Sound insulating board, preparation method thereof and door

A sound insulation board and door panel technology, which is applied in the field of building decoration materials, can solve the problems of high price and poor environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The application also provides a method for preparing a sound insulation board, comprising the following steps:

[0028] mixing the corn stalk inner core with a mass ratio of (20-30):(18-22) with a binder, and pre-pressing to obtain a slab;

[0029] The slab is pressurized and solidified to obtain a sound insulation board.

[0030] In the process of preparing the sound insulation board, the applicant firstly mixes the corn stalk core with the binder and pre-presses to obtain a slab, then pressurizes the slab, solidifies and shapes it, and obtains the sound insulation board.

[0031] The pressurized pressure is preferably 1.0-1.8 MPa, the temperature is 100-150° C., and the pressurized time is preferably 45-60 s.

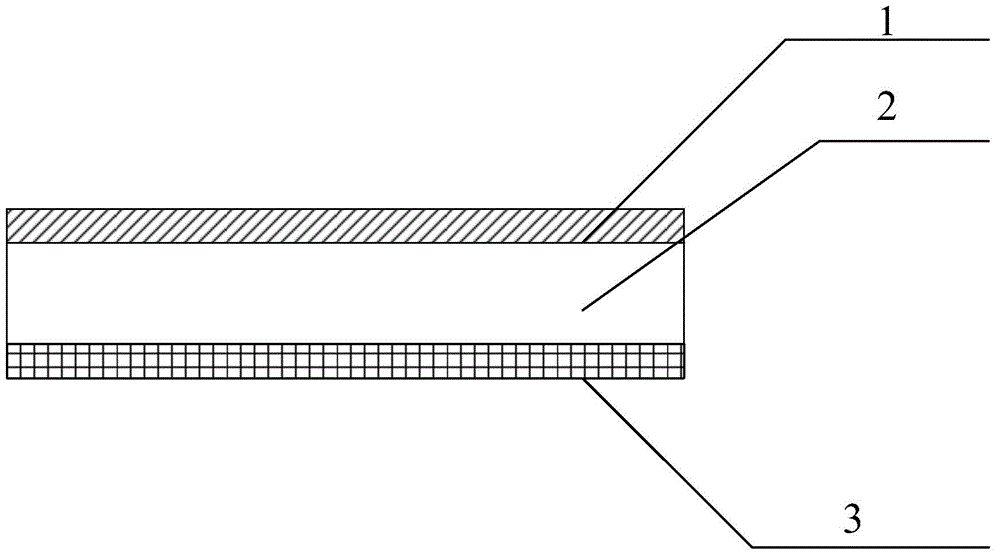

[0032] The present application also provides a door with a corn stalk core sound insulation board as the internal filling material, the door includes a first door panel, a sound insulation board and a second door panel arranged in sequence, and the sound insul...

Embodiment 1

[0037] Mix 25kg of corn stalk inner core with 20kg of binder, stir evenly, and pre-press into a billet, wherein the binder includes 18.75kg of urea-formaldehyde resin, 0.42kg of ammonium chloride and 0.83kg of paraffin, corn stalk The fiber length of the inner core is 100-150mm; then pressurize at 120°C to 1.5MPa, keep it for 45-60s, solidify and form, and obtain a sound insulation board.

Embodiment 2

[0039] Mix 20kg of corn stalk inner core with 18kg of binder, stir evenly, and pre-press into a billet, wherein the binder includes 17.16kg of urea resin, 0.08kg of ammonium chloride and 0.76kg of paraffin, corn stalk The fiber length of the inner core is 100-150mm, which is 75%, and the remaining fiber length is 200-300mm; then pressurize 1.5MPa at 120°C, keep for 45-60s, and solidify and form to obtain a sound insulation board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com