Vacuum sucker

A technology of vacuum suction cups and suction cups, which is applied in the field of mechanical equipment, can solve problems that affect production efficiency and machine utilization, large investment cannot be effectively returned, and fast and efficient clamping cannot be achieved, so as to improve processing efficiency and facilitate operation , adsorption and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

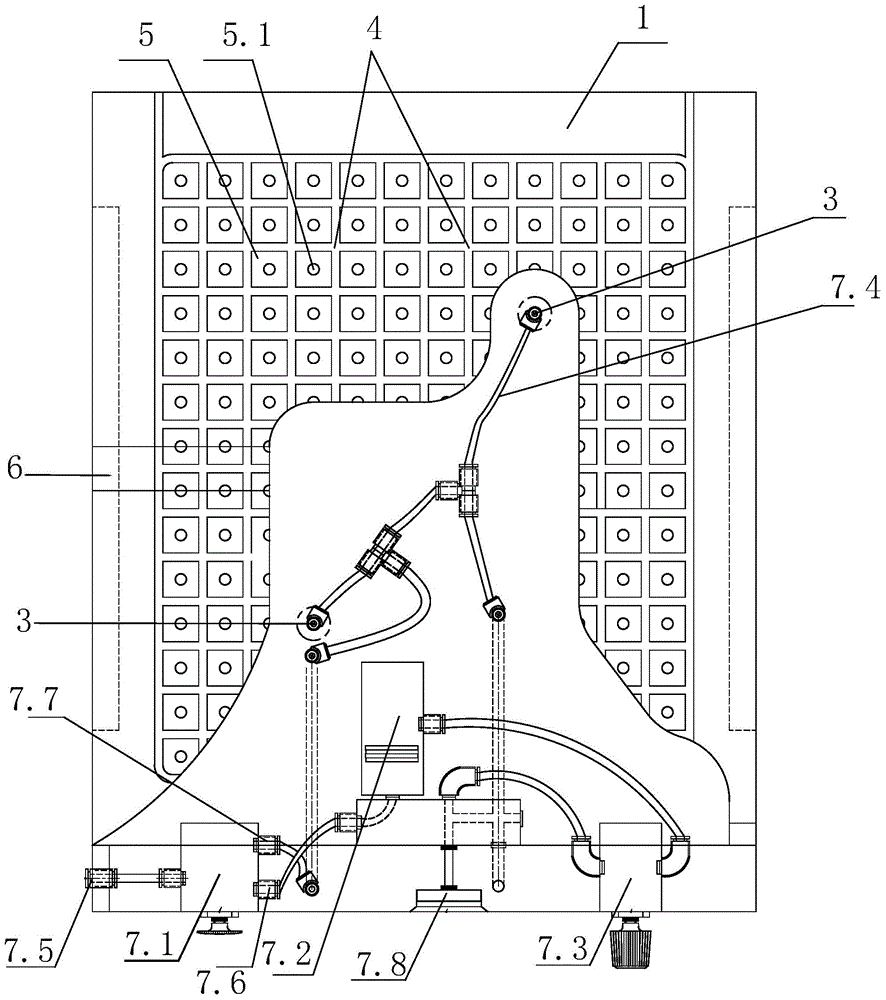

[0018] figure 1 The plan view of the present invention in , wherein the part separated by the curve is a schematic diagram of the back, which is a perspective drawing for easy understanding.

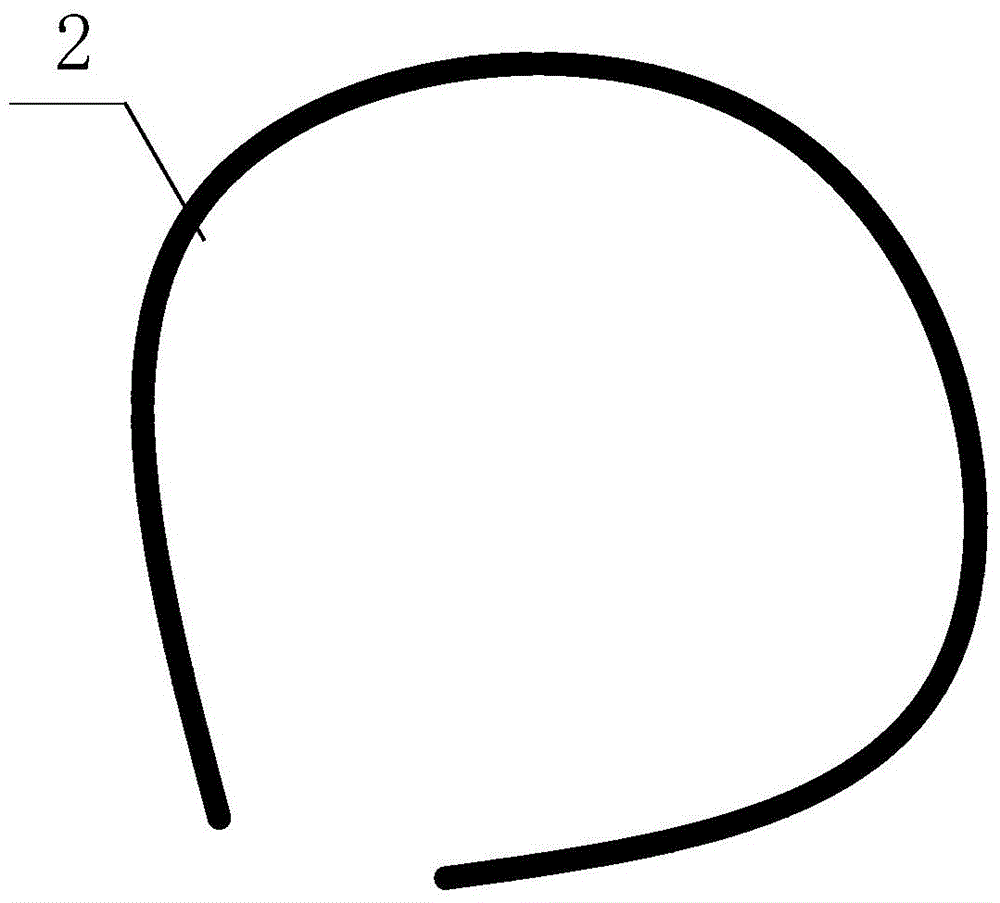

[0019] refer to figure 1 , figure 2 A vacuum suction cup is shown, including a suction cup body 1, an elastic seal 2 and a negative pressure forming component. A closed ring is formed between the front of the suction cup body 1 and the elastic seal 2, and the suction cup body 1 has several negative pressures in the closed ring. Hole 3, the negative pressure hole 3 communicates with the negative pressure forming component.

[0020] The front surface of the suction cup body 1 is arranged with a plurality of criss-cross grooves 4, and several closed groove rings can be formed between the grooves 4, and the elastic sealing member 2 is assembled in the closed groove rings.

[0021] The plurality of grooves 4 divide the front of the suction cup body 1 into a plurality of component blocks 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com