Processing method for strong-flavor peanut milk

A processing method and technology of peanut milk, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems affecting the appearance and quality of products, and achieve the effect of strong smell, rich aroma and mellow taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

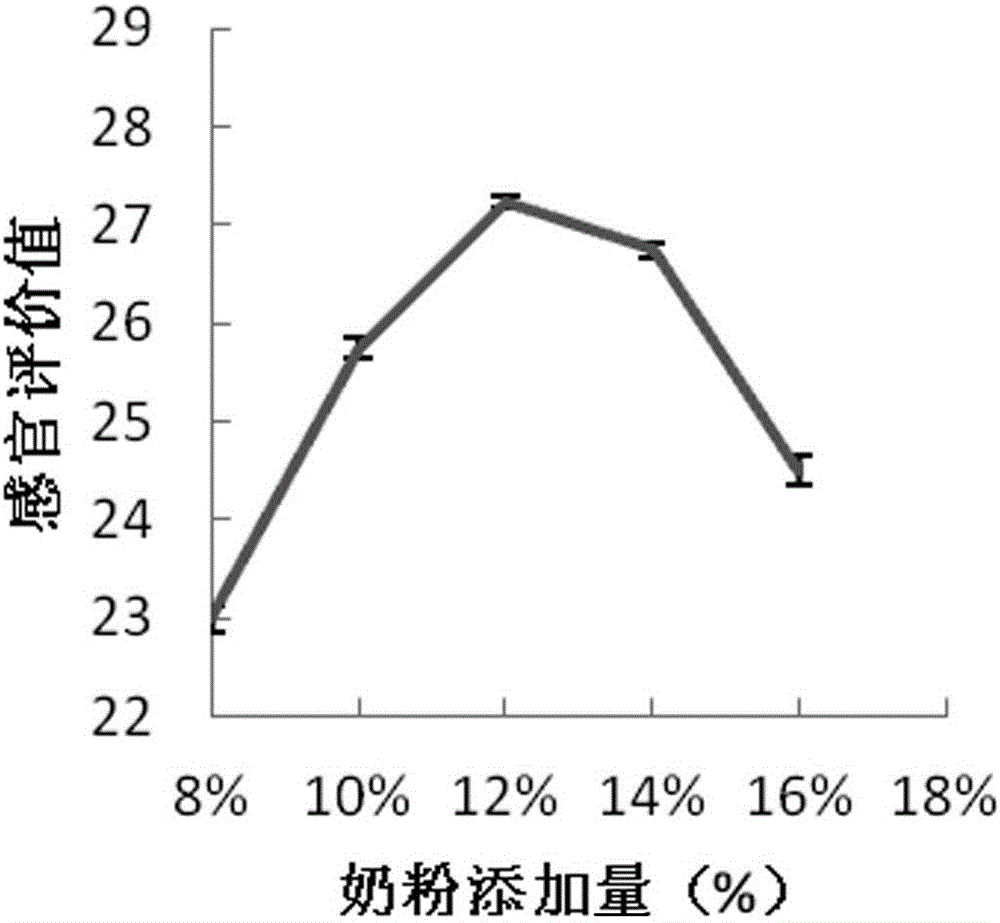

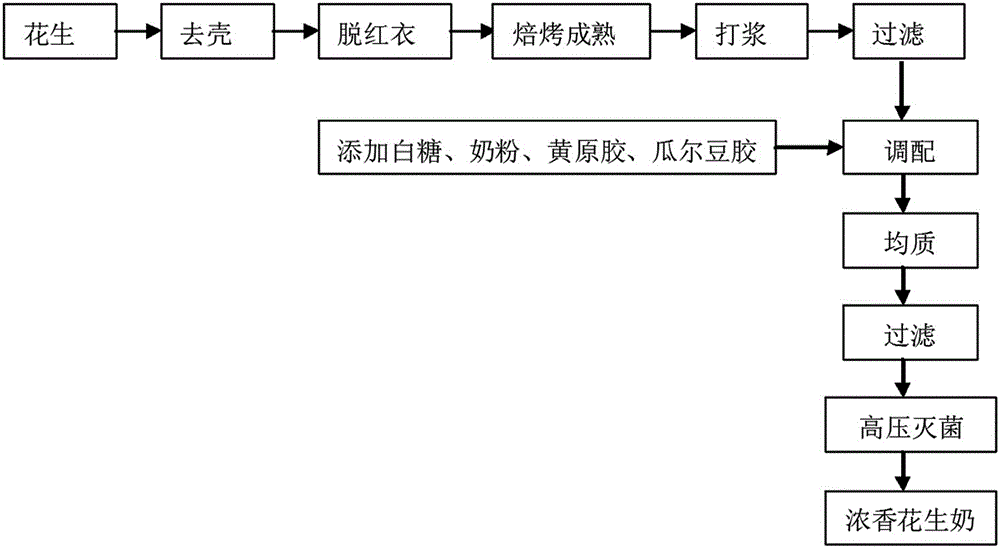

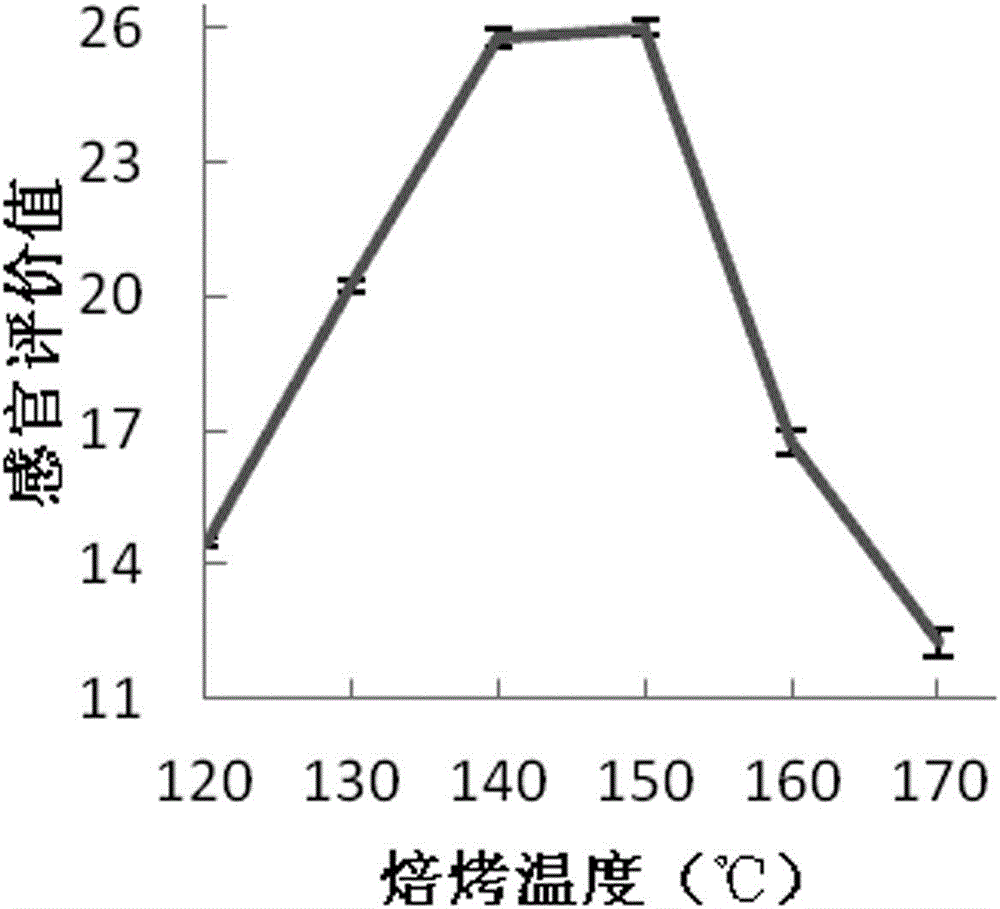

[0024] A method for processing rich-flavored peanut milk, the method comprising the following steps: (1) selecting ripe and full-bodied peanuts, roasting them in an oven to remove the red coat, continuing to bake the peeled peanuts in the oven until they are mature, Peanuts change from milky white to beige, and have a rich aroma of cooked peanuts. (2) Beat the roasted peanuts in a juicer, filter through 4 layers of white gauze, add milk powder, white sugar, and xanthan gum after filtering , guar gum for deployment, (3) then homogenize the prepared peanut milk under a homogenizer, then filter through 4 layers of gauze, and sterilize at high temperature to make a finished product. The above-mentioned milk powder addition accounts for 12.86% of the mass fraction of peanuts, the addition of white sugar accounts for 22.47% of the mass fraction of peanuts, the mass ratio of solid to liquid during beating is 1:14.96, the addition of stabilizers accounts for 0.58% of the mass fraction ...

Embodiment 2

[0026] The above-mentioned roasting temperature is 120°C, roasting time is 60 minutes, the mass ratio of solid to liquid during beating is 1:12, the amount of stabilizer added accounts for 0.30% of the mass fraction of peanuts, the amount of added milk powder accounts for 8% of the mass fraction of peanuts, and the amount of added sugar accounts for 12% of the mass fraction of peanuts. %, the mass ratio of xanthan gum to guar gum is 2:1. Other steps are the same as in Example 1.

Embodiment 3

[0028] The above-mentioned roasting temperature is 170°C, roasting time is 35 minutes, the mass ratio of solid to liquid during beating is 1:16, the amount of stabilizer added accounts for 0.70% of the mass fraction of peanuts, the amount of added milk powder accounts for 16% of the mass fraction of peanuts, and the amount of added sugar accounts for 24% of the mass fraction of peanuts. %, the mass ratio of xanthan gum to guar gum is 6:1. Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com