Magnetic field generation device of magnetorheological polishing equipment

A magnetic field generating device and magnetorheological polishing technology, applied in the directions of magnets, magnetic objects, electrical components, etc., can solve the problems of small polishing area, inability to complete complex curved surface polishing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

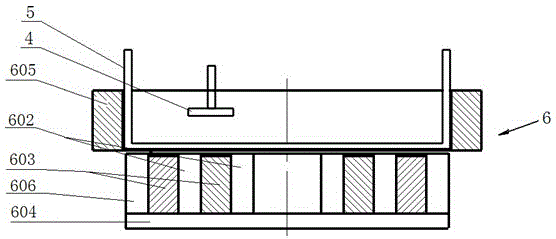

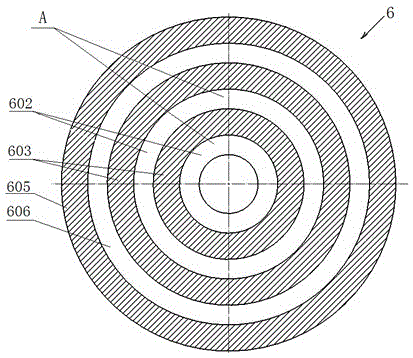

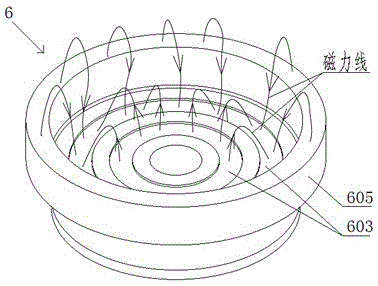

[0018] See figure 1 — image 3 , the magnetic field generating device 6 provided by the present invention is located below the barrel-shaped polishing solution tank 5, and includes two (or more) concentric ring-shaped magnetic poles with opposite polarities of two adjacent magnetic poles, and every two poles The annular magnetic poles with opposite properties form an electromagnetic pole group A, each annular magnetic pole includes an annular magnetic core 602, a magnetic core coil 603 wound on the outer surface of the annular magnetic core 602, the annular magnetic core 602 and the magnetic core coil 603 is fixed on the base plate 604, and a protective ring 606 is provided outside the outermost annular magnetic pole, and an outer coil 605 is arranged on the outer periphery of the polishing solution tank 5, and the lower plane of the outer coil 605 is flush with the upper plane of the annular magnetic pole .

[0019] The energization directions of the magnetic core coil 603 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com