Highlight halogen-free flame-retardant PC/ABS composite material for electric appliance shell

A technology for electrical enclosures and composite materials, applied in the field of engineering plastics, can solve the problems of insufficient environmental protection of high-gloss paint, complex process steps, low production efficiency, etc., and achieve the effects of improving surface brightness and processing fluidity, simple production process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the embodiments, but the protection scope of the present invention is not limited to the following examples.

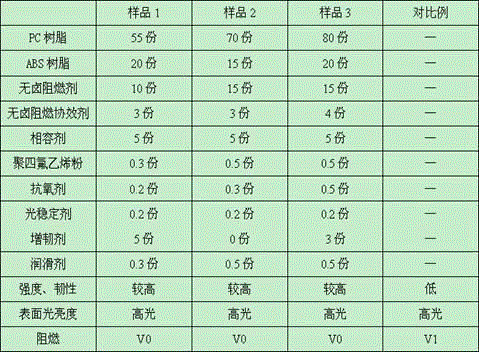

[0023] The technical solution adopted in this embodiment is: a high-gloss halogen-free flame-retardant PC / ABS composite material for electrical casings, mainly composed of the following components: 50-80 parts of PC resin, 10-30 parts of ABS resin, halogen-free flame-retardant 5 to 20 parts of non-halogen flame retardant synergist, 3 to 8 parts of compatibilizer, 0.3 to 0.8 parts of polytetrafluoroethylene powder, 0.1 to 0.5 parts of antioxidant, 0.1 to 0.5 parts of light stabilizer parts, toughening agent 0-10 parts, lubricant 0-1 part.

[0024] Among them, the PC resin is a polycarbonate with a weight average molecular weight of 30,000 to 50,000 and a density of 1.1 to 1.6 g / cm3, and the ABS re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com