A process method based on coloring on the surface of 3D printed products

A 3D printing and processing method technology, applied in the field of 3D printing, can solve the problems of large manpower consumption, complicated operation process, difficulty in reducing costs, etc., and achieve the effect of saving manpower and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

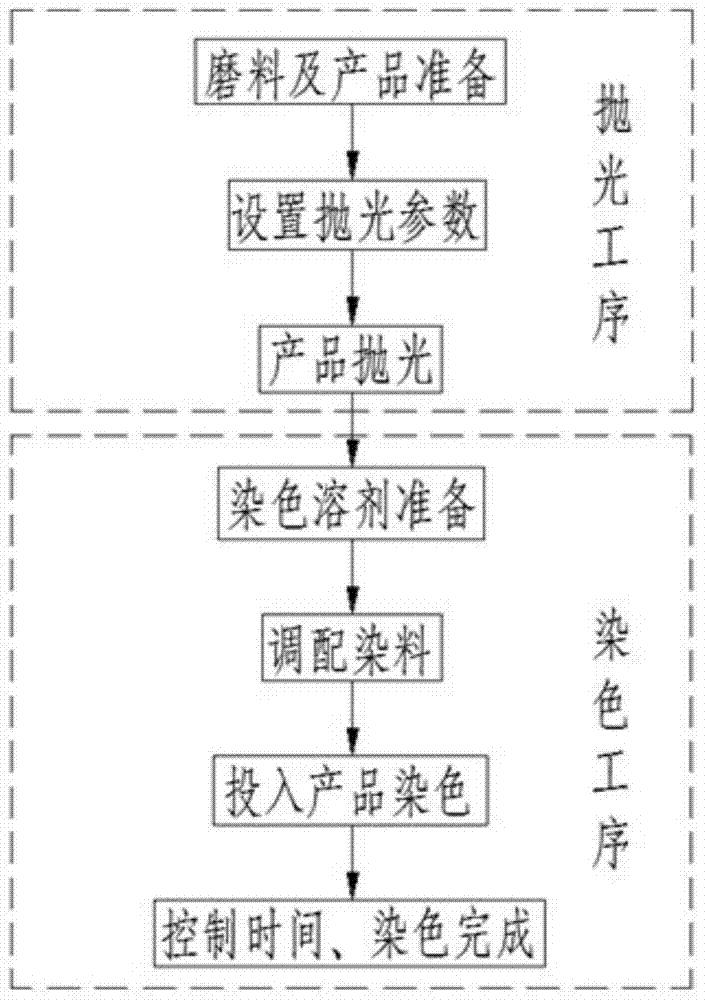

[0030] 1), surface polishing process, comprises the following steps:

[0031] a), adding abrasives and 3D printing products with a volume ratio of 1:1 in the polishing equipment, the total volume of abrasives and 3D printing products accounts for 96% of the total volume of the container of the polishing equipment, and the addition ratio accounts for the total volume of the container of the polishing equipment. 3% of the volume of water, the proportion of adding 1% of the total volume of the polishing equipment container polishing liquid, the order of addition is to add water, polishing liquid and abrasives and mix them evenly, and finally add the 3D printing product;

[0032] b), set the rotating speed of the polishing equipment drum to 30r / min;

[0033] c) Turn on the polishing equipment to complete the polishing of the 3D printed product; check the polishing situation every 30 minutes during the polishing process until the surface roughness of the 3D printed product reaches ...

Embodiment 2

[0040] 1), surface polishing process, comprises the following steps:

[0041] a), adding abrasives and 3D printing products with a volume ratio of 1:2 in the polishing equipment, the total volume of abrasives and 3D printing products accounts for 98% of the total volume of the container of the polishing equipment, and the addition ratio accounts for the total volume of the container of the polishing equipment. 4% of the volume of water, the proportion of adding 3% of the total volume of the polishing equipment container polishing liquid, adding order is to add water, polishing liquid and abrasives and mix evenly, and finally add the 3D printing product;

[0042] b), set the rotating speed of the polishing equipment drum to 1500r / min;

[0043] c) Turn on the polishing equipment to complete the polishing of the 3D printed product; check the polishing condition every 30 minutes during the polishing process until the surface roughness of the 3D printed product reaches Ra6. Take o...

Embodiment 3

[0050] 1), surface polishing process, comprises the following steps:

[0051] a), adding abrasives and 3D printing products with a volume ratio of 1:3 in the polishing equipment, the total volume of abrasives and 3D printing products accounts for 98% of the total volume of the container of the polishing equipment, and the addition ratio accounts for the total volume of the container of the polishing equipment. 5% of the volume of water, the proportion of adding 5% of the total volume of the polishing equipment container polishing liquid, the order of addition is to add water, polishing liquid and abrasives and mix evenly, and finally add the 3D printing product;

[0052] b), set the rotating speed of the polishing equipment drum to 1800r / min;

[0053] c) Turn on the polishing equipment to complete the polishing of the 3D printed product; check the polishing condition every 30 minutes during the polishing process until the surface roughness of the 3D printed product reaches Ra1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com