A Method for Helicopter Blade Mass Unbalance Detection Based on Fiber Bragg Grating Vibration Sensing System

A technology of vibration sensing system and mass imbalance, applied in static/dynamic balance test, machine/structural component test, measuring device, etc., can solve the structural hazard of helicopter body, the long time to lock the target for the first time, and the inability to quantify Analysis and other issues to achieve the effect of high success rate, avoid subjectivity, and objective data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

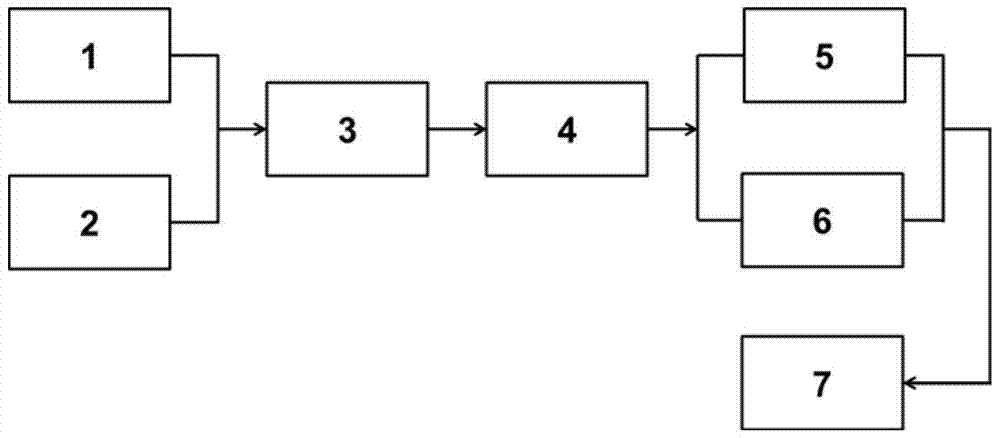

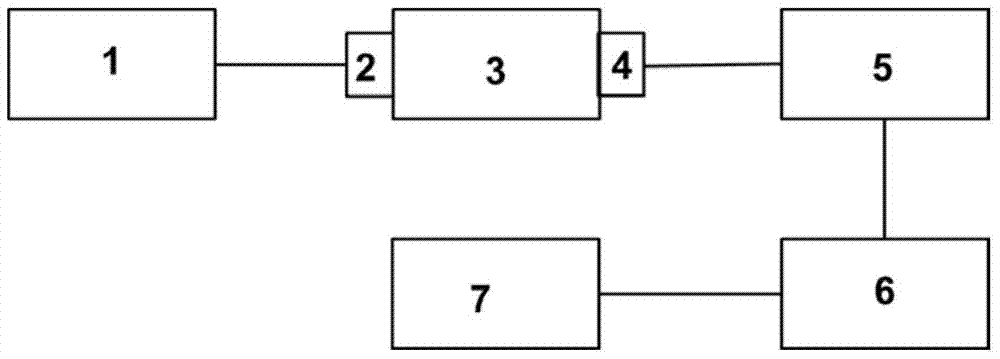

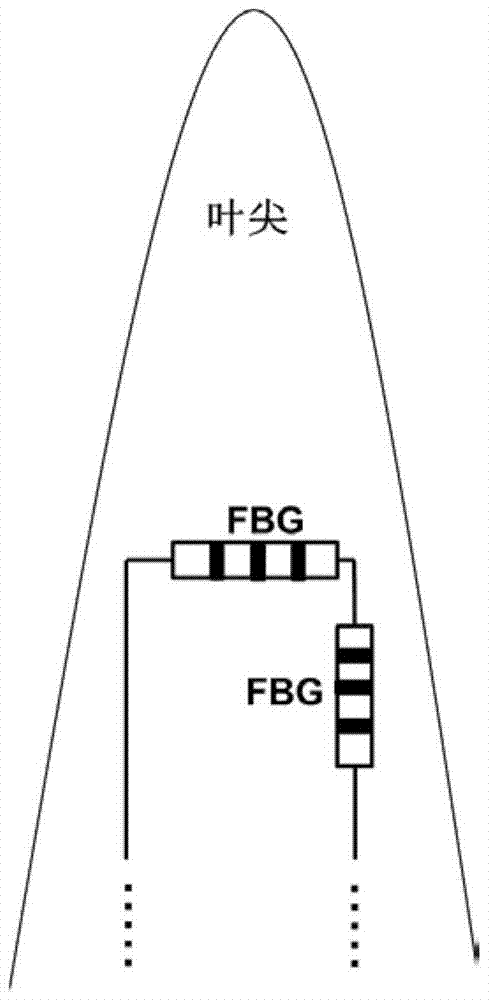

[0015] figure 1 It is the overall idea and detection flow chart of this patent, 1 is to paste the fiber grating sensor on the surface of the helicopter blade, 2 is to paste the fiber grating sensor on the surface of the blade base, 3 is to start the detection when the helicopter is driving a large vehicle, and 4 is to Select an appropriate sampling frequency to record data, 5 is to analyze the collected raw data in time domain, including calculating the peak value, peak factor, kurtosis coefficient, root mean square value and other parameters, 6 is to analyze the collected data Frequency domain analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com