Method of using ammonium oxalate to prepare biosorbent for treating salt-based block green dye wastewater

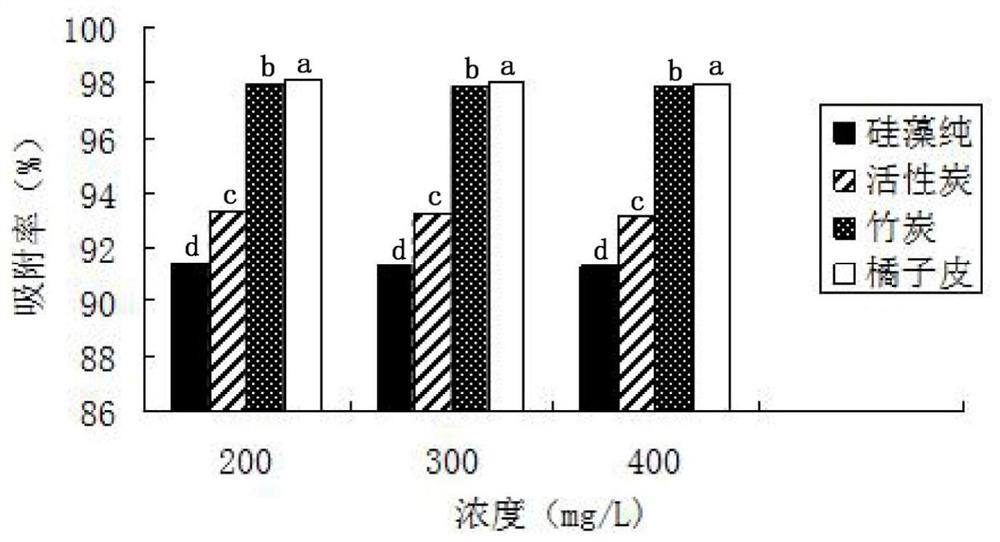

A biosorbent, salt-based block green technology, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor removal effect and secondary pollution, and achieve economic circular development and protection. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

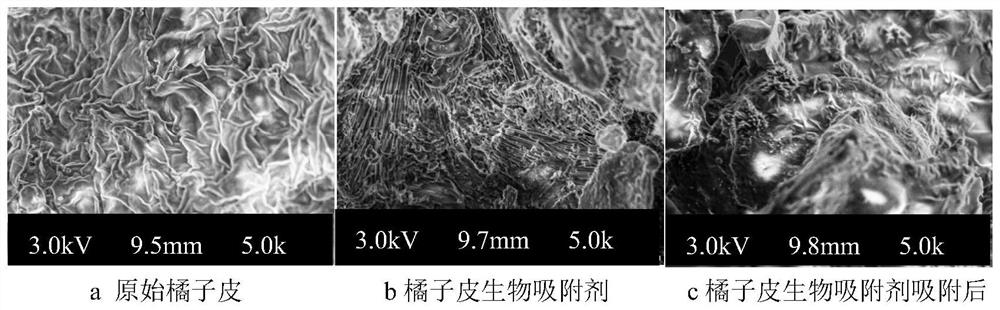

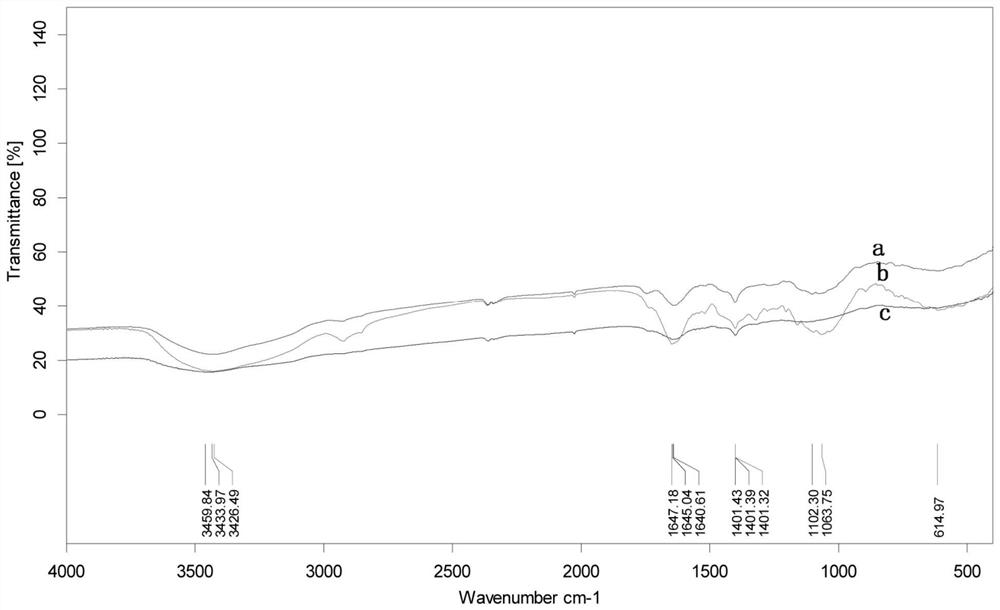

[0025] A method of using ammonium oxalate to prepare a biosorbent for treating salt-based block green dye wastewater in this embodiment, the specific steps are as follows:

[0026] 1) Washing: Collect waste orange peels from food factories as materials and rinse them clean;

[0027] 2) Drying: place the washed orange peel in a constant temperature drying oven at 60°C and 6.67×102Pa to dry to constant weight;

[0028] 3) Cutting: Cut the dried orange peel into 3-5cm long pieces;

[0029] 4) Cooking: Put the orange peel pieces in boiling water at 100°C and boil for 40 minutes;

[0030] 5) Soaking in ammonium oxalate: cool the cooked orange peel to room temperature, soak in ammonium oxalate solution with a concentration of 1%, and place in a constant temperature water bath at 25°C for 50 minutes;

[0031] 6) Alkali soaking: soak the washed orange peel pieces in a sodium hydroxide solution with a pH of 12 for 50 minutes;

Embodiment 2

[0047] A method of using ammonium oxalate to prepare a biosorbent for treating salt-based block green dye wastewater in this embodiment, the specific steps are as follows:

[0048] 1) Washing: Collect waste orange peels from food factories as materials and rinse them clean;

[0049] 2) Drying: place the washed orange peel in a constant temperature drying oven at 70°C and 6.67×102Pa to dry to constant weight;

[0050] 3) Cutting: Cut the dried orange peel into 3-5cm long pieces;

[0051] 4) Cooking: put the orange peel pieces in boiling water at 100°C and boil for 60 minutes;

[0052] 5) Soaking in ammonium oxalate: cool the cooked orange peels to room temperature, soak them in ammonium oxalate solution with a concentration of 2.5%, and place them in a constant temperature water bath at 20°C for 60 minutes;

[0053] 6) Alkali soaking: soak the washed orange peel pieces in a sodium hydroxide solution with a pH of 13 for 20 minutes;

Embodiment 3

[0087] A method of using ammonium oxalate to prepare a biosorbent for treating salt-based block green dye wastewater in this embodiment, the specific steps are as follows:

[0088] 1) Washing: Collect waste orange peels from food factories as materials and rinse them clean;

[0089] 2) Drying: place the washed orange peel in a constant temperature drying oven at 65°C and 6.67×102Pa to dry to constant weight;

[0090] 3) Cutting: Cut the dried orange peel into 3-5cm long pieces;

[0091] 4) Cooking: Put the orange peel pieces in boiling water at 100°C and boil for 50 minutes;

[0092] 5) Soaking in ammonium oxalate: cool the cooked orange peels to room temperature, soak them in a 0.5% ammonium oxalate solution, and place them in a constant temperature water bath at 60°C for 20 minutes;

[0093] 6) Alkaline soaking: soak the washed orange peel pieces in a sodium hydroxide solution with a pH of 11 for 60 minutes;

[0094] 7) Hydrogen peroxide soaking: fully rinse with distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com