Inductive load driver slew rate controller

A conversion rate and rate control technology, applied in electronic switches, electrical components, pulse technology, etc., can solve problems such as low system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

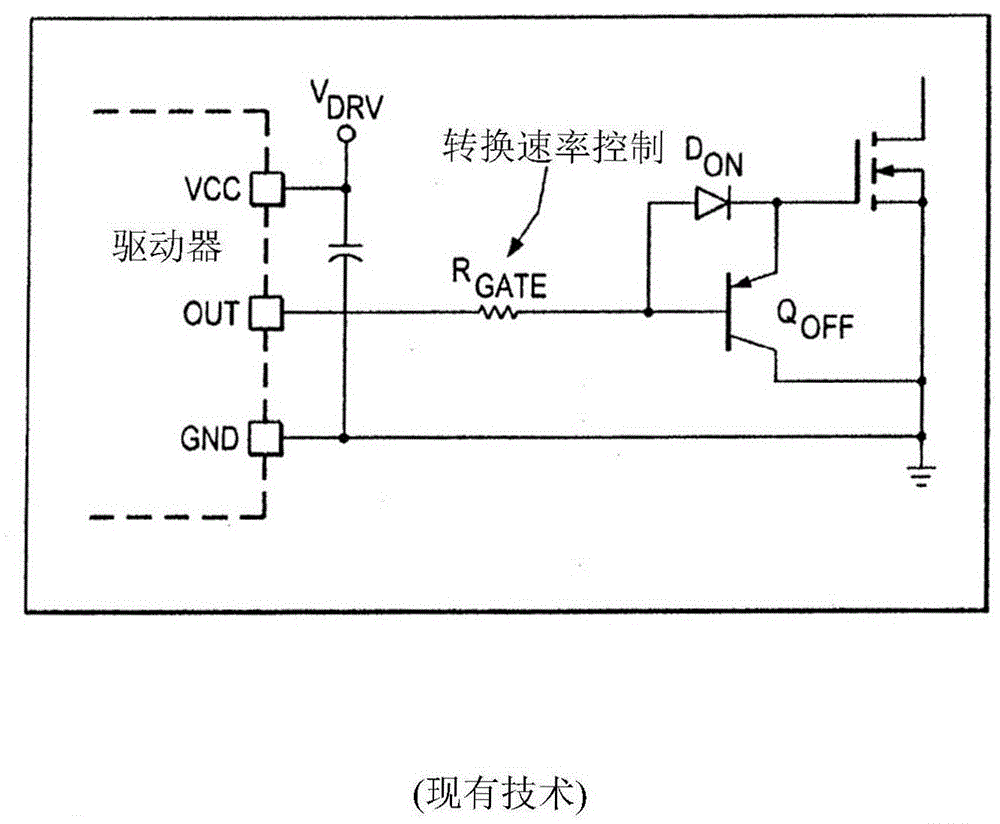

[0023] figure 1 Description Use a resistor R in series between the load driver circuit and the load switch GATE conventional slew rate control of the load driver circuit. Using a series resistor in this way moderates the voltage V across the load DS The rate of change, which reduces the amount of EMI and mitigates the kickback produced by rapid changes in the output voltage used to drive current loads. Using a series resistor to moderate the slew rate of the load switching does not provide sufficient control over the rate of change of the voltage across the load because the behavior of the resistor varies depending on the operating temperature of the system and because the resistor cannot account for the load switching rate. The margin variation in the switch (which can be significant when using transistor load switches such as MOSFETs) or the actual current drawn by the load. Furthermore, conventional resistor-based slew rate control is an open-loop solution that must be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com