Toothed roll type cleaning method and device for shells and seeds of camellia oleifera

A Camellia oleifera shell and toothed roller technology is used in chemical instruments and methods, oil/fat production, solid separation, etc. to achieve the effects of prolonging residence time, reducing shell content and enhancing stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

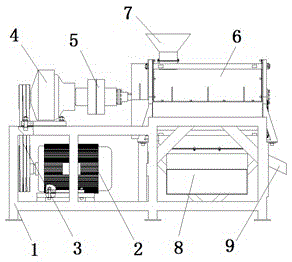

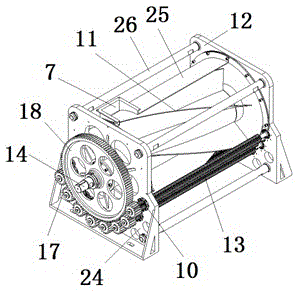

[0031] As can be seen from the accompanying drawings, the present invention relates to a toothed roller type camellia oleifera seed cleaning device, comprising a frame 1, a motor 2, a transmission device, a cleaning and separating body, a feed hopper 7, a shell outlet 17 and a seed outlet Port 18, the motor 2 is installed on the frame 1, and the power is transmitted to the cleaning and separating body through the transmission device; the cleaning and separating body is a toothed roller cleaning and separating body 6, and the gear roller cleaning and separating body 6 is equipped There is a toothed roller cleaning and separating device; the toothed roller cleaning and separating device has eight pairs of toothed roller groups arranged in the toothed roller cleaning and separating body.

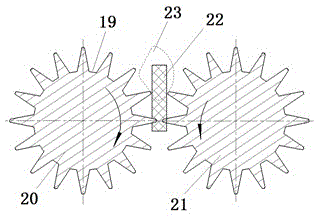

[0032] The toothed roller cleaning and separating device (such as image 3 shown) consists of a driving toothed roller 20 and a driven toothed roller 21, V-shaped grooves 19 are opened on both ...

Embodiment 2

[0042] The basic structure of embodiment two is the same as embodiment one, but the structure of the toothed rod is different (as attached Figure 4 shown), two toothed rods, wherein, the active toothed rod 220 has a V-shaped groove 219, and the driven toothed rod is a bachelor 221, and the steering of the active toothed rod 220 and the driven toothed rod 221 are opposite; through the teeth, The opposite roller of the smooth roller makes the camellia oleifera shell 22 dragged downward after being "caught" by the toothed roller under the interaction of the teeth and the smooth roller, and the camellia oleifera seed 23 will not be "caught" by the toothed roller due to its larger volume than the fruit shell. "Grab" to achieve the purpose of separating the shells and seeds. Although this embodiment does not have the clamping strength of the double V-shaped grooves, it can still basically achieve the effect of separating the shells and seeds of Camellia oleifera.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com