Anti-seepage device above butterfly valve rotary shaft

A rotating shaft, anti-leakage technology, used in valve devices, lift valves, engine components, etc., can solve problems such as inability to achieve complete sealing, achieve the effects of easy introduction, good chemical stability, and reduce the possibility of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

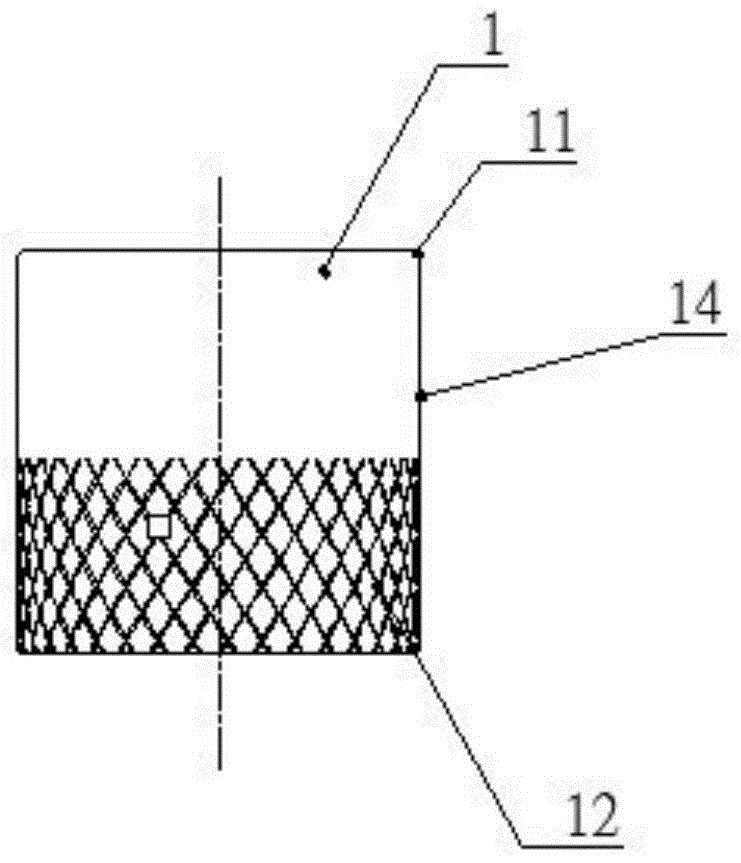

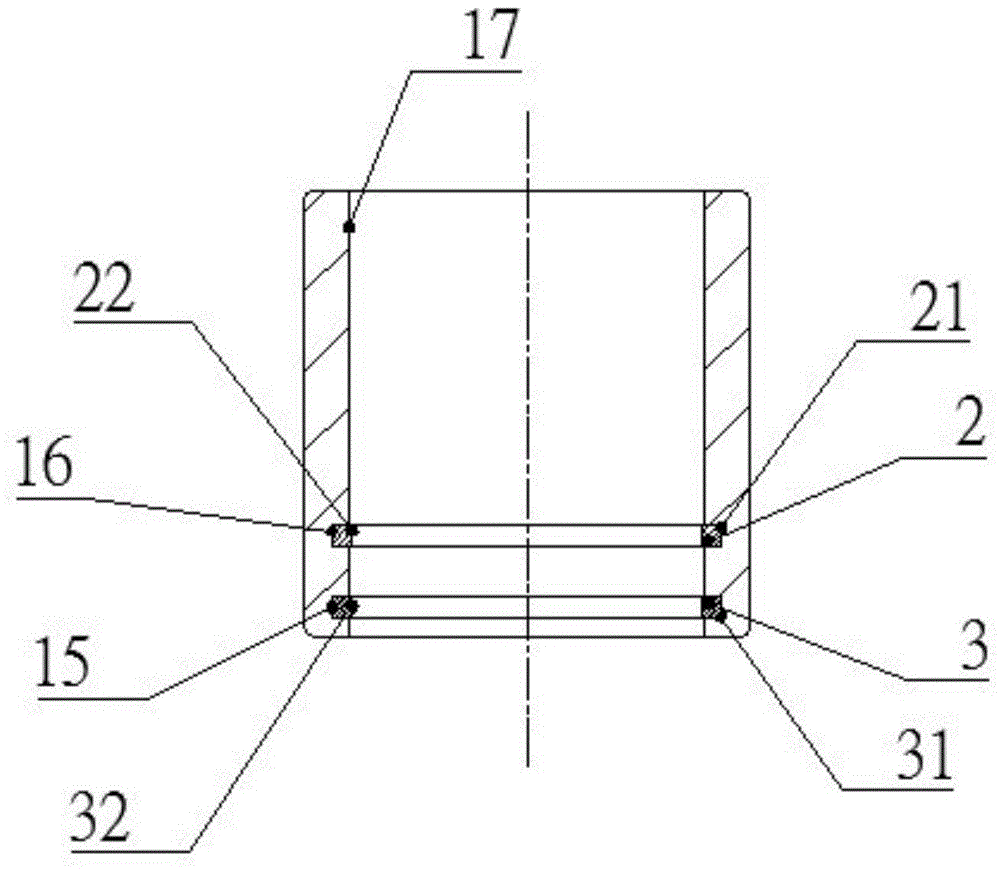

[0009] Such as figure 1 As shown, the present invention is an anti-leakage device above the rotating shaft of a butterfly valve, including a round tube 1, an O-ring 2 and a sealing ring 3. The overall material of the round tube 1 is brass, which has stable chemical properties and is not easily corroded. The outside of the round pipe 1 includes rounded corners 11 at both ends. The rounded corners here belong to passivation treatment, which facilitates the introduction of the round pipe during the assembly process with the butterfly valve body, and also reduces the injury rate of the operator to a certain extent. The round pipe 1 It also includes the outer knurled pattern 12, which increases the friction coefficient during the interference fit between the round tube 1 and the valve body. After the assembly is completed, it is more conducive to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com