Nanometer zirconium oxide composite ceramic material, tooth color-imitating nanometer zirconium oxide composite ceramic tooth and preparation method thereof

A nano-zirconia and composite ceramic technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of obvious color difference, unsightly teeth, and fracture toughness needs to be further improved, and achieve good ventilation, high simulation, The effect of easy control of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

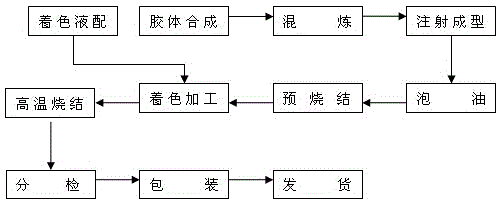

Image

Examples

Embodiment 1

[0029] Nano zirconia composite ceramic material, including the following raw materials in parts by mass: 100 parts of nano zirconia, 10 parts of organic synthetic colloid; wherein, the organic synthetic colloid includes the following raw materials in parts by mass: 25 parts of paraffin wax , 20 parts of polyethylene, 20 parts of polypropylene, 3 parts of stearic acid, 2 parts of oleic acid;

[0030] The preparation method of the nano-zirconia composite ceramic material, the steps are as follows: according to the mass ratio, heating and stirring the organic synthetic colloid until melting, then adding the nano-zirconia, and mixing in a mixer for 150 minutes, Then heat up to 50°C and continue mixing until the particle size of the material is not greater than 3mm; wherein the preparation method of the organic synthetic colloid is: according to the mass ratio, the paraffin wax is heated to 200°C, and polyethylene is added after the paraffin wax is completely melted. Add polypropyl...

Embodiment 2

[0041] Nano zirconia composite ceramic material, including the following raw materials in parts by mass: 90 parts of nano zirconia, 80 parts of organic synthetic colloid; wherein, the organic synthetic colloid includes the following raw materials in parts by mass: 10 parts of paraffin wax , 10 parts of polyethylene, 10 parts of polypropylene, 1 part of stearic acid, and 1 part of oleic acid; the preparation method of the nano-zirconia composite ceramic material, the steps are as follows: according to the mass ratio, the organic synthetic colloid Heat and stir until melting, then add the nano-zirconia, and mix in a mixer for 100 minutes, then raise the temperature to 45°C and continue mixing until the particle size of the material is not greater than 3mm; the preparation method of the organic synthetic colloid is as follows: Mass proportioning, heat up the paraffin wax to 200°C, add polyethylene after the paraffin wax is completely melted, add polypropylene after the polyethylen...

Embodiment 3

[0052] Nano zirconia composite ceramic material, including the following raw materials in parts by mass: 100 parts of nano zirconia, 80 parts of organic synthetic colloid; wherein, the organic synthetic colloid includes the following raw materials in parts by mass: 50 parts of paraffin wax , 30 parts of polyethylene, 30 parts of polypropylene, 5 parts of stearic acid, and 5 parts of oleic acid; the preparation method of the nano-zirconia composite ceramic material, the steps are as follows: according to the mass ratio, the organic synthetic colloid Heat and stir until melting, then add the nano-zirconia, and mix in a mixer for 200 minutes, then raise the temperature to 55°C and continue mixing until the particle size of the material is not greater than 3mm; the preparation method of the organic synthetic colloid is as follows: Mass proportioning, heat up the paraffin wax to 205°C, add polyethylene after the paraffin wax is completely melted, add polypropylene after the polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com