Preparation method and application of galangal wine

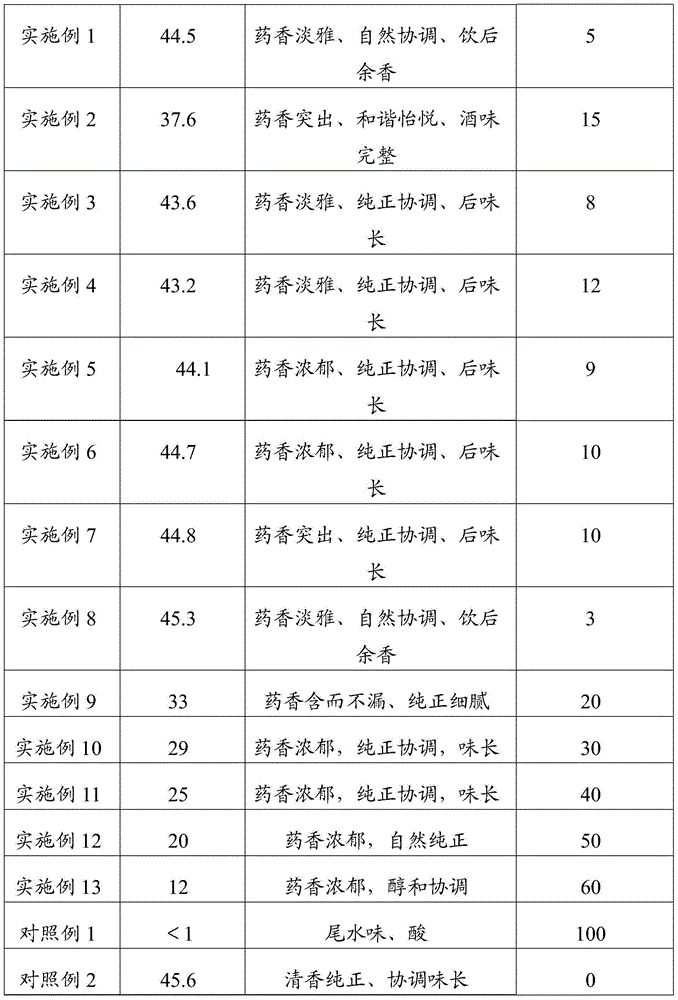

A technology of galangal wine and galangal is applied in the preparation of alcoholic beverages, medical preparations containing active ingredients, pharmaceutical formulations, etc., and can solve the problems of limited drug efficacy, difficulty in simultaneously guaranteeing alcohol yield and active ingredients, and the like, To achieve the effect of elegant and pleasant medicinal fragrance, satisfactory taste or quality, and harmonious wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The present embodiment provides a kind of preparation method of galanga wine, comprises the steps:

[0069] S1. Wash and crush galangal, then add 10 times the weight of galangal in water, decoct 3 times at 50°C for 1 hour each time, filter, combine extracts, and concentrate under reduced pressure to 60°C. The extract with a density of 1.15 is set aside;

[0070] Get 5 kg of remaining galangal residue in the above steps, get 95 kg of sorghum, mix well and pulverize or pulverize and mix well, then add 50 kg of water at 65° C. to moisten grits for 13 hours, and then steam the material for 60 minutes. The temperature of the material is controlled within 60-80°C to show a gradient change, and the first grain grains are obtained;

[0071] S2. Take the first grain grains described in step S1 out of the retort, then add 25kg of water at 10°C, add 14kg of Daqu and 0.4kg of dry yeast after cooling, control the temperature of entering the pond at 8°C, and carry out the fermentati...

Embodiment 2

[0074] The present embodiment provides a kind of preparation method of galanga wine, comprises the steps:

[0075] S1. Wash and crush the galangal, then add 15 times the weight of the galangal, decoct twice at 60°C for 3 hours each time, filter, combine the extracts, and concentrate under reduced pressure to 60°C. The extract with a density of 1.25 is set aside;

[0076] Get 15kg of remaining galangal residues in the above steps, take 85kg of sorghum, mix them and pulverize or pulverize them, then add 60kg of water at 55°C to moisten grits for 15 hours, and then steam the material for 40 minutes. The temperature of the material is controlled within 60-80°C to show a gradient change, and the first grain grains are obtained;

[0077] S2. Take the first grain grains described in step S1 out of the retort, then add 30kg of water at 5°C, add 11kg of Daqu and 0.5kg of dry yeast after cooling, control the temperature of entering the pond at 12°C, and carry out the fermentation of th...

Embodiment 3

[0080] The present embodiment provides a kind of preparation method of galanga wine, comprises the steps:

[0081] S1. Wash and crush the galangal, then add 12 times the weight of the galangal, decoct twice at 50°C for 2 hours each time, then filter, combine the extracts, and concentrate under reduced pressure to 60 The extract with a relative density of 1.20 at ℃, for later use;

[0082] Get 8 kg of remaining galangal residue in the above steps, take 92 kg of sorghum, mix well and pulverize or pulverize and mix well, then add 53 kg of water at 58° C. to moisten grits for 15 hours, and then carry out retort steaming for 45 minutes. The temperature of the steaming material is controlled within 60-80°C to show a gradient change, and the first grain grains are obtained;

[0083] S2. Take the first grain grains described in step S1 out of the retort, then add 28kg of water at 8°C, add 13kg of Daqu and 0.45kg of dry yeast after cooling, control the temperature of entering the pond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com