A synthetic monoclinic structure vo with low phase transition temperature 2 Methods

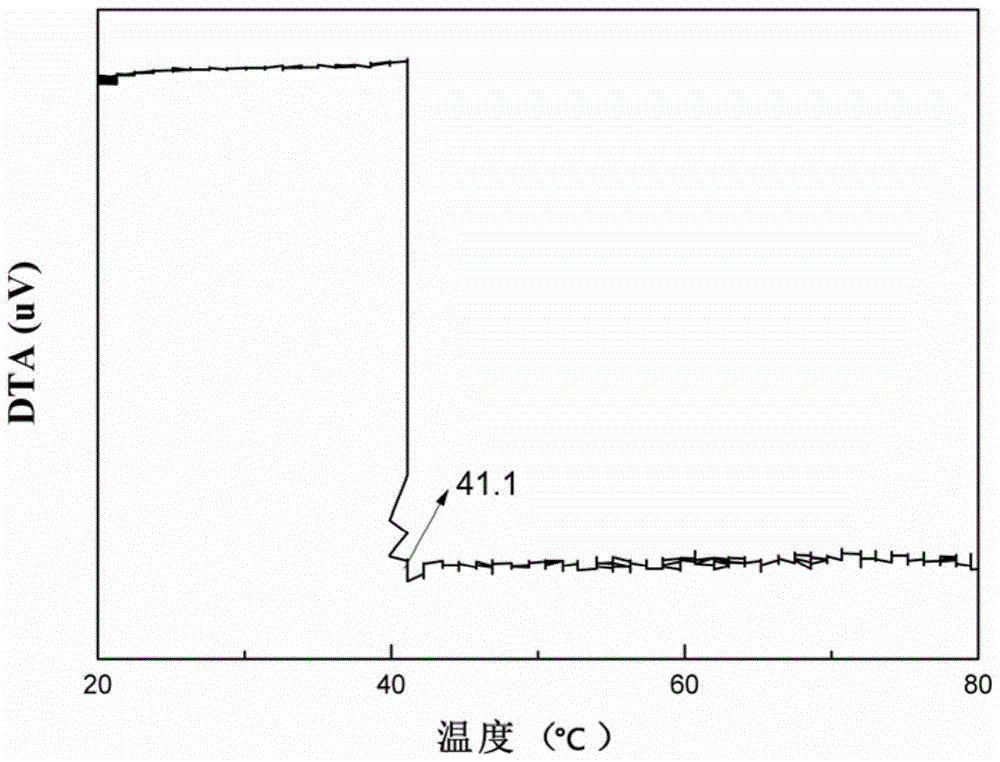

A phase transition temperature, VO2 technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high phase transition temperature and inability to realize up-conversion luminescence, etc., and achieve the effect of lower phase transition temperature and strong intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

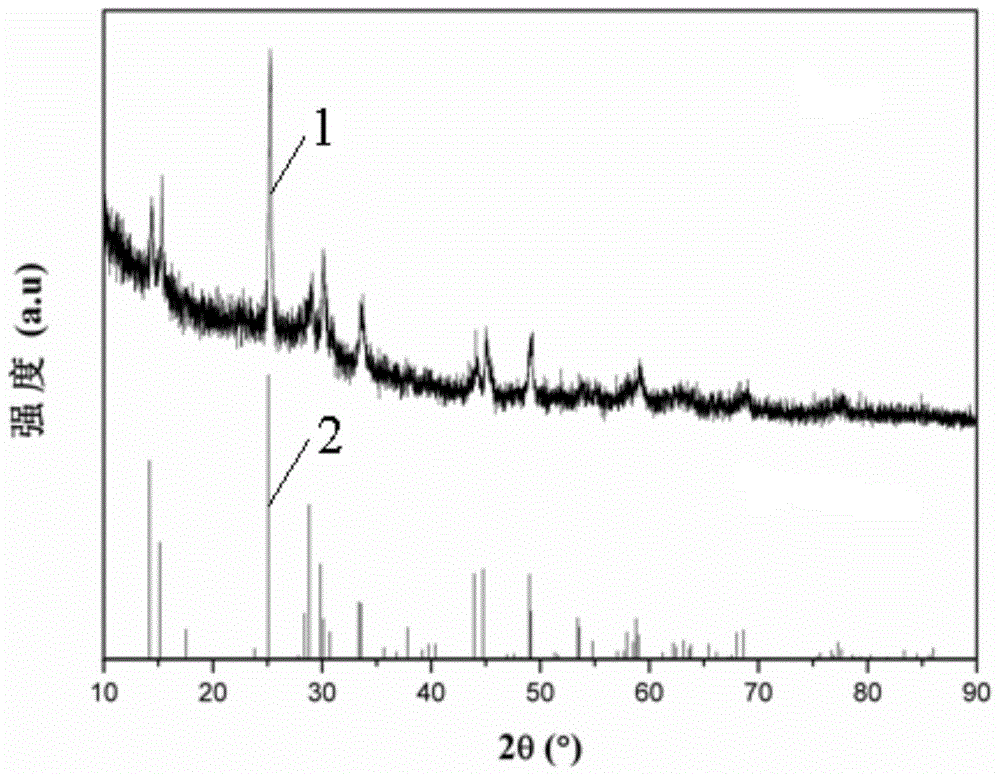

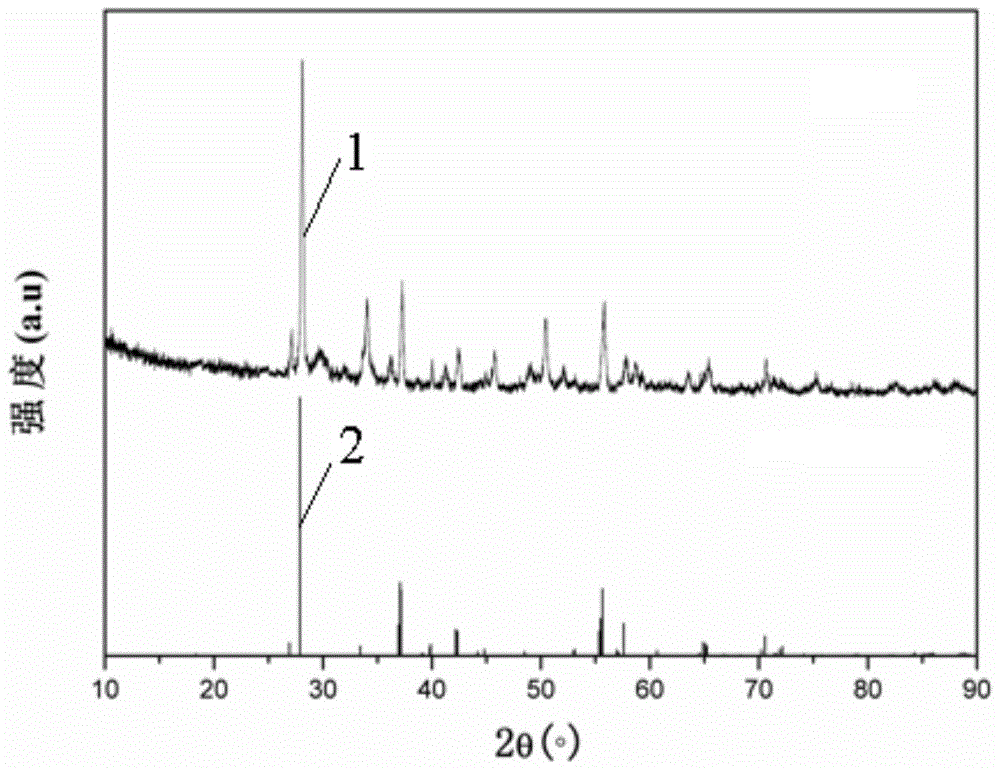

[0032] Specific embodiment 1: This embodiment is a synthesis of monoclinic structure VO with low phase transition temperature 2 The method is done in the following steps:

[0033] One, will Er 2 o 3 and Yb 2 o 3 Add it into nitric acid with a mass fraction of 65% to 68%, then heat it on a universal electric furnace with a power of 500W to 1000W for 10min to 20min, then add distilled water to obtain a mixed solution A;

[0034] Er described in step 1 2 o 3 with Yb 2 o 3 The molar ratio of the substance is 2:(4~10);

[0035] Er described in step 1 2 o 3 The volume ratio of the amount of substance and the mass fraction of 65%~68% nitric acid is 2mol:(2mL~10mL);

[0036] Er described in step 1 2 o 3The volume ratio of the amount of substance to distilled water is 2mol:(5mL~10mL);

[0037] Second, the V 2 o 5 Add oxalic acid and oxalic acid to the mixed solution A, then add distilled water, and stir at a stirring speed of 400r / min-600r / min for 2h-4h to obtain a blue...

specific Embodiment approach 2

[0054] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: Er described in step one 2 o 3 The mass fraction is greater than 99.99%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: Yb described in step 1 2 o 3 The mass fraction is greater than 99.99%. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com