Efficient filter plate for dust collector

A filter, vacuum cleaner technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low enthusiasm for research and development, increase in motor temperature, secondary pollution, etc., to improve the impact of wind rebound , The effect of inhibiting the reverse flow of the air duct and increasing the self-adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

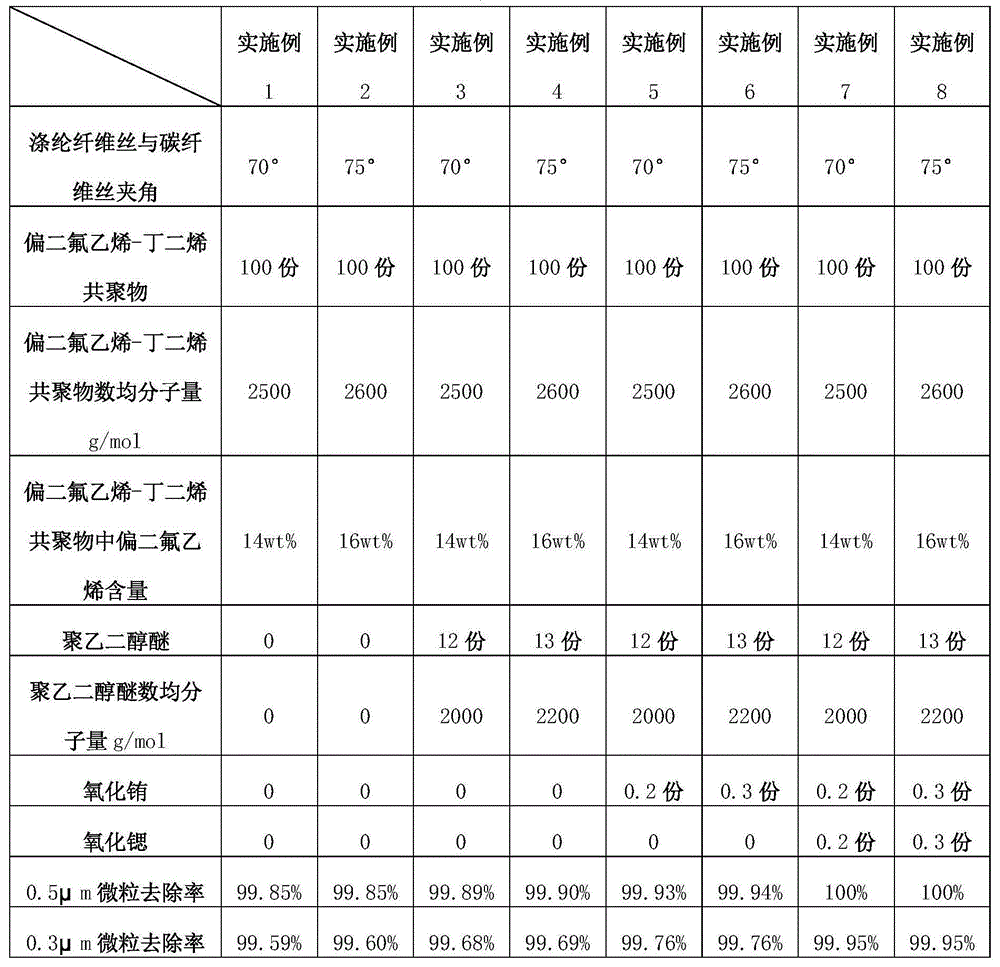

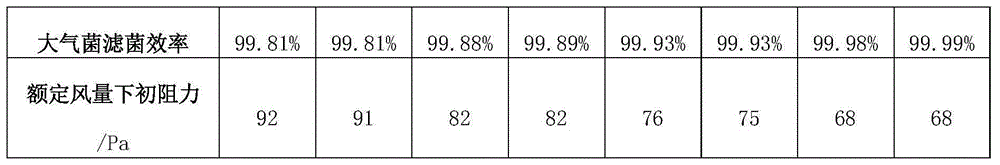

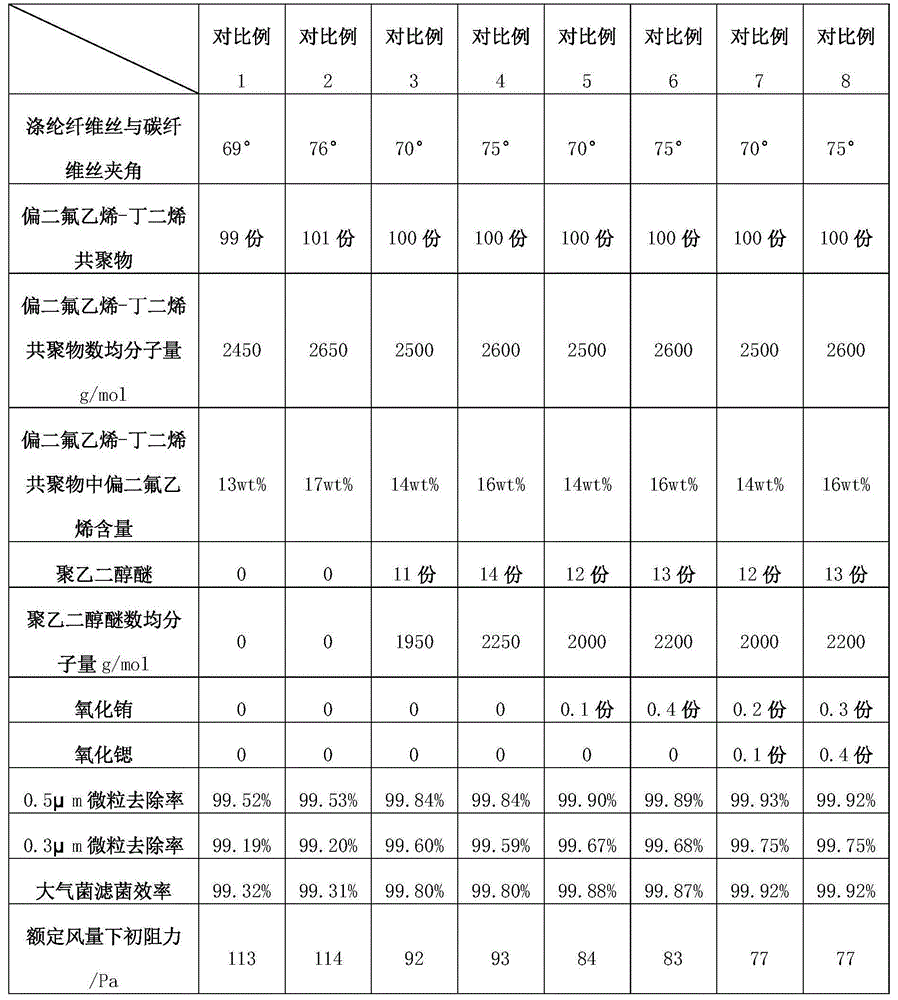

[0015] This case proposes an embodiment of a low-resistance filter for a vacuum cleaner, which includes a polyester fiber layer and a carbon fiber layer, wherein the fiber filaments in the polyester fiber layer and the carbon fiber layer are respectively arranged in one direction, and the fiber filaments in the polyester fiber layer are aligned with the carbon fiber layer. The fiber filaments in the layer are at an angle of 70-75°. Research has found that when the two layers of fiber filaments are at a certain angle, the angle can affect the wind resistance and filtering effect of the filter. Although it is more common to use two layers of fiber filaments perpendicular to each other in the prior art, from the actual wind resistance From the perspective of filtering effect, the angle be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com