Method for 3D printing of thin-film solar cell

A solar cell and 3D printing technology, applied in the field of 3D printing thin-film solar cells, can solve the problems of inability to effectively control the printing quality, low photoelectric conversion efficiency of thin-film solar cells, etc., achieve controllable surface roughness, highlight substantive features, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

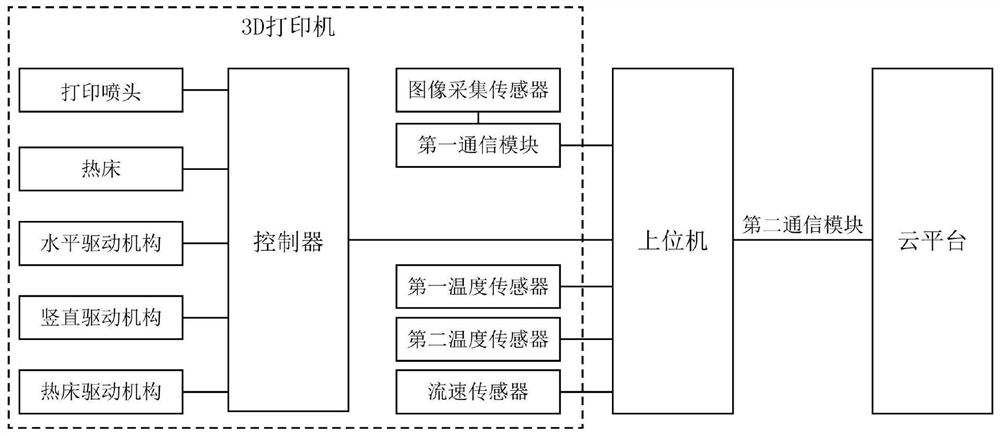

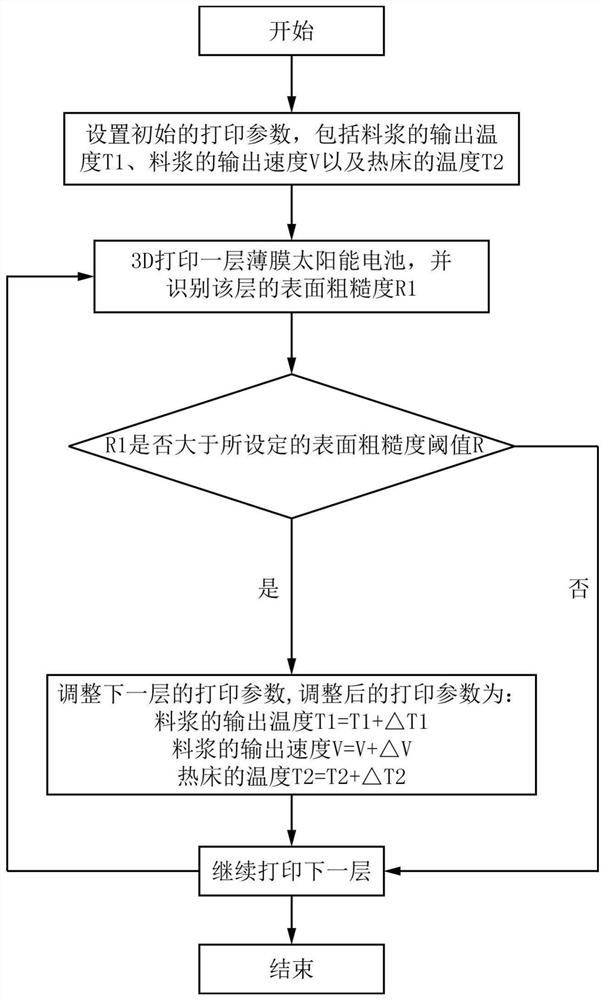

[0062] see Figure 1-Figure 2 , a method for 3D printing thin-film solar cells is provided in this embodiment, comprising the following steps: Step 1, constructing a 3D printing system for printing thin-film solar cells; wherein, the 3D printing system includes a 3D printer, a detection unit, Host computer and cloud platform, wherein, described 3D printer comprises hot bed 403, print nozzle 306, delivery pump, and delivery pump communicates with described printing nozzle 306 and the container that is used to store slurry through delivery pipeline 307 respectively, so that for The slurry is powered by the output of the printing nozzle 306; the slurry used for printing can be configured in advance in the container, so it will not be repeated here; the hot bed 403 can preferably use polyimide heating sheet or PCB heating Bed, in order to heat up to the set temperature, prevent the problem of edge warping in the printing process; the print nozzle 306 is used to output the configur...

Embodiment 2

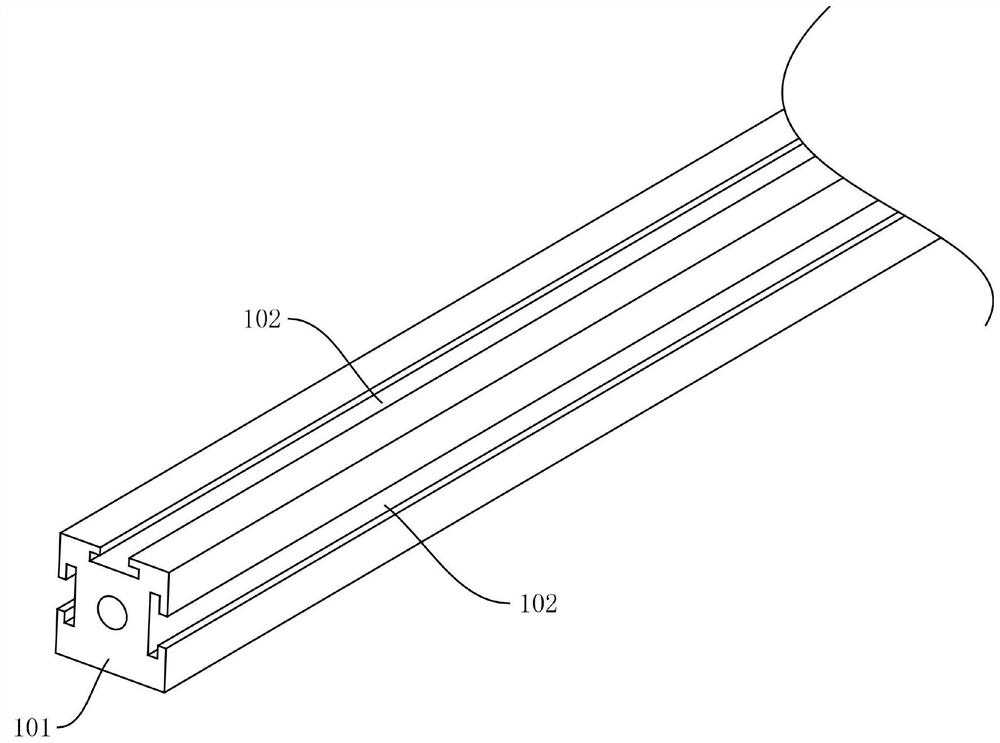

[0093] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that this embodiment provides a more compact 3D printing system, especially suitable for printing thin-film solar cells; specifically, as Figure 3-Figure 6 As shown, in this embodiment, the frame 100 can be a rectangular parallelepiped frame built from profiles 101, such as image 3 As shown, and the profiles 101 are respectively configured with installation grooves 102 distributed along the length direction and used for connecting bolts, so as to facilitate the installation, fixation and adjustment of various components.

[0094] In order to adjust the position of the print nozzle 306 along the Z direction, as a preference, in this embodiment, the vertical drive mechanism may include a first motor 203, a screw 204, a nut 205 adapted to the screw 204, Vertical slider 206 and guide bar 207, wherein,

[0095] Such as Figure 4-Figure 6As shown, the guide rod 207 is vertically fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com