Pickling system and pickling method

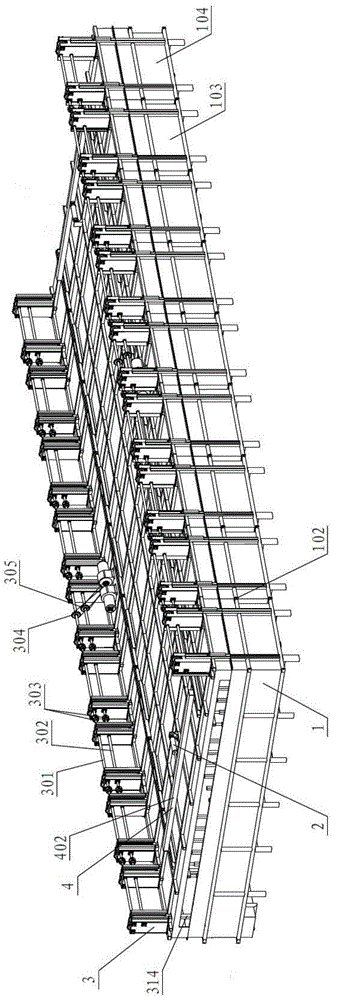

A technology of pickling and pickling tank, which is applied in the field of pickling system, and can solve the problems of plant and equipment corrosion, low pickling efficiency, missing plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

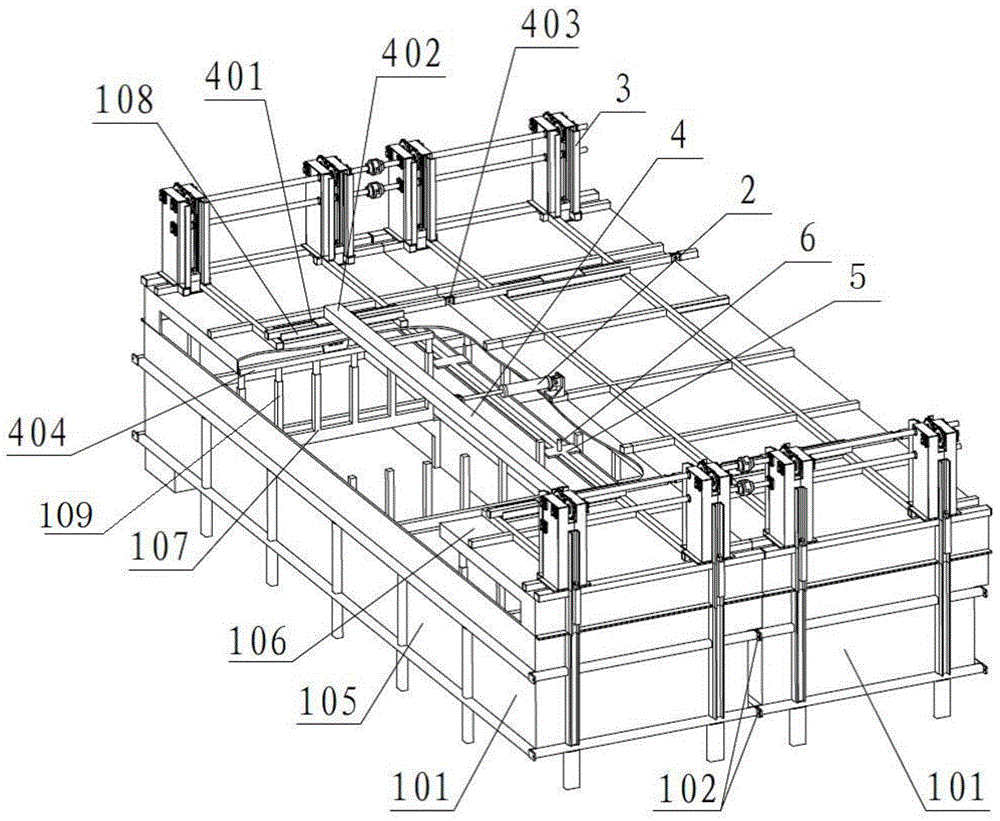

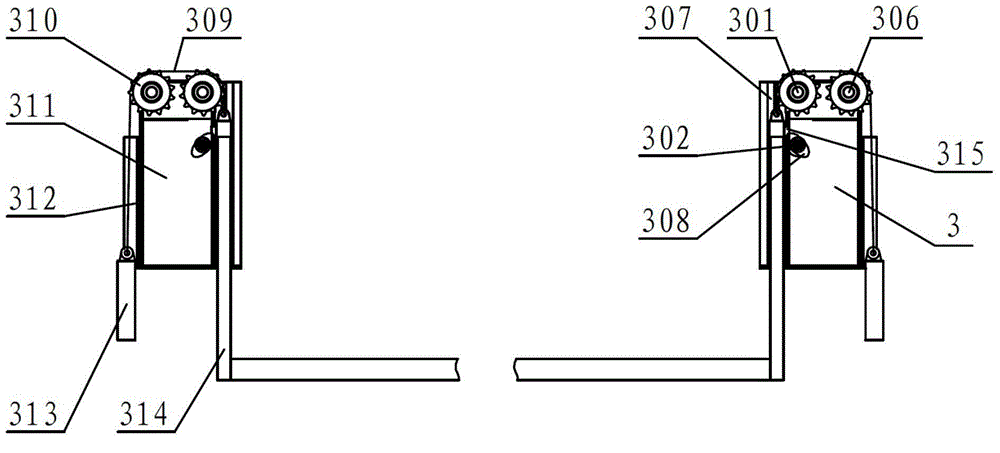

[0067] According to a specific embodiment of the present invention, the pickling tank 101 includes: a tank body 105; a tank body cover 106, which is sealedly mounted on the tank body 105; a fixing bracket 107, which is fixedly installed on the tank body 107 In the body 105, and the fixing bracket 107 is provided with a plurality of stations arranged along the length direction, and the parts to be pickled can be pickled in sequence at the plurality of stations. The tank cover 106 is used to seal the pickling tank 101 to prevent the acid mist generated during the pickling process from escaping and polluting the environment. The lifting seat 311 can be arranged on the tank cover 106 . A plurality of said stations can divide the parts to be pickled into groups so that they can be processed in batches. In addition, a sliding groove 108 may be provided on the groove cover 106, so that the lever link 401 can be accommodated to slide therein.

[0068] Further, the adjacent work stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com