Reverse osmosis membrane concentrated fruit juice preparation method

A reverse osmosis membrane concentration and fruit juice technology, which is applied in the field of fruit processing, can solve the problems of low concentration, loss of aromatic substances, and cooking taste, etc., and achieve the effect of reducing energy consumption and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

[0018] Implementation example: Xuan papaya juice

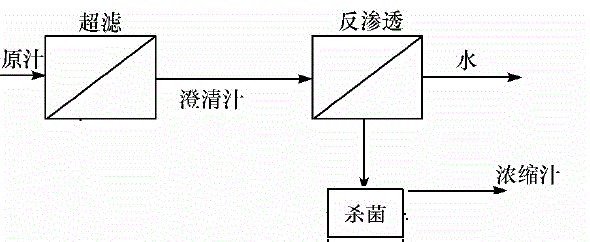

[0019] Select mature Xuan papaya with a mass of 500g, cut it into slices of the same size, then put the sliced Xuan papaya into the extraction pot, add pure water according to different material-to-liquid ratios, heat to 100°C for 30 minutes, and extract After extraction, cool to 45 degrees Celsius, add pectinase, the mass of pectinase is one-thousandth of the mass of the extract, and heat in a water bath to maintain 45 degrees for 2 hours. After enzymatic hydrolysis, use a stainless steel filter to perform coarse filtration to remove precipitated substances. Use a ceramic membrane with a pore size of 0.2 microns to perform ultrafiltration on the filtrate. Take the filtrate after ultrafiltration and introduce it into a reverse osmosis device. Use a reverse osmosis membrane with a cut-off precision of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com