High-strength hot-dip galvanized steel sheet and process for manufacturing same

A technology of hot dip galvanizing and manufacturing method, applied in manufacturing tools, chemical instruments and methods, hot dip plating process, etc., can solve problems such as inability to obtain effects stably, and achieve excellent fatigue resistance characteristics and excellent coating adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

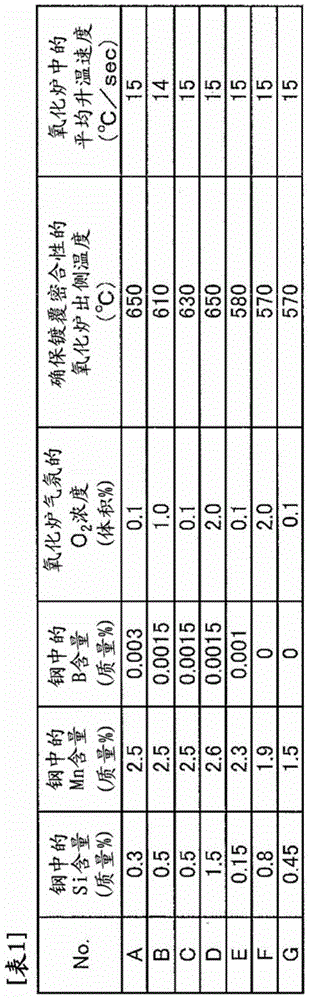

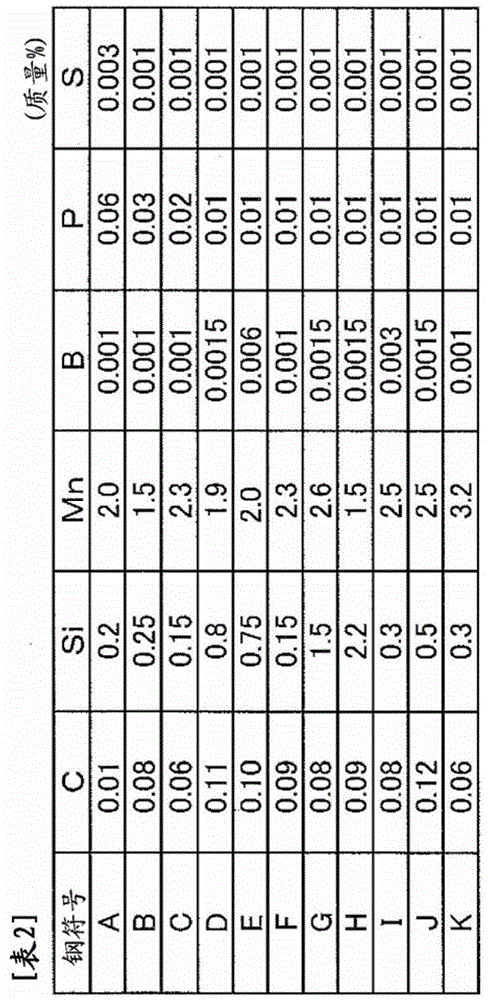

[0086] The cast slabs obtained by melting the steels having the chemical components shown in Table 2 were hot-rolled, pickled, and then cold-rolled to produce cold-rolled steel sheets with a thickness of 1.2 mm.

[0087] [Table 2]

[0088]

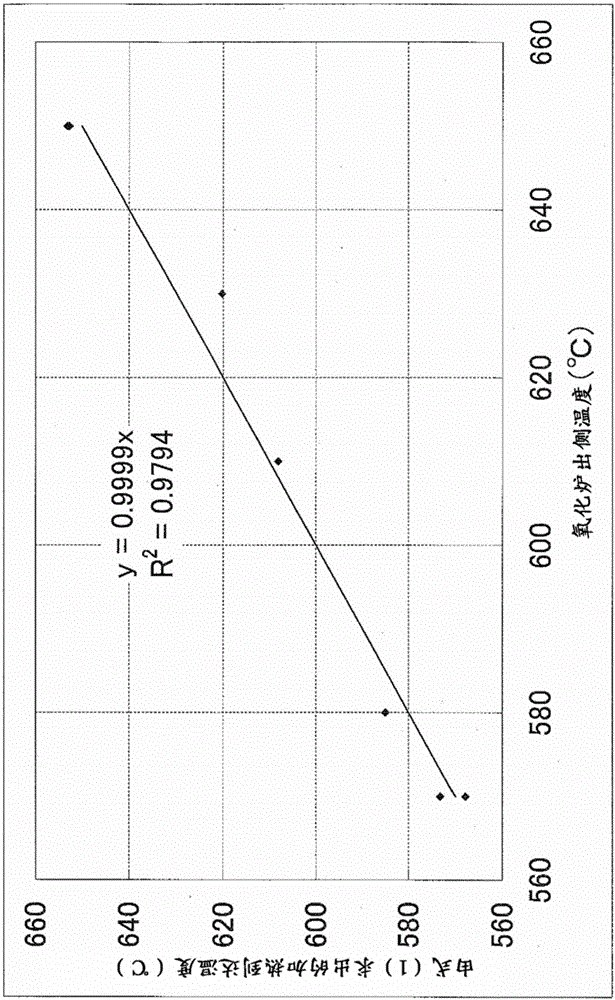

[0089] Thereafter, the cold-rolled steel sheet was heated and oxidized by appropriately changing the outlet temperature of the oxidation furnace in a CGL having a DFF type oxidation furnace. The direct fire burner uses COG in the fuel and adjusts the air ratio to adjust the oxygen concentration of the atmosphere. The temperature of the steel plate on the exit side of the oxidation furnace was measured with a radiation thermometer. Next, reduction annealing was performed at 850°C for 20s in the reduction zone, hot-coating was performed in a galvanizing bath at 460°C with the Al addition adjusted to 0.19%, and the mass per unit area was adjusted to about 50g by gas scraping. / m 2 .

[0090] The thus obtained hot-dip galvanized steel s...

Embodiment 2

[0109] The cast slabs obtained by melting the steels having the chemical components shown in Table 2 were hot-rolled, pickled, and then cold-rolled to produce cold-rolled steel sheets with a thickness of 1.2 mm.

[0110] Thereafter, oxidation treatment and reduction annealing were performed in the same manner as in Example 1. Furthermore, hot-dip coating was performed in a 460°C galvanizing bath with an Al addition adjusted to 0.13%, and the mass per unit area was adjusted to about 50 g / m by gas scraping. 2 , alloying treatment was carried out at the specified temperature shown in Table 4 for 20 to 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com