Titanium alloy used for foldable bicycle frame and preparation method of titanium alloy

A technology of folding bicycles and titanium alloys, applied in the field of titanium alloys, can solve the problems that the comprehensive performance of alloy materials needs to be strengthened, and achieve the effects of strong noise reduction and shock absorption, good comprehensive performance and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

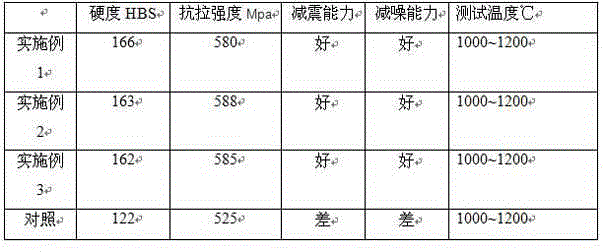

Examples

Embodiment 1

[0018] A titanium alloy for a foldable bicycle frame, the main elements of the titanium alloy are: 0.2-4.0% of zirconium element, 0.5-1.2% of magnesium element, 2-3% of iron element, 0.3-0.5% of silicon element, Manganese element 0.2~0.5%, aluminum element 0.2~0.3%, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus element≤0.1%, sulfur element≤0.1%, selenium element≤0.1%.

[0019] The main elements of titanium alloy are: 2.1% zirconium, 0.8% magnesium, 2.5% iron, 0.4% silicon, 0.35% manganese, 0.25% aluminum, and the balance is titanium and unavoidable impurities.

[0020] A method for preparing a titanium alloy for a foldable bicycle frame, comprising the following steps:

[0021] 1) Weigh titanium alloy, aluminum-silicon alloy, and magnesium-zirconium alloy as raw materials according to weight percentage, add them to the melting furnace and heat at 850~900°C to melt all the materials in the melting furnace. ...

Embodiment 2

[0029] A titanium alloy for a foldable bicycle frame, the main elements of the titanium alloy are: 0.2% zirconium element, 0.5% magnesium element, 2% iron element, 0.3% silicon element, 0.2% manganese element, 0.2% aluminum element %, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus 0.1%, sulfur 0.1%, selenium 0.1%.

[0030] A method for preparing a titanium alloy for a foldable bicycle frame, comprising the following steps:

[0031] 1) Weigh titanium alloy, aluminum-silicon alloy, and magnesium-zirconium alloy as raw materials according to weight percentage, add them to the melting furnace and heat them at 850°C to melt all the materials in the melting furnace. The melting time is 8 hours, and add phosphorus removal agent and desulfurization agent at the same time Remove sulfur and phosphorus elements;

[0032] 2) Pass N into the melting furnace 2 -Cl 2 The mixed gas was refined for 6 minutes at a temper...

Embodiment 3

[0039] A titanium alloy for a foldable bicycle frame, the main elements of the titanium alloy are: 4.0% zirconium, 1.2% magnesium, 3% iron, 0.5% silicon, 0.5% manganese, and 0.3% aluminum %, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus 0.03%, sulfur 0.02%, selenium 0.01%.

[0040] A method for preparing a titanium alloy for a foldable bicycle frame, comprising the following steps:

[0041] 1) Weigh titanium alloy, aluminum-silicon alloy, and magnesium-zirconium alloy as raw materials according to weight percentage, add them to the melting furnace and heat at 900°C to melt all the materials in the melting furnace. The melting time is 6 hours, and add phosphorus removal agent and desulfurization agent at the same time Remove sulfur and phosphorus elements;

[0042] 2) Feed N into the melting furnace 2 -Cl 2 The mixed gas is refined for 5 minutes at a temperature of 900°C to obtain a melt;

[0043] 3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com