Permanent locating segment assembling and welding method for rack and leg of drilling platform

A drilling platform, permanent technology, applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of difficult to guarantee welding quality, large welding deformation and stress, and high labor intensity of workers, so as to improve welding efficiency and reduce welding Stress, the effect of shortening the welding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

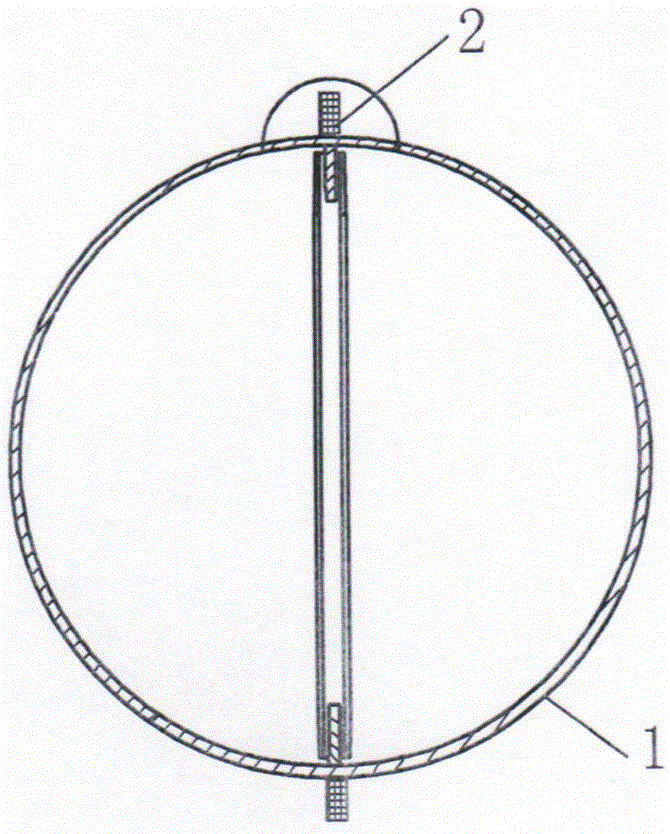

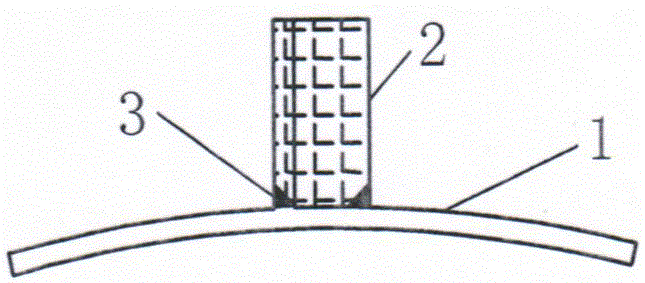

[0028] As shown in the figure, a rack 2 is installed on the pile leg 1, and the joint of the pile leg and the rack is welded and assembled through the welding point 3 of the permanent positioning section.

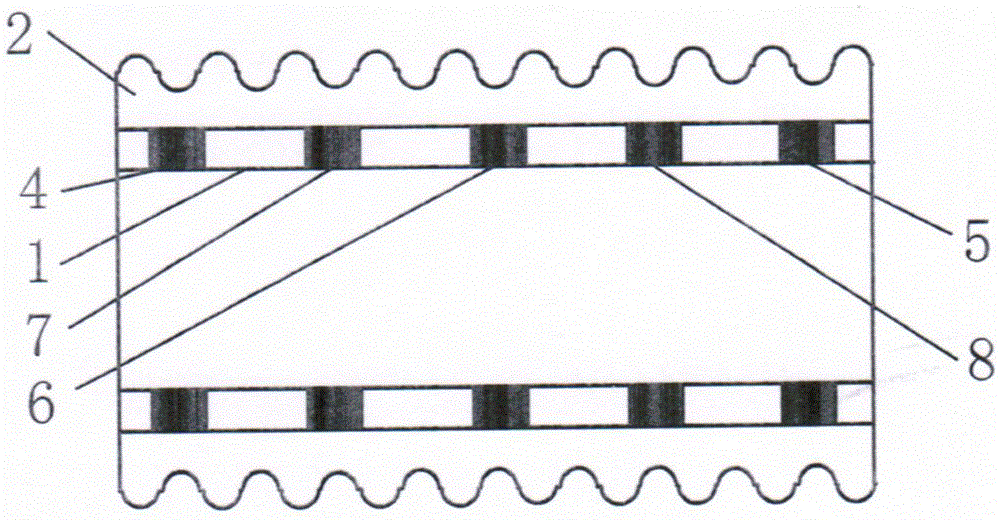

[0029] The welding points of the permanent positioning sections are the permanent positioning section 4 at the head end, the permanent positioning section 5 at the tail end, the permanent positioning section 6 in the middle, and the remaining permanent positioning sections 7 and 8 .

[0030] Each positioning segment is welded at the junction of the leg and the rack.

[0031] The method of assembling and welding the rack and the permanent positioning section of the leg, the specific implementation process is as follows:

[0032] Select the 4.8-meter rack and leg to be welded. Before welding, clean up the water, rust, oil, etc. on the surface of the area to be welded and within 20 mm on both sides; The rack is preheated; the permanent positioning section is welded. The lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com