Low-power magnetic resistance sensor based on LTCC technology and preparation method therefor

A magnetoresistive sensor, low power consumption technology, applied in the direction of instruments, measuring magnetic variables, manufacturing measuring instruments, etc., can solve the problems of photolithography, increased coating times, high energy consumption, and increased difficulty of sensors, etc., to achieve easy large-scale Realize, simplify the preparation process, and improve the effect of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a low-power magnetoresistive sensor based on LTCC technology provided by the invention, specifically comprises the following steps:

[0033] Step 1: Select non-magnetic LTCC microwave dielectric material as the casting substrate material, and use LTCC technology to make n-layer green ceramic tape diaphragm as the substrate;

[0034] Step 2: using silver paste to prepare the bottom coil by screen printing on the substrate obtained in step 1, and then preparing a green ceramic tape diaphragm on the bottom coil as the first green ceramic tape layer;

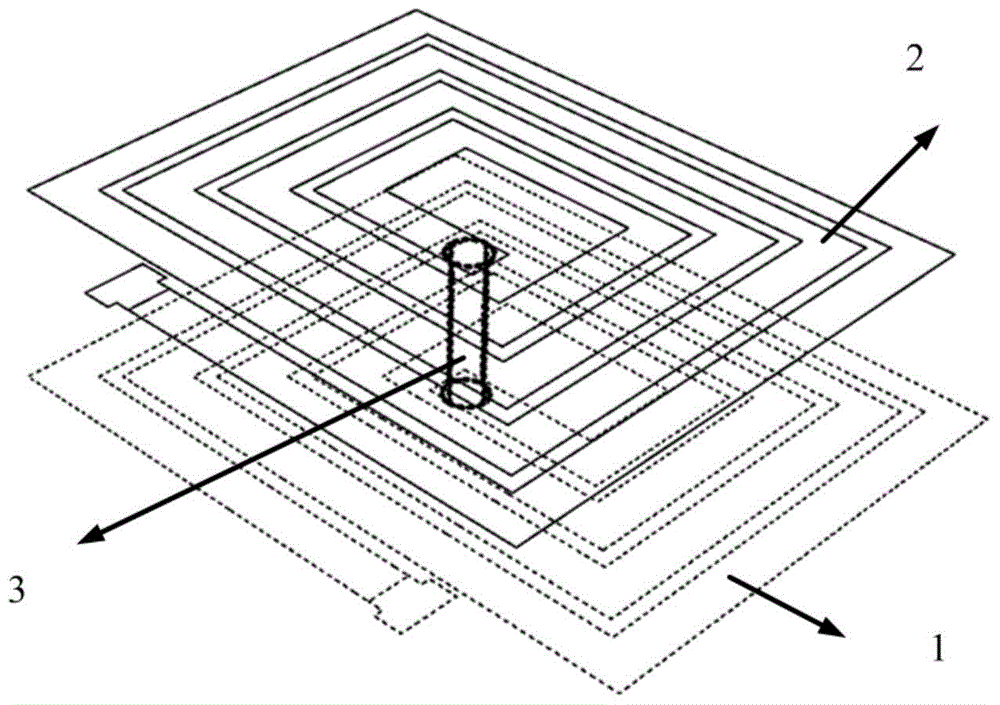

[0035] Step 3: Use silver paste to screen-print the top-layer coil on the first raw ceramic tape layer obtained in step 2, and connect the top-layer coil to the top-layer coil through the metal through hole in the center of the coil (using silver paste) to form a double-layer coupling layer of set / reset coils, such as figure 1 shown;

[0036] Step 4: Use LTCC technology to prepare 1-2 layers of green ...

Embodiment

[0040] A method for preparing a low-power magnetoresistive sensor based on LTCC technology, specifically comprising the following steps:

[0041] Step 1: Select Al 2 o 3 The LTCC material compounded with glass is used as the casting substrate material. Using LTCC technology, first stack about 400 μm green ceramic tape diaphragm to obtain the substrate;

[0042] Step 2: Use silver paste screen printing on the substrate obtained in step 1 to obtain the bottom coil, and then laminate a green ceramic tape diaphragm with a thickness of about 10 μm on the bottom coil as the first green ceramic tape layer ;

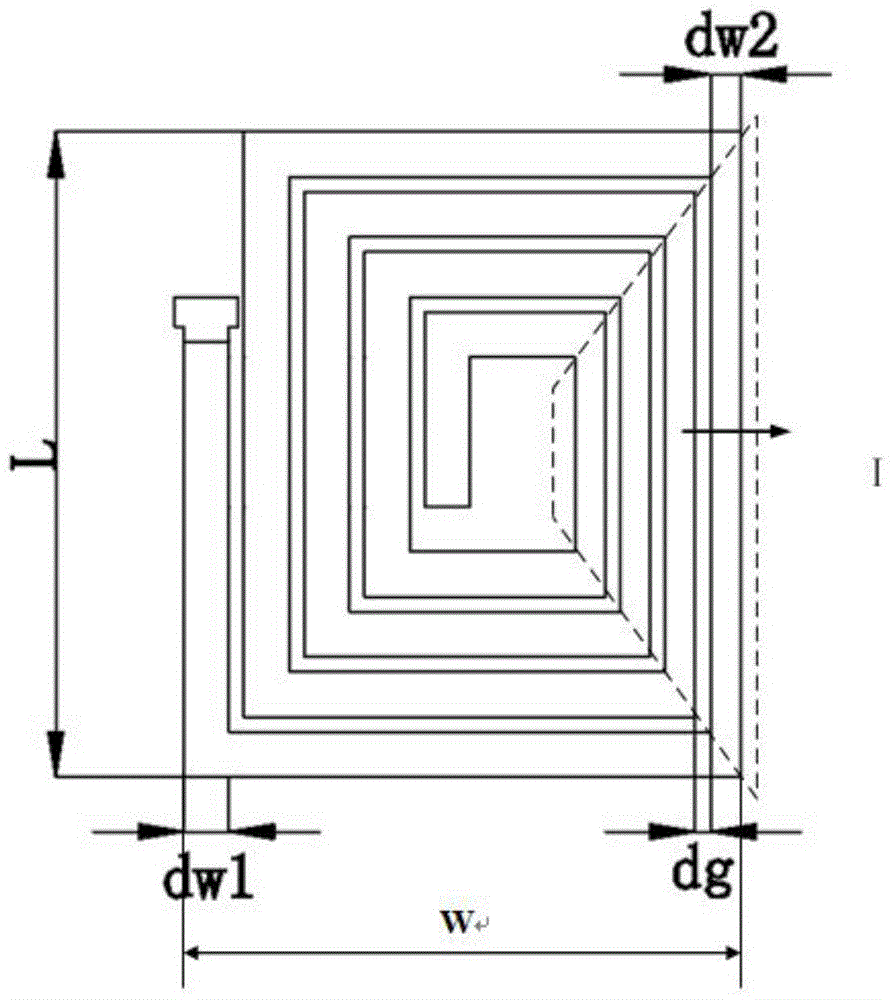

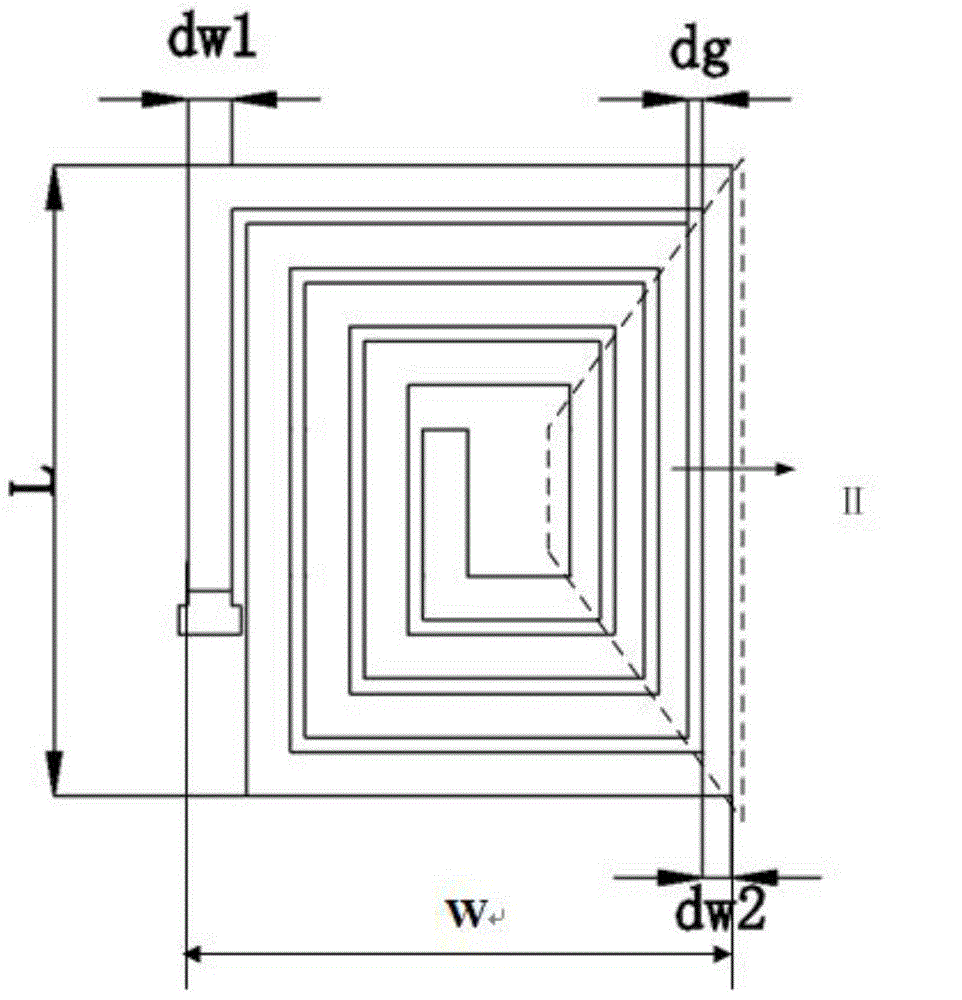

[0043] Step 3: On the first green tape layer obtained in step 2, use silver paste to screen-print the top layer coil, and connect the top layer coil to the top layer coil through the metal through hole in the center of the coil (using silver paste) to form a double layer A coupled set / reset coil layer, wherein the dimensions of the top and bottom coils are: dw1=60 μm, dw2=20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com