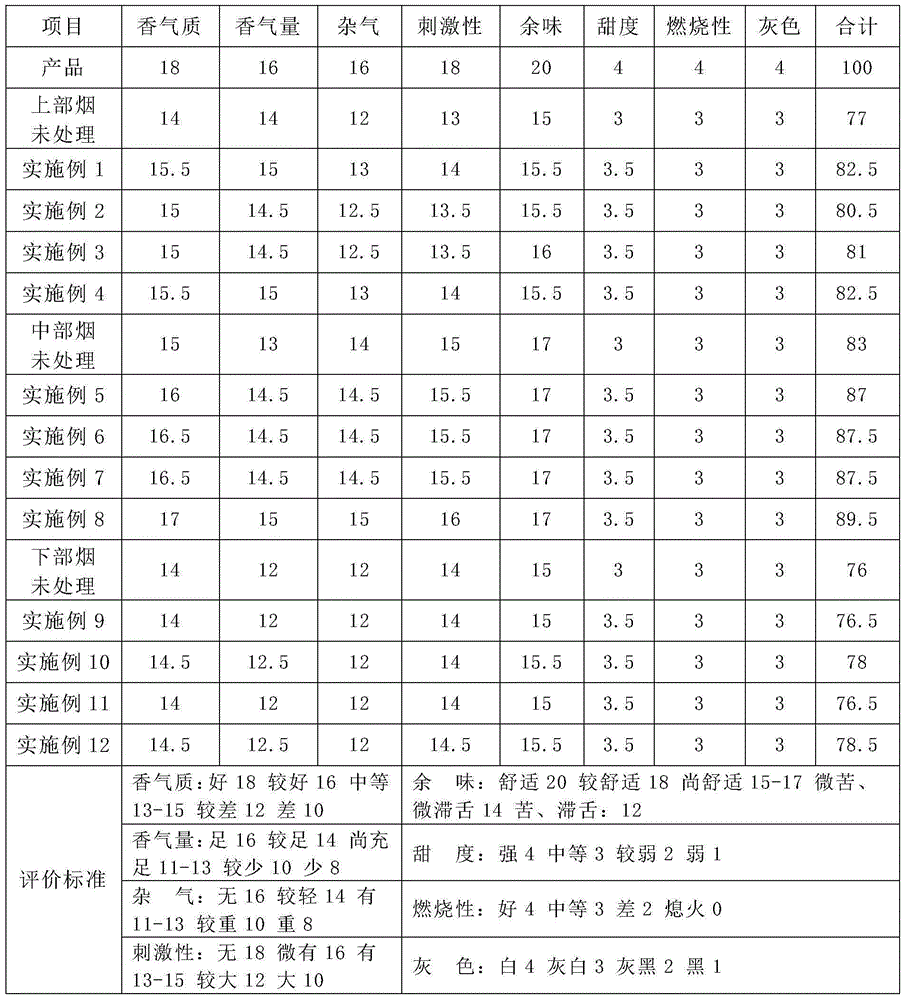

Examples

Embodiment 1

[0027] The application of flavor protease in cigar tobacco fermentation and quality improvement, the steps are as follows:

[0028] Flavor protease raw material is dissolved in pure water, and 10kg enzyme solution is prepared, and the enzymatic activity in the obtained enzyme solution is 1750U / ml (the density of obtained enzyme solution is 10 according to the density of pure water). 3 kg / m 3 calculate).

[0029] Vacuum the upper part of the above-mentioned cigar filler, humidify the tobacco leaves to a moisture content of 15%, soak the handle in 7kg of enzyme solution for 30 minutes, and then spray 3kg of enzyme solution (volume 3000ml) evenly on 30kg of tobacco leaves, that is, the enzyme solution The ratio of spray mass to tobacco leaf mass is 1:10, and the flavor protease activity corresponding to the enzyme solution spray in each gram of tobacco leaf (raw tobacco) is 175U. After standing still for 24 hours, after the moisture is balanced, the moisture content of the toba...

Embodiment 2

[0032] The application of flavor protease in cigar tobacco fermentation and quality improvement, the steps are as follows:

[0033] Flavor protease raw material is dissolved in pure water, and 10kg enzyme solution is prepared, and the enzyme activity in the obtained enzyme solution is 1200U / ml (the density of obtained enzyme solution is 10 according to the density of pure water). 3 kg / m 3 calculate).

[0034] After the upper part of the above-mentioned cigar filler is re-moisturized in a vacuum, it is humidified until the moisture content of the tobacco leaves is 16%. First, soak the handle in 6.25kg of enzyme solution for 30 minutes, and then spray 3.75kg of enzyme solution on 30kg of tobacco leaves evenly, that is, the spray quality of the enzyme solution The mass ratio of the tobacco leaf to the tobacco leaf is 1:8, and the corresponding flavor protease allocated to the spray of the enzyme solution in each gram of tobacco leaf (raw tobacco) is 150U. After standing still f...

Embodiment 3

[0037] The application of flavor protease in cigar tobacco fermentation and quality improvement, the steps are as follows:

[0038] Flavor protease raw material is dissolved in pure water, and 10kg enzyme solution is prepared, and the enzymatic activity in the obtained enzyme solution is 1500U / ml (the obtained enzyme solution density is 10 according to the density of pure water). 3 kg / m 3 calculate).

[0039] After the upper part of the above-mentioned cigar filler is re-moisturized in a vacuum, it is humidified until the moisture content of the tobacco leaves is 15%, and the handle is soaked in 7.5kg of enzyme solution for 30 minutes, and then 2.5kg of enzyme solution is sprayed evenly on 30kg of tobacco leaves, that is, the spray quality of the enzyme solution The mass ratio of the tobacco leaf to the tobacco leaf is 1:12, and the flavor protease corresponding to the spray of the enzyme solution in each gram of tobacco leaf (raw tobacco) is 125U. After standing still for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com