High-performance sulfide solid electrolyte sheet as well as preparation method and application thereof

A technology of solid electrolyte and electrolyte sheet, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low density and low ionic conductivity, and achieve the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Sulfide solid state electrolyte powder was prepared as follows:

[0033] Step (1): under an inert atmosphere, place 1 g of lithium sulfide (purity > 99%) and phosphorus pentasulfide (purity > 98%) in an agate mortar and grind separately for 10 minutes in a molar ratio of 4:1, and then grind the two Mixing and grinding for 10min to mix to obtain raw material powder;

[0034] Step (2): under an inert atmosphere, transfer 1 g of the raw material powder obtained in step 1 into a 100 mL aluminum oxide ball milling jar, seal it and put it into a ball mill for two-way ball milling, first clockwise ball milling for 30 minutes, and let stand for 10 minutes , and then ball-milled counterclockwise for 30min, left standing for 10min, the ball-milling speed was 370r / min, the total ball-milling time was 20h, and the grinding balls were 5 aluminum oxide grinding balls with a diameter of 10 mm and 15 with a diameter of 5 mm to obtain the solid state of sulfide. Electrolyte ...

Embodiment 2

[0040] Embodiment 2: The preparation method of a high-performance sulfide solid-state electrolyte sheet of this embodiment is carried out according to the following steps:

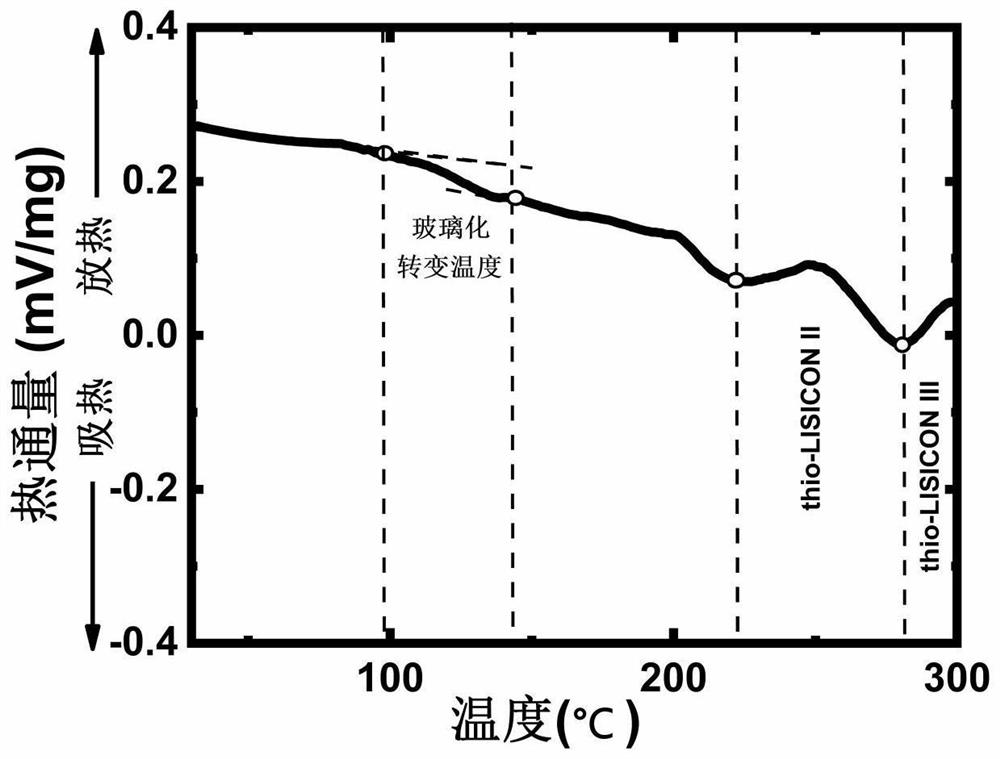

[0041] Step 1: After compacting the sulfide solid electrolyte powder of Example 1 to 801 μm, 804 μm, and 806 μm respectively, perform hot-pressing pretreatment at 280 °C, the heating rate is 20 °C / min, the holding time is 3h, and the heating is started for 1h After applying pressure, the pressure is 500 MPa, and the pressure holding time is 1 h. After the pressure is released, the heat preservation is continued, and after the heat preservation is completed, it is naturally cooled to room temperature to obtain an electrolyte sheet precursor; in this step, rapid cooling is adopted, thereby retaining the high phase transition temperature obtained. ionic phase;

[0042] Step 2: Heating the electrolyte sheet precursor to 130°C, the heating rate is 20°C / min, applying a pressure of 500MPa while heating and mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com