Flue-cured tobacco quality-improving fragment-increasing moisturizing agent under dry and low humidity environment and application method thereof

A wet environment, moisturizing agent technology, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problems of low moisture content, insufficient aroma, poor color of tobacco leaves, and achieve the effects of wide source of raw materials, improved tobacco leaf quality, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

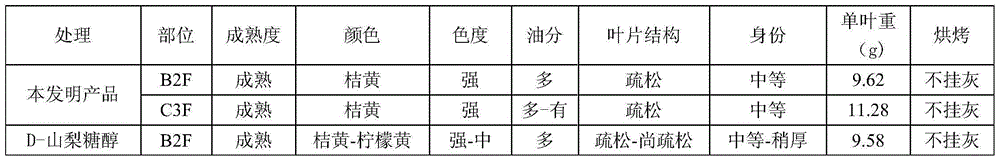

[0023] Take the product of the present invention (D-sorbitol and biochemical potassium fulvate are evenly mixed according to the ratio of mass ratio 1:4), and use the same weight of D-sorbitol alone as a comparison 1. Use biochemical potassium fulvate alone to make Control 2, and the same amount of clear water as control 3. In 2014, in the tobacco-growing area in southern Hunan, under the weather without rain for 8 consecutive days, after picking fresh tobacco leaves of K326, the same weight was taken and prepared with a concentration of 900 times. After the solution, spray evenly according to the usage amount of 18kg / room, and then weave the rods to load the smoke into the room. The amount of smoke installed is about 4000kg / room. They are all ignited and baked according to the existing intensive curing room and the existing baking process. After roasting, the appearance quality indicators of B2F and C3F tobacco leaves were better than those of various controls, and the curing ...

Embodiment 2

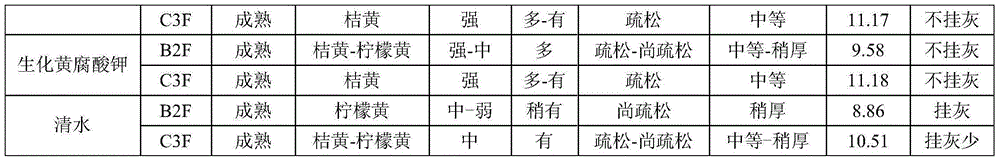

[0032] Take the product of the present invention (D-sorbitol and biochemical potassium fulvate are evenly mixed according to the ratio of mass ratio 1:4), and use the same weight of D-sorbitol alone as a comparison 1. Use biochemical potassium fulvate alone to make Control 2, and the same amount of water as control 3. In 2014, in the tobacco-growing area of central Hunan, under the weather without rain for 10 consecutive days, fresh tobacco leaves of Xiangyan No. 3 tobacco were picked, and the solution was prepared with 850 times the solution Finally, spray evenly according to the consumption amount of 17kg / room, and then weave rods to load tobacco into the room. The amount of smoke loaded is about 4000kg / room. After ignition and baking according to the existing curing room and baking process, the appearance of B2F tobacco leaves The quality indicators were all better than those of the unused control, and the curing property became better, and the single leaf weight increased...

Embodiment 3

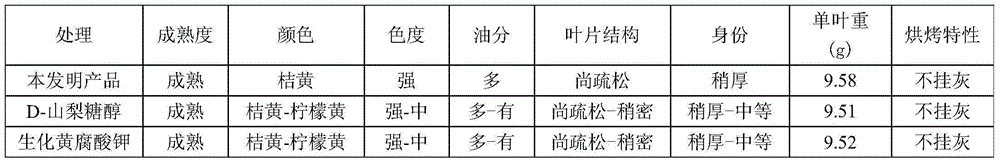

[0041]Take the product of the present invention (D-sorbitol and biochemical potassium fulvate are uniformly mixed according to the ratio of mass ratio 1:4), and use the same weight of D-sorbitol alone as a comparison 1. Use biochemical potassium fulvate alone to make Control 2, and the same amount of clear water as control 3. In 2014, in the Xiangxi area of Hunan Province, under the weather without rain for 12 consecutive days, fresh tobacco leaves of Yunyan 87 were picked and prepared into a solution by 850 times, and then 17kg / room Evenly spray the amount of tobacco used, and then weave the rods to load the tobacco into the room. The amount of tobacco installed is about 4100kg / room. After ignition and baking according to the existing curing room and curing process, the appearance quality indicators of B2F tobacco leaves are better than those of untreated tobacco. Compared with the control 1-3, the curing performance became better, and the single leaf weight increased by 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com