Semitransparent high haze opal glass for LED and preparation method thereof

An opalescent glass and translucent technology, applied in the field of translucent opalescent glass for LED and its preparation, can solve the problems of overflow, dazzling blue light, etc., and achieve the effects of long material property, improved production efficiency, and not easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A translucent opalescent glass for LEDs, consisting of the following components by mass percentage: SiO 2 64%, Al 2 o 3 2%, B 2 o 3 10%, ZnO4%, CaO1%, MgO1%, K 2 O2%, Na 2 O8%, Li2O1%, Na2SiF64%, P 2 o 5 3%.

[0027] The preparation method of the above-mentioned translucent opal glass for LED is as follows: mix the components in proportion to make a glass batch, melt at 1500°C for 3 hours, pull down at 1080°C to make a translucent opal glass tube, and anneal at 500°C 180min, natural cooling, that is, translucent opalescent glass for LED.

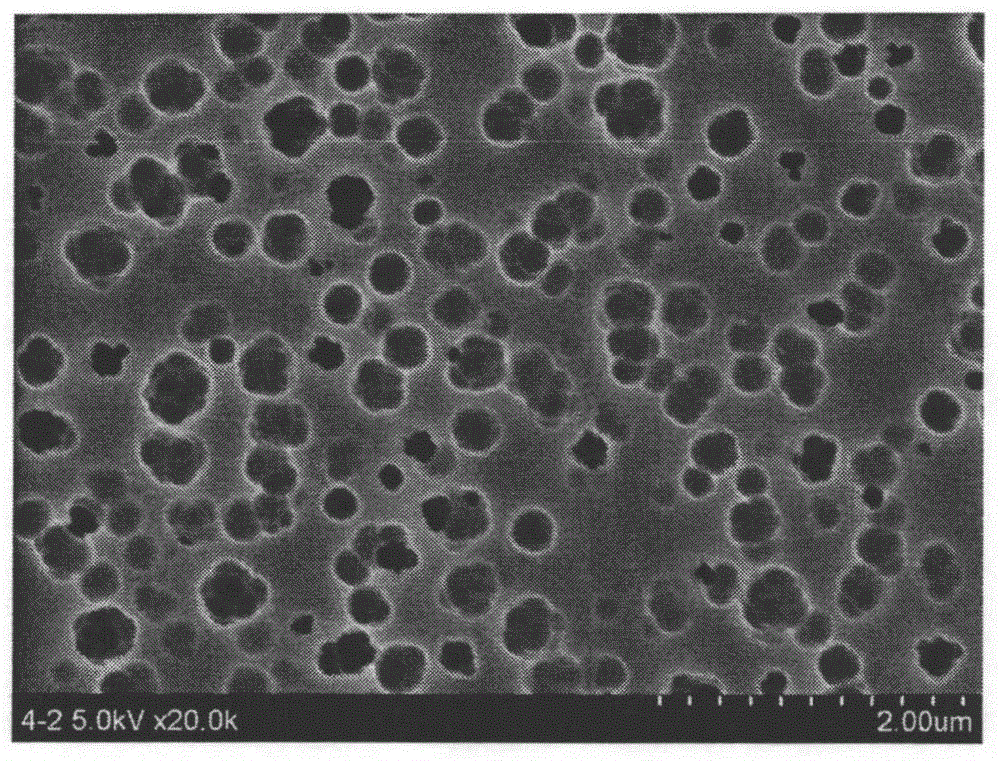

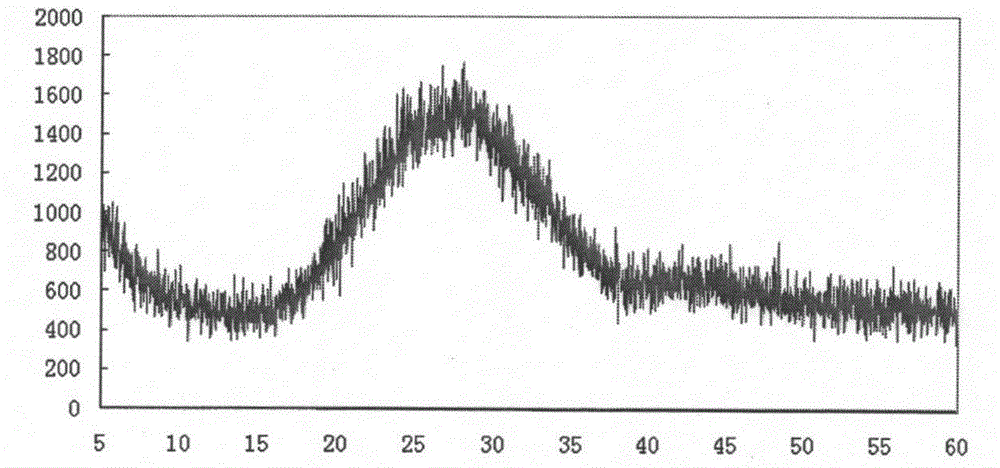

[0028] Such as figure 1 Shown is the SEM figure of the microscopic morphology of the translucent opalescent glass obtained in Example 1; figure 2 It is the XRD crystal phase spectrum of the translucent opalescent glass tube obtained in Example 1, which shows that it is phase-separated opalescent glass without devitrification. image 3 It is the photo of the translucent milky white glass tube obtained in Example 1.

[0029...

Embodiment 2

[0031] A translucent opalescent glass for LEDs, consisting of the following components by mass percentage: SiO 2 68%, Al 2 o 3 2%, B 2 o 3 8%, ZnO2%, CaO3%, MgO1%, alkali metal oxide K 2 O1%, Na 2 O7.5%, Li 2 O0.5, Na 2 SiF 6 3%, P 2 o 5 4%.

[0032] The preparation method of the above-mentioned translucent opalescent glass for LED is as follows: mix the components in proportion to make a glass batch, melt at 1550°C for 4 hours, pull down at 1100°C to make a translucent opalescent glass tube, and anneal at 550°C 120min, natural cooling, that is, translucent opalescent glass for LED.

[0033] The obtained translucent milky glass for LEDs has a thickness of 3 mm, a transmittance of 10%, a haze value of 30, and a whiteness of 60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com