Grinding machine special for support roller of rolling mill

A technology for supporting rollers and special grinding machines, which is applied in the direction of grinding machines, grinding beds, and machine tools designed for grinding the rotating surface of workpieces. The effect of batch grinding and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and specific embodiments.

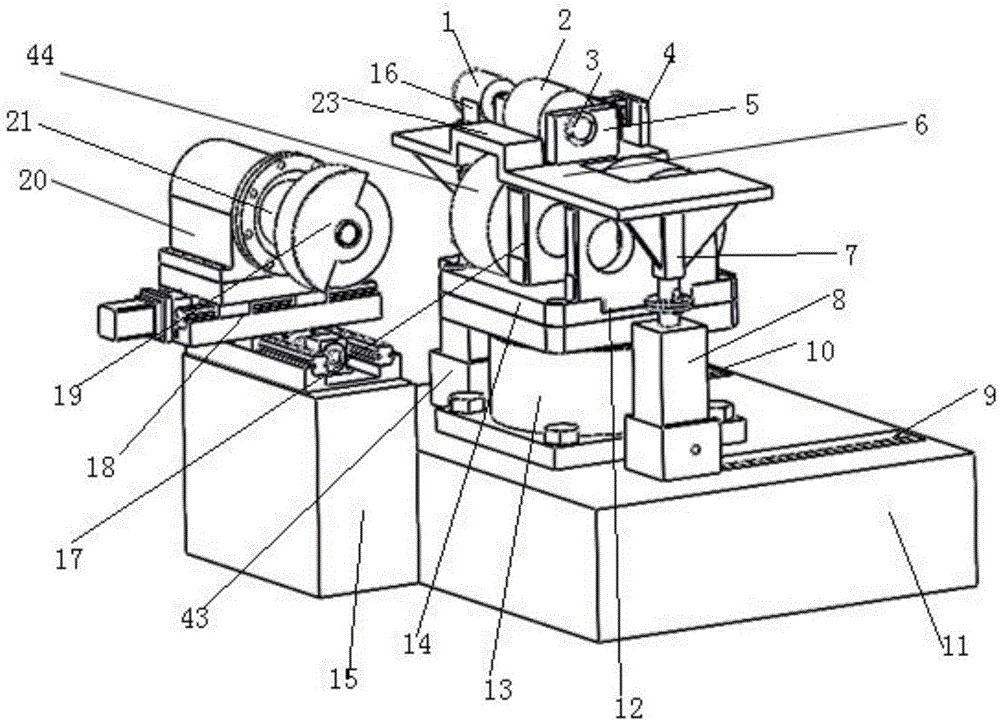

[0023] The present invention is a special grinding machine for supporting rollers of a rolling mill. figure 1 As shown, it includes a bed 11, one side of the bed 11 is provided with a boss 15, a cross slide 18 is installed on the boss 15, a grinding wheel mechanism is provided on the work table of the cross slide 18, and the center of the bed 11 A vertically arranged numerical control turntable 13 is installed. The table surface of the numerical control turntable 13 is equipped with an auxiliary turntable 14 for installing the workpiece to be processed. The workpiece to be processed installed on the auxiliary turntable 14 is level with the height of the grinding wheel mechanism. Rails A9 and B10 parallel to each other are respectively provided on the sides. Vertically arranged hydraulic cylinders A8 and B43 are respectively installed in the guide rails A9 and B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com