Semiconductor laser temperature simulation method based on TEC temperature control

A simulation method and laser technology, applied in the field of optical communication, can solve problems affecting output optical power and wavelength, temperature rise, heat accumulation, etc., and achieve the effect of speeding up the simulation progress and improving the simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

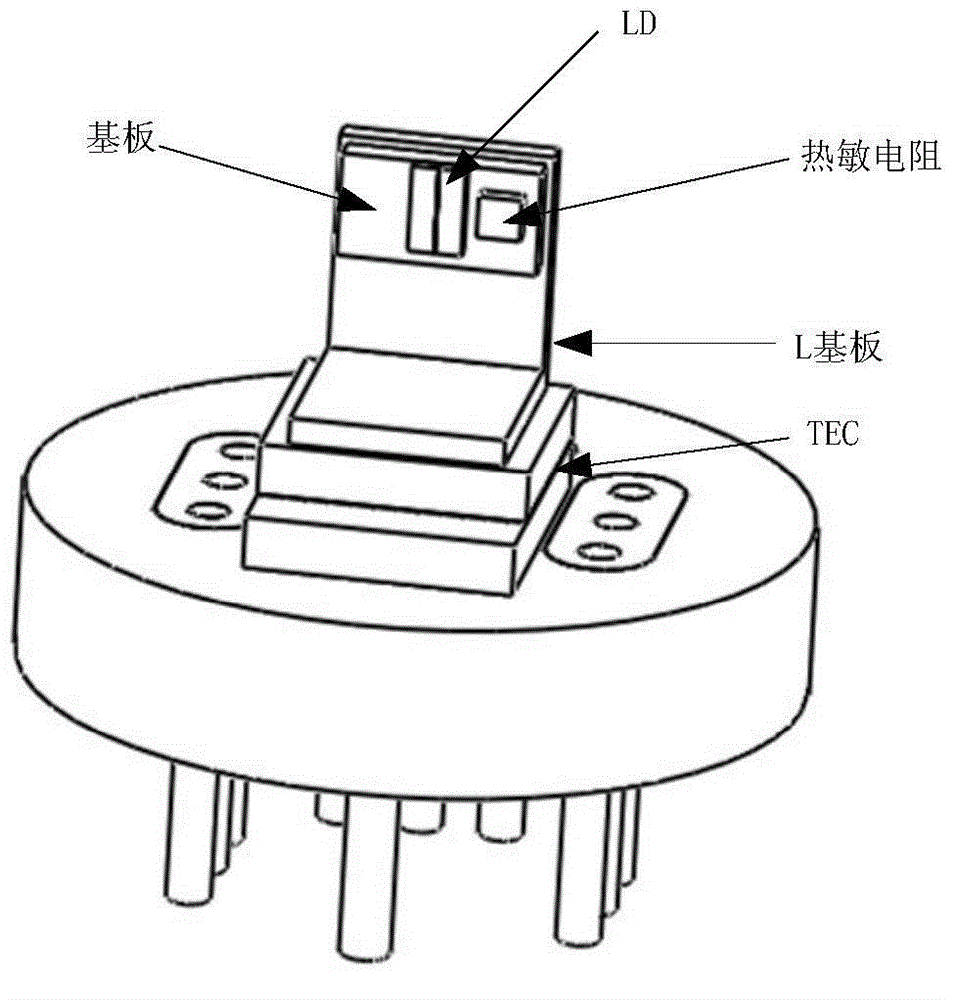

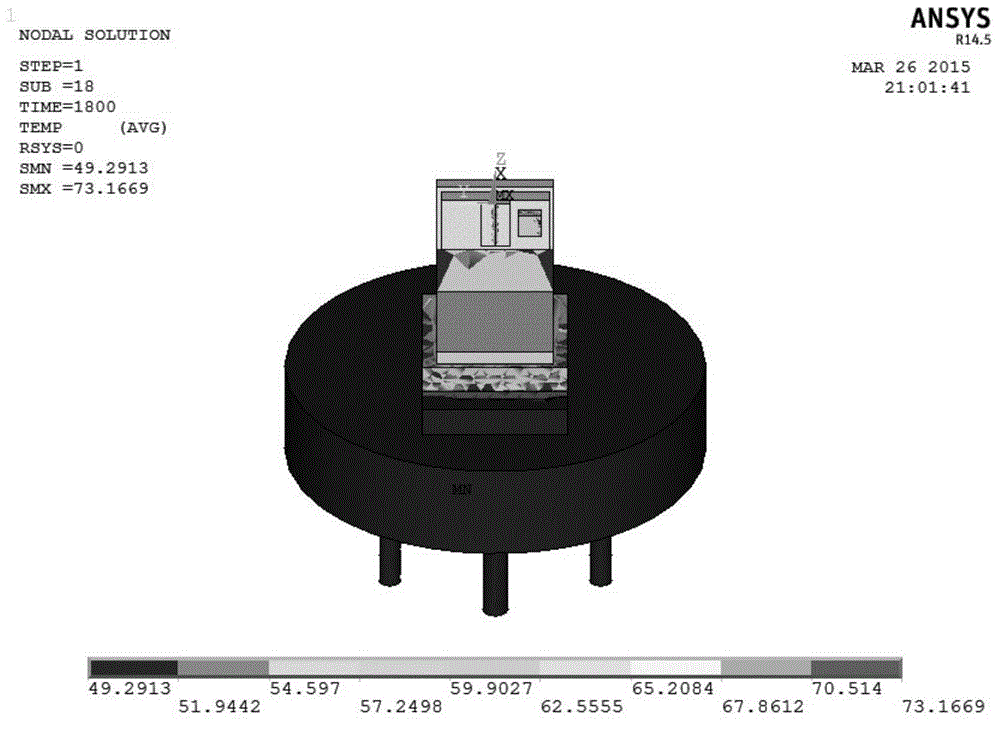

[0039] A temperature simulation method for semiconductor lasers based on TEC temperature control. Thermal analysis software ANSYS is used to simulate the temperature field of semiconductor lasers. By dynamically controlling the heating or cooling state of TEC, the constant temperature control of TO-CAN package TOSA is realized. The simulated The thermal characteristics of semiconductor lasers under actual working conditions; including the following steps:

[0040] (1) define cell type: utilize the thermal analysis unit SOLID279 of thermal analysis software ANSYS, set the material property of each part of semiconductor laser: comprise thermal conductivity, density and specific heat capacity; Load the 3D model of described semiconductor laser, and the described The 3D model is divided into grids; the thermal analysis software ANSYS is used to manually pick up the adjacent grids sequentially;

[0041] (2) Set the thermal analysis type of ANSYS as transient analysis; define the in...

Embodiment 2

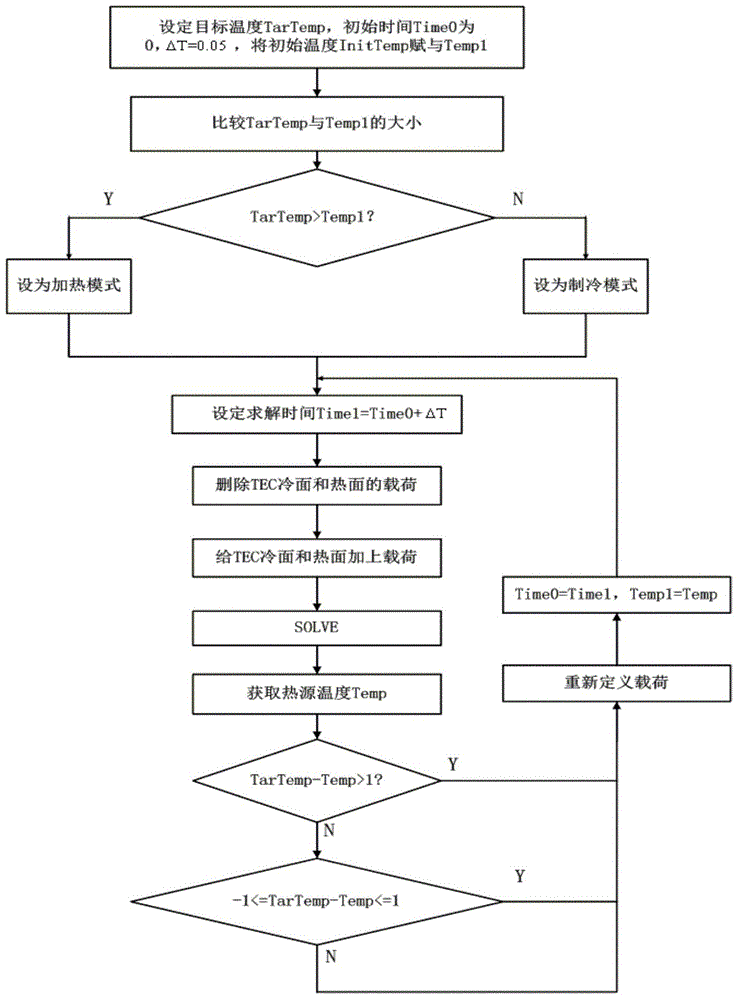

[0045] A kind of temperature simulation method based on the semiconductor laser of TEC temperature control as described in embodiment 1, its difference is that, the step of described dynamic control TEC working state is as follows:

[0046] (2-1) Set an initial temperature InitTemp, a target temperature TarTemp, and a power P of the semiconductor laser; the initial temperature InitTemp is 10°C, and the target temperature TarTemp is 25°C;

[0047] (2-2) Set the initial time Time0, the analysis step size ΔT; the initial time Time0 is 0, and the ΔT is 0.05s;

[0048] (2-3) Compare the initial temperature InitTemp with the target temperature TarTemp:

[0049] If InitTemp is higher than TarTemp, the working state of the TEC is cooling mode;

[0050] If InitTemp is lower than TarTemp, the working state of the TEC is heating mode;

[0051] (2-4) According to step (2-3), the thermal load Kac is set to the cold surface of the TEC, the thermal load Kah is set on the hot surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com