Q&P steel compounded with vanadium and titanium and manufacturing method thereof

A technology of composite addition and manufacturing method, which is applied in the field of Q&P steel with titanium composite addition and its manufacture, and vanadium, which can solve the problems of difficult control of quenching temperature, etc., and achieve the effects of low production cost, excellent strength and toughness matching, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, as shown in Table 1 below.

[0030] Table 1 Slab composition (wt.%)

[0031]

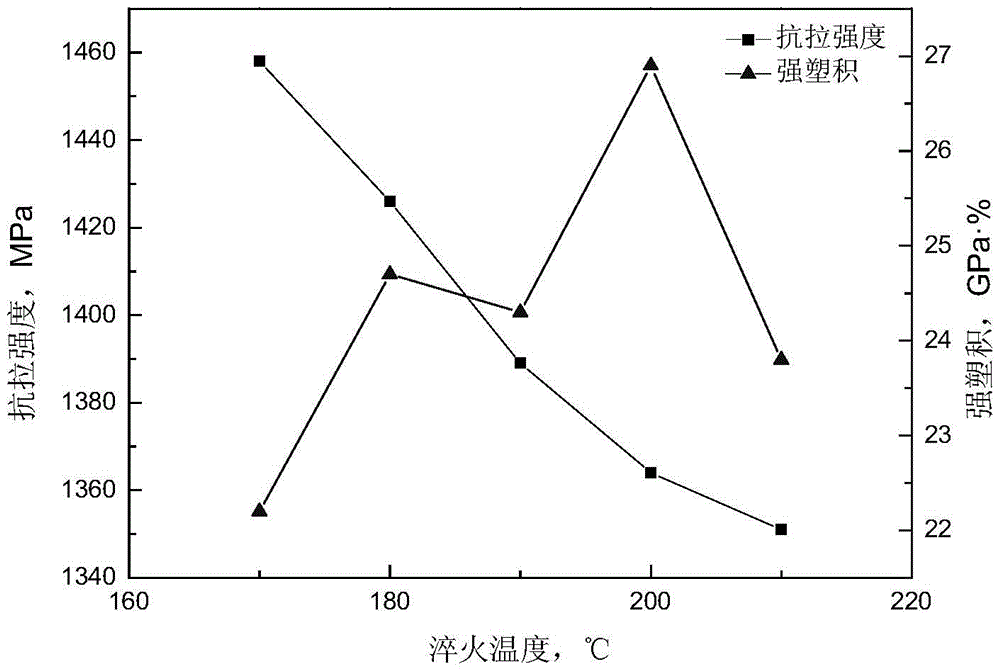

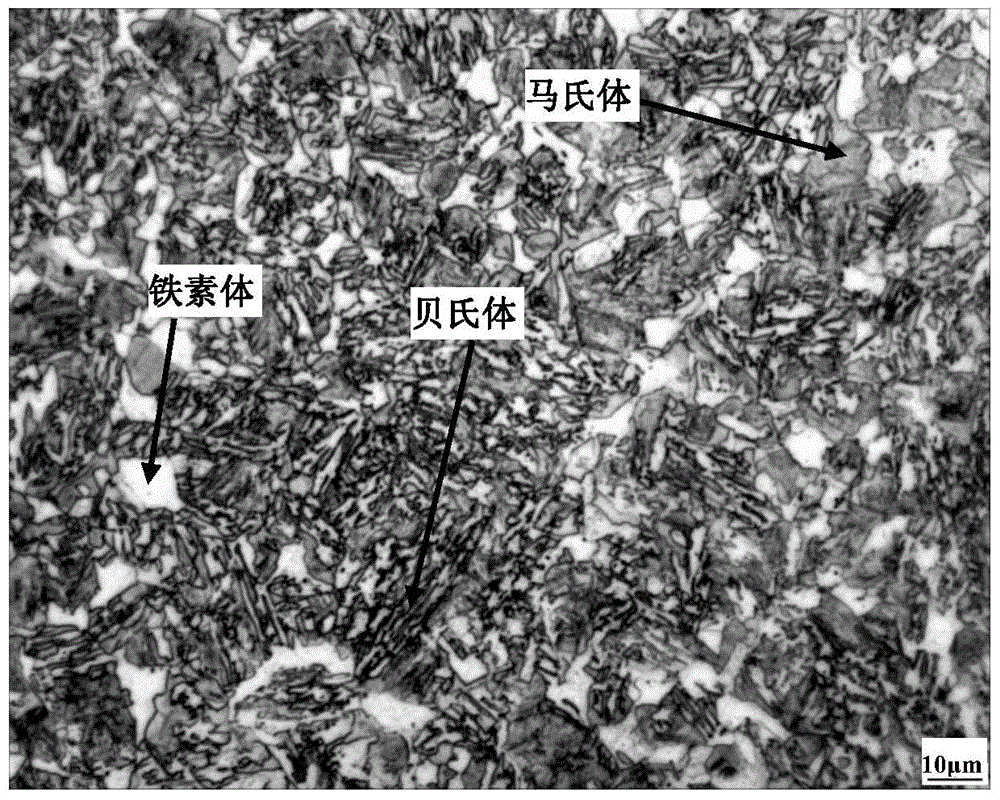

[0032] The hot rolling adopts the following process: heat the prepared slab from room temperature to 1200°C, keep it warm for 2 hours, start rolling at 1150°C, and finish hot rolling at 900°C. When the billet is air-cooled to 800°C, water cooling starts, the cooling rate is 20°C / s, and coiling starts when the billet is cooled to below 190°C. At this time, the structure of the hot-rolled sheet is ferrite + martensite + bainite, see figure 2 , The thickness of the hot-rolled plate is 3.6mm. The cold-rolling process is as follows: the hot-rolled plate is pickled and then cold-rolled, the cold-rolled reduction rate is 58%, and the thickness of the cold-rolled plate is 1.5mm. The following three examples are taken for different distribution tempe...

Embodiment 2

[0038] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, see Table 3 below.

[0039] Table 3 Slab composition (wt.%)

[0040]

[0041] The hot rolling adopts the following process: heating the prepared slab from room temperature to 1170°C, holding it for 1.7 hours, starting the rolling temperature at 1150°C, and finishing the hot rolling at 920°C; When the billet is air-cooled to 820°C, water cooling starts, the cooling rate is 25°C / s, and coiling starts when the billet is cooled to below 190°C. At this time, the structure of the hot-rolled sheet is ferrite + martensite + bainite, see figure 2 , The thickness of the hot-rolled plate is 3.5mm. The cold-rolling process is as follows: the hot-rolled plate is pickled and then cold-rolled, the cold-rolled reduction rate is 70%, and the thickness of the cold-rolled plate is 2.45mm. The following three examples are taken for differ...

Embodiment 3

[0047] First, smelting and continuous casting are carried out according to the above composition range, and then the composition of the slab is detected, see Table 5 below.

[0048] Table 5 Slab Composition (wt.%)

[0049]

[0050] The hot rolling adopts the following process: heat the prepared slab from room temperature to 1220°C, keep it warm for 1.5 hours, start rolling at 1150°C, and finish hot rolling at 890°C. When the billet is air-cooled to 780°C, water cooling starts, the cooling rate is 15°C / s, and coiling starts when the billet is cooled to below 190°C. At this time, the structure of the hot-rolled sheet is ferrite + martensite + bainite, see figure 2 , The thickness of the hot-rolled plate is 4.5mm. The cold-rolling process is as follows: the hot-rolled plate is pickled and then cold-rolled, the cold-rolled reduction rate is 50%, and the thickness of the cold-rolled plate is 2.1mm. The following three examples are taken for different distribution temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com