Method for conducting cold rolling on lead-acid storage battery grid gradually

A lead-acid battery, progressive technology, applied in the direction of metal rolling, etc., can solve the problems of battery electrochemical performance decline, poor grid corrosion resistance, etc., to increase the grain boundary volume fraction, improve electrical conductivity and corrosion resistance , Eliminate the effect of grid pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Four-stage cold rolling technology to process 60Ah automotive battery grid. The first stage is compressed to 95% of the original thickness, the second stage is compressed to 85% of the original thickness, the third stage is compressed to 75% of the original thickness, and the fourth stage is compressed to 60% of the original thickness. The results show that the cycle life of the battery prepared without cold-rolling can reach 250 times; the battery prepared after cold-rolling the grid can reach 350 times.

Embodiment 2

[0016] Three-stage cold rolling technology processing 5Ah motorcycle battery grid. The first stage is compressed to 95% of the original thickness, the second stage is compressed to 85% of the original thickness, and the third stage is compressed to 80% of the original thickness. The results show that the cycle life of the battery prepared without cold-rolling can reach 350 times; the battery prepared after cold-rolling the grid can reach 500 times.

Embodiment 3

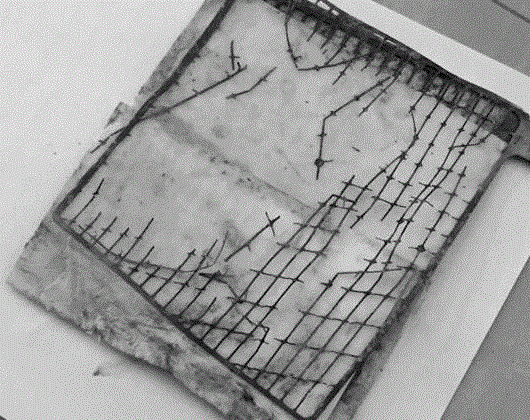

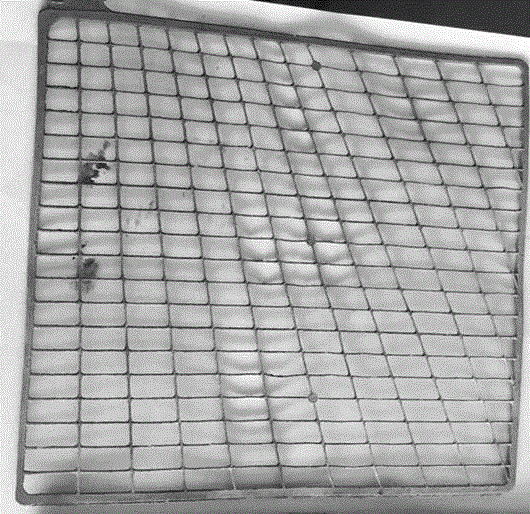

[0018] Three-stage alloy cold-rolled 69Ah start-stop battery grid and three-stage cold-rolled grid comparison test. The technology adopted by the former is three times cold-rolled lead-based alloy, and then expanded and deformed into a grid lead strip, and finally made into a grid with a thickness of 1.2mm; the technical points adopted by the latter are as follows, the first stage is compressed to 95% of the original thickness , the second stage is compressed to 85% of the original thickness, the third stage is compressed to 80% of the original thickness, and finally a grid with a thickness of 1.2mm is made. The results show that the 69Ah start-stop battery grid prepared by the three-stage alloy cold rolling method has a few bubbles, and there are different thicknesses at different positions; while the grid obtained by the three-stage cold rolling method has no bubbles and is very uniform, and the prepared battery , can achieve 50,000 times of start and stop, which is signific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com