Building insulation precast block and modular reinforcement cast-in-place construction method thereof

A technology for building thermal insulation and prefabricated blocks, which is applied to buildings, building components, building materials, etc., can solve the problems of difficult quality assurance, high cost, and few building energy-saving modular technology products, and achieve the effect of saving new materials and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

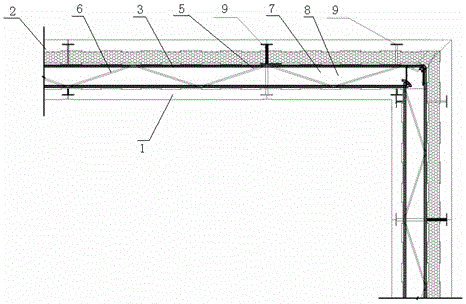

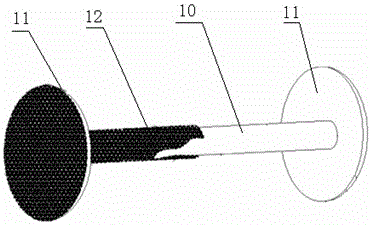

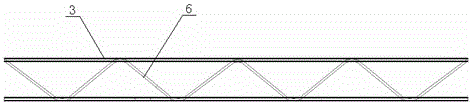

[0051] Example 1: Reference Figure 1-8 . The building thermal insulation prefabricated block includes a plurality of spliced prefabricated block bodies. The prefabricated block body includes an inner panel 1 and an outer panel 2. A net-like three-dimensional frame runs through the inner panel 1 and the outer panel 2. The net-like three-dimensional frame includes mutual Interspersed a plurality of horizontal reinforcement frames 18, vertical reinforcement frames 19, the horizontal reinforcement frames 18 and the vertical reinforcement frames 19 have the same structure, both include two parallel main bars 3, between the two main bars 3 are provided along the two The obliquely supported abdominal ribs 5 arranged in a zigzag shape in the length direction, the obliquely supported abdominal ribs 5 include a plurality of oblique ribs 6 connected end to end in sequence, the two ends of the oblique ribs 6 are welded to the main ribs 3, and the inner plate 1 and the outer plate 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com