Base rock uplift region shielding tool-changing in-situ reinforcement method

A technology of shield and bedrock, which is applied in the field of in-situ reinforcement of shield machine tool change in bedrock uplift areas, can solve the problems of inability to implement, unfeasible to open warehouses at atmospheric pressure, and large leakage of compressed air, so as to ensure effectiveness. , avoid the construction progress, prevent the effect of slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] In order to solve the problem that in-situ soil reinforcement is difficult during shield tunnel construction in existing reclamation areas, the present invention provides an in-situ reinforcement method for shield tunneling tool change in bedrock uplift areas, which includes the following steps:

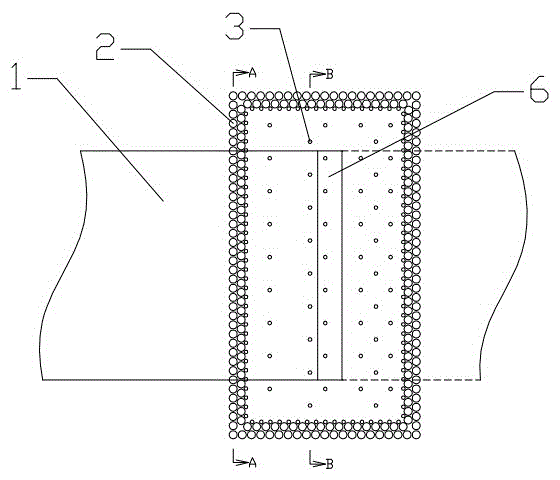

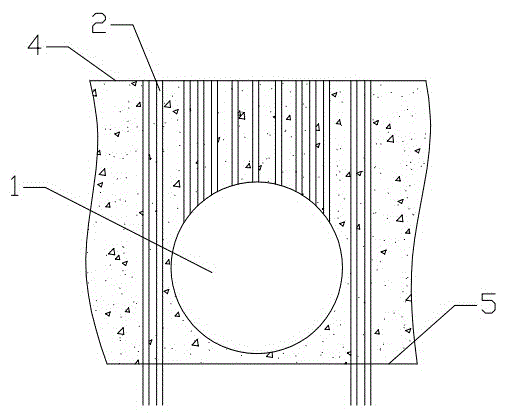

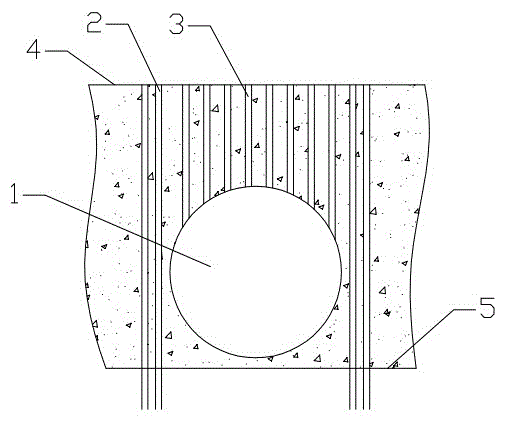

[0028] The first step: the construction of the micro pile isolation area, use the micro piles around the cutter head of the shield machine to form a rectangular isolation area, and the micro piles 2 in the rectangular isolation area are respectively located in front, rear, left and right sides of the shield machine cutter head 6, The micro-piles 2 in the front are 2-3 meters away from the shield machine cutterhead, the rear micro-piles 2 are 3-4 meters away from the shield machine cutterhead, and the micro-piles 2 on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com