Light steel keel automatic packing system

A light steel keel, automatic technology, used in packaging, bundling materials, parts of bundling machinery, etc., can solve the problem of not meeting the production requirements of high-speed keel machines, and achieve the effect of stable packaging, avoiding easy damage and rapid packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

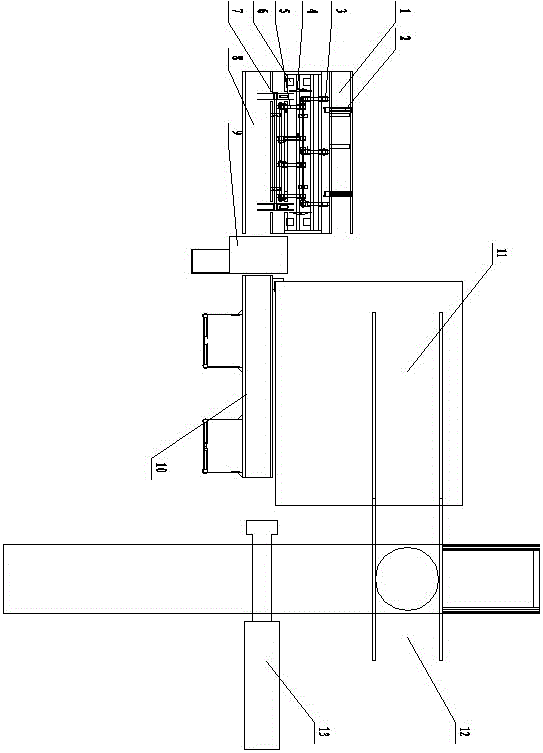

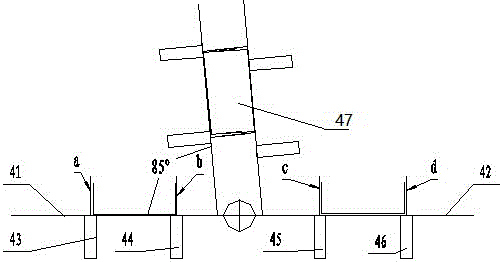

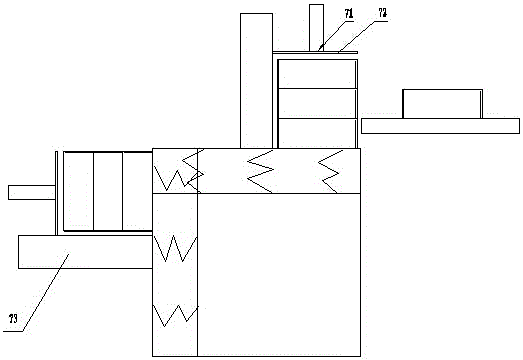

[0014] Such as figure 1 As shown, the light steel keel automatic packing system includes a non-powered roller line 1, a lifting and transplanting device 2, a conveyor belt 3, an internal turning mechanism 4, a conveyor belt 2 5, a "ten" code bundling mechanism 7, Conveying roller line 8, PP strapping machine 9, palletizer 10, rotating conveying roller 12, baler 13 and the automatic control device of the whole system, the said unpowered roller line 1 is connected to the end of the light steel keel production line, the said unpowered Power drum line 1, lifting and transplanting device 2, conveyor belt 1 3, internal overturning mechanism 4, conveyor belt 2 5, "ten" code bundling mechanism 7, conveyor drum line 8, PP strapping machine 9, palletizer 10. The rotary conveying drum 12 and the baler 13 are sequentially connected. The formed fixed-length keel on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com