Fmoes officinalis ames chewing gum and making technology thereof

A production process and technology of chewing gum, applied in the direction of chewing gum, food science, application, etc., can solve the problems of unacceptable products, lack of Alihong products, and inability to make good use of the pharmacological activity of Alihong, so as to achieve moderate bitterness of chewing gum, Increase chewing taste, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

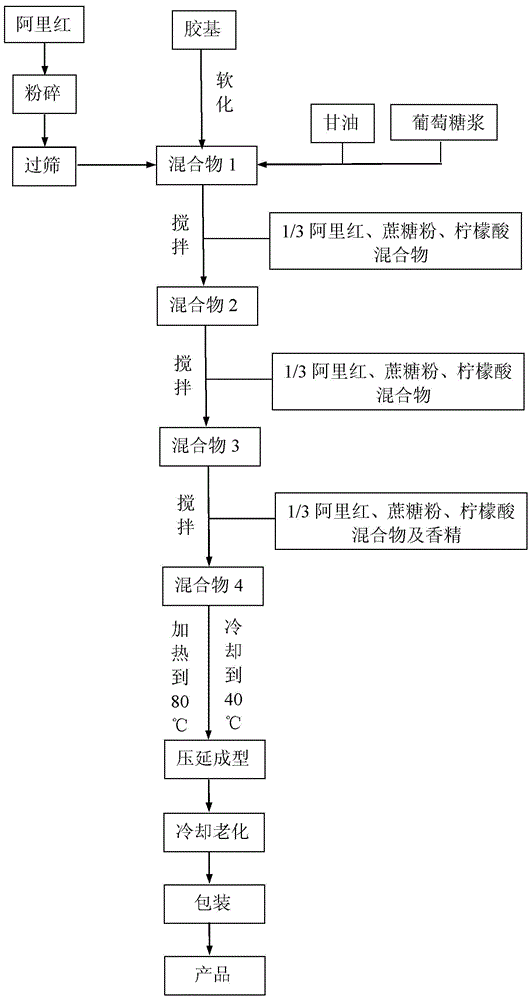

[0024] Specific embodiment one: Alihong chewing gum in this embodiment includes 30-40 parts of gum base, 0.5-3 parts of Alihong, 25-45 parts of sucrose powder, 0.1-1.0 parts of citric acid, 15-40 parts by weight. 35 parts of glucose syrup, 0.1-1.0 parts of essence and 1-5 parts of glycerin.

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that: Alihong chewing gum in this embodiment includes 32-38 parts of gum base, 1-2 parts of Alihong, and 30-40 parts of sucrose in parts by weight. powder, 0.3-0.7 parts of citric acid, 20-30 parts of glucose syrup, 0.3-0.7 parts of essence and 2-4 parts of glycerin.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one is: this embodiment Alihong chewing gum comprises 30 parts of gum base, 2 parts of Alihong, 25 parts of sucrose powder, and 0.2 part of lemon in parts by weight. acid, 20 parts of glucose syrup, 0.1 part of essence and 2 parts of glycerin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com