A system for recycling pasta food residues

A noodle processing and recycling technology, which is applied in the system field of noodle and food leftovers, can solve the waste of leftovers and other problems, and achieve the effects of avoiding waste, health protection, and increasing production added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

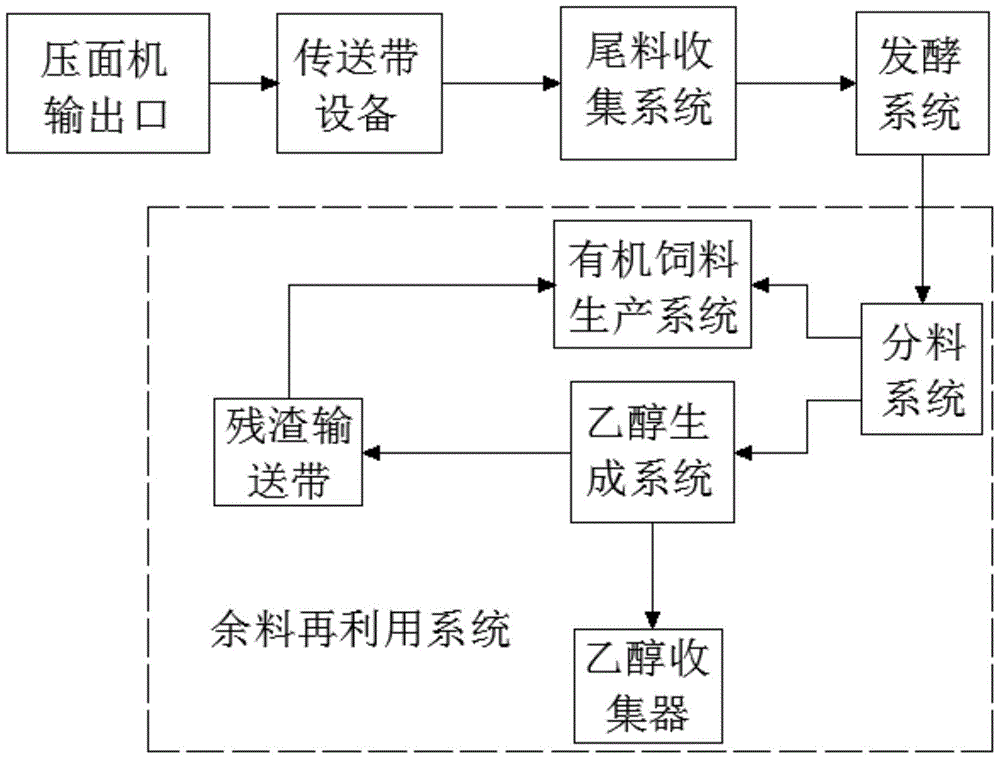

[0019] A system for resource processing of noodle leftovers, which solves the problem of waste of noodle leftovers generated during the existing noodle processing, and is designed for noodle processing, especially when customers need to reprocess vermicelli, etc. The high value-added reuse system for the remaining materials left in the edible noodle processing process can effectively avoid the waste of enterprises in the production and processing of noodle food, and at the same time effectively increase the wealth value of the enterprise, such as figure 1 As shown, it includes a noodle press output port, a tailings collection system, a fermentation system and a surplus material recycling system, the noodle press output port is connected to a tails collection system, the tails collection system is connected to a fermentation system, and the fermentation system The system is connected to the residual material recycling system; a material distributing system and an organic feed pr...

Embodiment 2

[0022] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, it is possible to conveniently and quickly transfer the remaining material left at the output port of the noodle press to the tail material collection system without adding additional manual input, such as figure 1 As shown, the following structure is particularly provided: a conveyor belt device is also included, the output port of the noodle press is connected to the conveyor belt device, and the conveyor belt device is connected to the tail material collection system.

[0023] In order not to increase manual input, the remaining material from the output port of the noodle press will be automatically conveyed to the tailing collection system connected with the conveyor belt equipment by the conveyor belt equipment. The tailing material collection system will be added to the fermentation system after pretreatment. Fermentation...

Embodiment 3

[0025] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, part of the leftover products after fermentation can be used for ethanol brewing together with crops such as grain sundries, such as figure 1 As shown, the following structure is particularly provided: an ethanol generation system is also provided in the residual material recycling system, and the ethanol generation system is connected with the distribution system.

[0026] In order not to increase manual input, the remaining material from the output port of the noodle press will be automatically conveyed to the tailing collection system connected with the conveyor belt equipment by the conveyor belt equipment. The tailing material collection system will be added to the fermentation system after pretreatment. Fermentation treatment, the leftover products after fermentation treatment will be sent to the material distribution syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com