Technology for extracting potassium and removing sodium from high-sodium polyhalite ore

A polyhalite and high-sodium technology, which is applied in the field of extracting and obtaining low-sodium polyhalite, can solve the problems of high-sodium polyhalite mine development and utilization that have not been reported, and achieve low comprehensive production cost, small investment, and water consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1) High sodium polyhalite ore (K 2 SO 4 · MgSO 4 2CaSO 4 2H 2 O content 60.12wt%, NaCl content 34.22wt%) ore grinding to -150 mesh (-0.106mm) accounted for 81.21wt%, the grinding method was ball milling, the grinding mass concentration was 50%, and the grinding medium was NaCl saturated mother liquor;

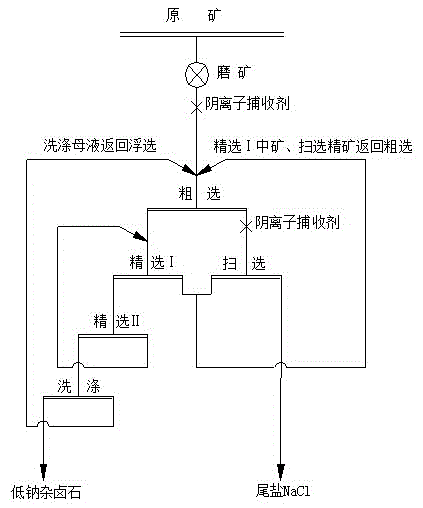

[0025] (2) In the NaCl saturated mother liquor, use one roughing, two beneficiation, one sweeping, beneficiation I medium ore, sweeping concentrate return to roughing, beneficiation II medium ore return to beneficiation I and return to the closed circuit Technological process, the roughing concentration is 29wt%, and the sweeping concentration is 21wt%; roughing adds anionic collector sodium dodecylsulfonate 150 g / ton, and the flotation time is 4 minutes, and sweeping adds anionic collector ten Sodium dialkyl sulfonate 75 grams / ton, flotation time is 3 minutes, be selected as do not add collecting agent twice s...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] (1) High sodium polyhalite ore (K 2 SO 4 · MgSO 4 2CaSO 4 2H 2 O content 76.72wt%, NaCl content 16.32wt%) ore grinding to -150 mesh (-0.106mm) accounts for 83.20wt%, the grinding method is ball milling, the grinding mass concentration is 60%, and the grinding medium is NaCl saturated mother liquor;

[0030] (2) In the NaCl saturated mother liquor, use one roughing, two beneficiation, one sweeping, beneficiation I medium ore, sweeping concentrate return to roughing, beneficiation II medium ore return to beneficiation I and return to the closed circuit Process flow, roughing concentration is 30.02wt%, sweeping concentration is 21.23wt%; adding anion collector sodium hexadecylsulfonate 180 g / ton in roughing, flotation time is 4 minutes, sweeping adding anion collection Sodium hexadecyl sulfonate is 75 grams / ton, and the flotation time is 3 minutes, and the selection is performed twice without adding a collector, a...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] (1) High sodium polyhalite ore (K 2 SO 4 · MgSO 4 2CaSO 4 2H 2 O content 52.99wt%, NaCl content 41.23wt%) ore grinding to -150 mesh (-0.106mm) accounts for 78.83wt%, the grinding method is ball milling, the grinding mass concentration is 65%, and the grinding medium is NaCl saturated mother liquor;

[0035] (2) In the NaCl saturated mother liquor, use one roughing, two beneficiation, one sweeping, beneficiation I medium ore, sweeping concentrate return to roughing, beneficiation II medium ore return to beneficiation I and return to the closed circuit Process flow, roughing concentration is 30.01wt%, sweeping concentration is 21.42wt%; adding anion collector sodium lauryl sulfate 125 g / ton in roughing, flotation time is 3 minutes, sweeping adds anion collector Sodium lauryl sulphate 50 grams / ton, flotation time is 3 minutes, and the selection is twice selection without collector, flotation time is 4 minutes; obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com