Protective film pasting mechanism for door plate

A technology of protective film and door panels, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of low efficiency, high labor intensity, high cost, etc., achieve cost reduction, reduce labor intensity, simplify equipment structure and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

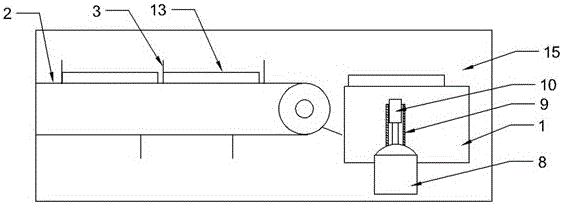

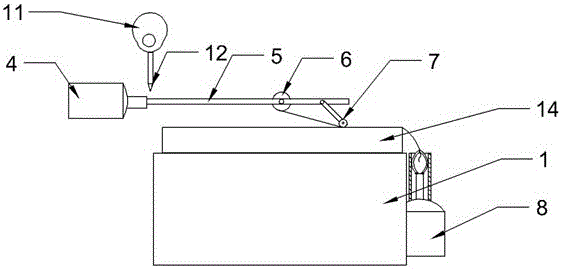

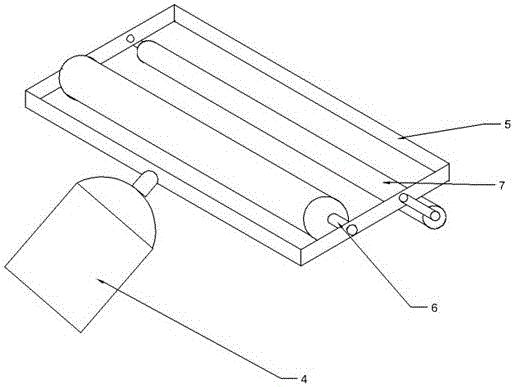

[0018] The reference signs in the drawings of the description include: processing table 1, conveyor belt 2, partition 3, hydraulic cylinder 4, support frame 5, support shaft 6, laminating roller 7, cylinder 8, sleeve 9, arc clamping Part 10, cam mechanism 11, cutting tool 12, door panel 13, protective film 14, frame 15.

[0019] The embodiment is basically as attached figure 1 Shown: a kind of sticking mechanism that is used for door panel protective film 14, comprises frame 15, processing table 1, transmission unit, pulling film unit, sticking film unit and cutting unit, and described transmission unit comprises conveyor belt 2, and described conveyor belt 2 is along from Partition boards 3 are fixedly installed at intervals from left to right, and the distance between two adjacent partition boards 3 matches the width of the door panel 13 , so that one door panel 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com