An accumulator-driven sliding sleeve switch for petroleum well completion

A sliding sleeve switch and accumulator technology, applied in wellbore/well components, wellbore/well valve device, earthwork drilling, etc., can solve the problem of unfavorable oil reservoir development, many overall pipelines, and difficult operation in horizontal sections and other problems, to avoid long-distance transmission and excessively long pipelines, the overall structure is simple, and the operation time is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

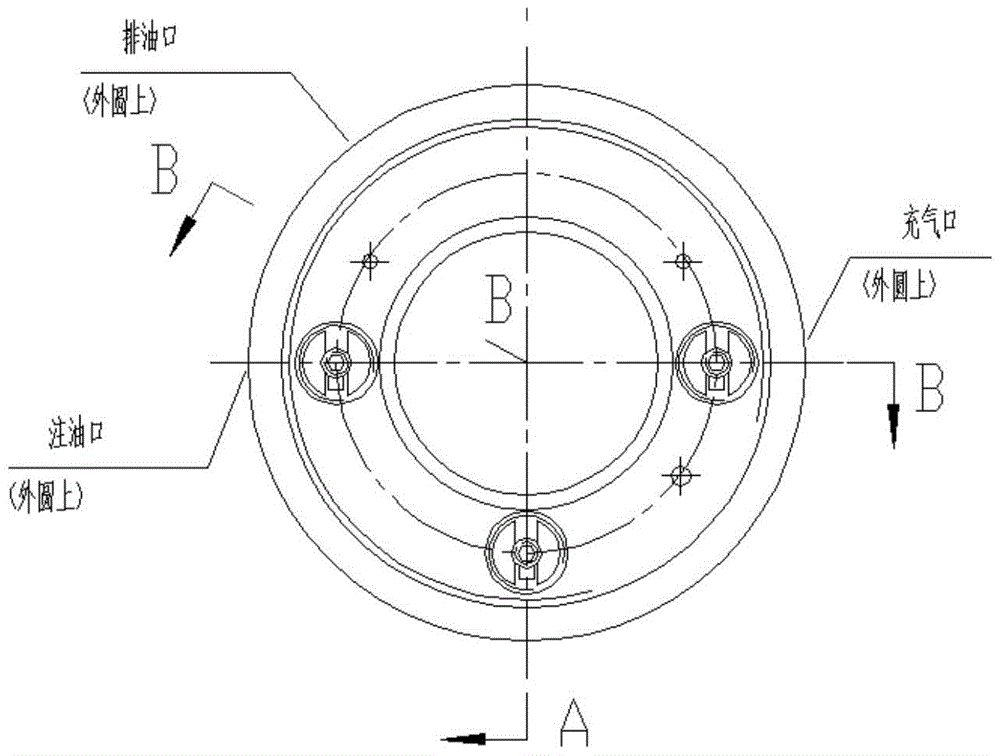

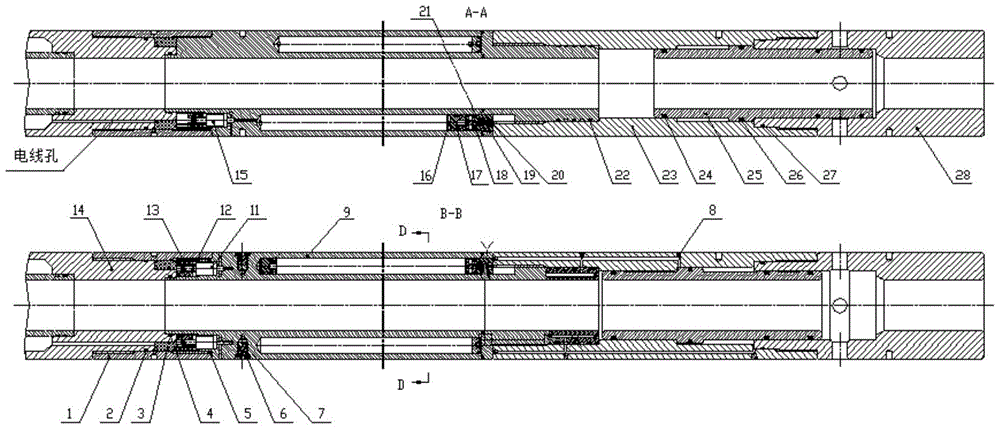

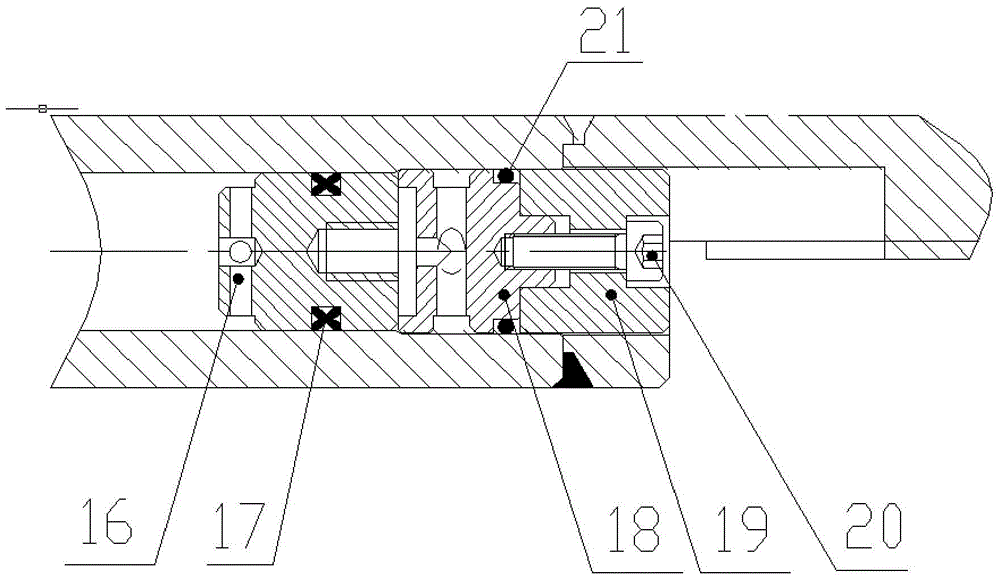

[0018] Such as Figure 1-4 As shown, the present invention is an accumulator-driven sliding sleeve switch for petroleum well completion. The sliding sleeve switch is a cylindrical structure, and the intermediate annular space is an oil channel hole, including an electrical control part, a power source part and an action execution part. .

[0019] The electrical control part is installed on the front end of the sliding sleeve switch, including connecting screw sleeve 1, first O-ring 2, three conductive slip rings 3, second O-ring 4, third O-ring 5, inner hexagon plug 6. Two one-way valves 7, porous joint weldment 9, two two-position three-way electromagnetic cartridge valves 11, three set screws 12, three valve plugs 13, signal pup end 14 and two-position two-way through the electromagnetic cartridge valve 15; the connecting screw sleeve 1 is threadedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com