Device for treating and recycling exhaust gas of boiler

A boiler exhaust gas and spraying device technology, which is applied in the direction of feed water heater, preheating, steam generation, etc., can solve the problems of poor smoke and dust removal effect, affecting food processing quality, limited funds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

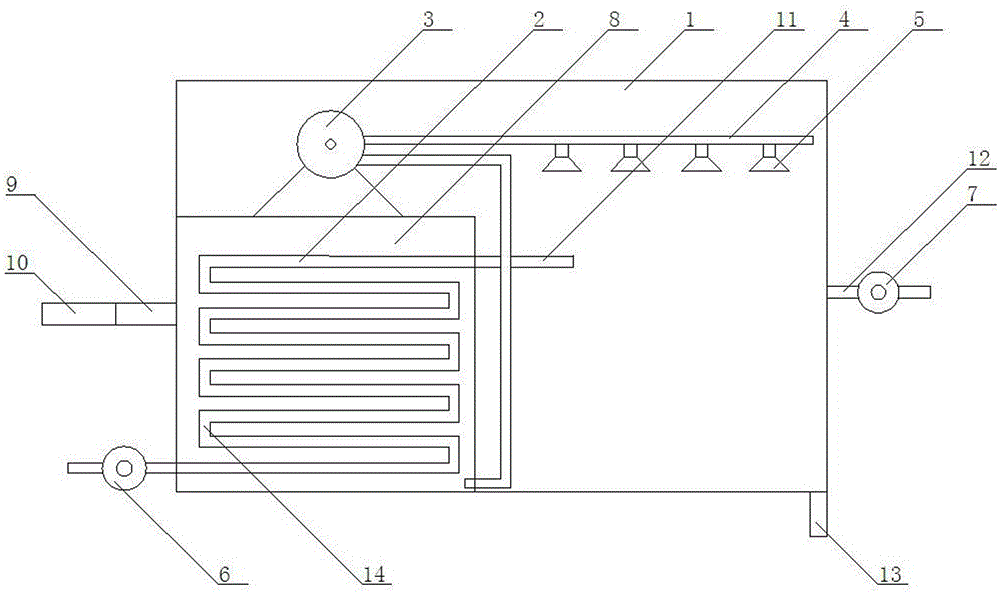

[0015] A boiler exhaust gas treatment and reuse device, including a box body 1, a curved air pipe 2, a water pump 3, a straight water pipe 4, a spray device 5, a first suction fan 6, a second suction fan 7, and a water tank 8. A water inlet pipe 9 is installed in the middle of the left end of the box body 1, and a curved air pipe 2 is installed at the lower left end of the box body 1. The left end of the curved air pipe 2 is connected to the first suction fan 6, and the left end of the first suction fan 6 passes through the pipeline. 9 Connect the boiler exhaust gas discharge port 10, the lower left end of the box body 1 is equipped with a water tank 8, the curved air pipe 2 is installed inside the water tank 8, and the nozzle 11 at one end of the curved air pipe 2 passes through the right side of the water tank 8 On the surface, the bottom end of the right side of the water tank 8 is connected to the water pump 3 at the upper end of the water tank 8 through the curved water pi...

Embodiment 2

[0017] A boiler exhaust gas treatment and reuse device, the curved air pipe 2 has eight bends 14 .

Embodiment 3

[0019] A boiler waste gas treatment and reuse device. Boiler waste gas enters the curved air pipe 2 to heat the water inside the water tank 8. After heating, it is discharged to the inside of the tank 1. The water inside the water tank 8 is sucked out by the water pump 3 to become the spray device 5. Water supply, the spray device 5 sprays the heated water to purify the boiler exhaust gas, the purified exhaust gas is discharged through the exhaust pipe 12, and the heated water sprayed by the spray device 6 flows into the boiler through the water outlet pipe 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com