Master batches, resin composition, diffusion plate and preparation method of diffusion plate

A technology of resin composition and masterbatch, which is applied in the field of resin products, can solve problems such as the decrease of transmittance, and achieve the effects of good haze, high shielding and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

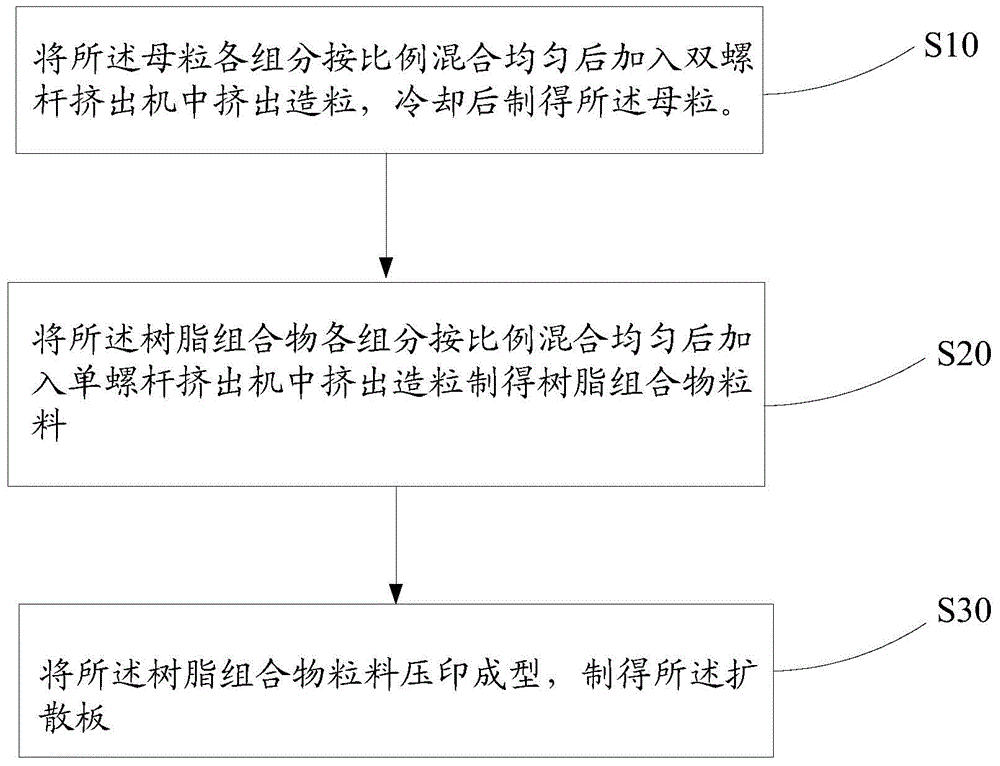

[0056] see figure 1 , the present invention also provides the preparation method of the above-mentioned diffusion plate, comprising:

[0057] S10: mix the components of the masterbatch evenly in proportion, then put them into a twin-screw extruder to extrude and granulate, and prepare the masterbatch after cooling.

[0058] By extruding and granulating with a twin-screw extruder, the components of the masterbatch can be uniformly mixed, and the prepared masterbatch is easier to take out and store. In this step, the twin-screw extruder is a twin-screw extruder with seven temperature zones, and the temperature of each zone and the temperature of the die head are respectively: the temperature of the first zone is 173-178°C; the temperature of the second zone is 183-188°C; The temperature of the zone is 195-200°C; the temperature of the fourth zone is 210-220°C; the temperature of the fifth zone is 225-230°C; the temperature of the sixth zone is 215-220°C; the temperature of the ...

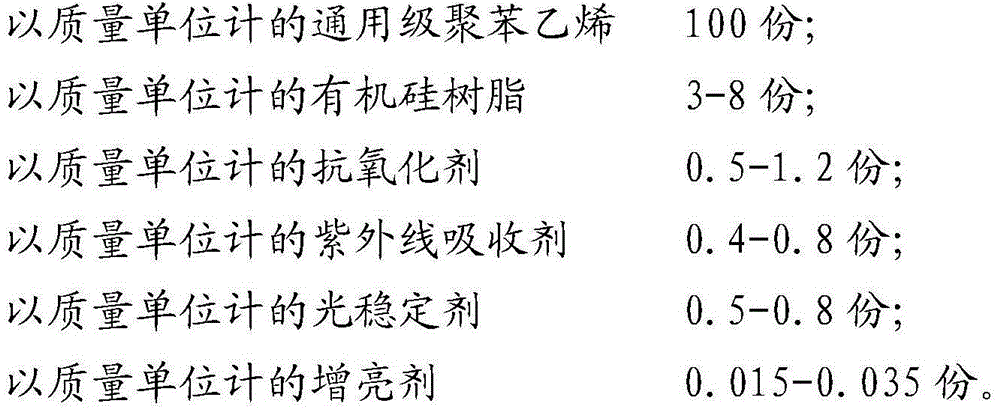

Embodiment 1

[0065] After mixing 100Kg general-purpose polystyrene, 5Kg silicone resin, 1.1Kg antioxidant, 0.6Kg ultraviolet absorber, 0.6Kg light stabilizer, 0.025Kg mineral oil, and 0.03Kg brightener, they are mixed in a twin-screw extruder The masterbatch obtained after middle extrusion granulation and natural cooling for 3.5-3.5 hours. The temperature of the first zone of the twin-screw extruder is 175°C, the temperature of the second zone is 185°C, the temperature of the third zone is 195°C, the temperature of the fourth zone is 215°C, the temperature of the fifth zone is 230°C, the temperature of the sixth zone is 220°C, and the temperature of the seventh zone is 220°C. The zone temperature is 215°C, the die head temperature is 210°C; the production rate is 220Kg / h.

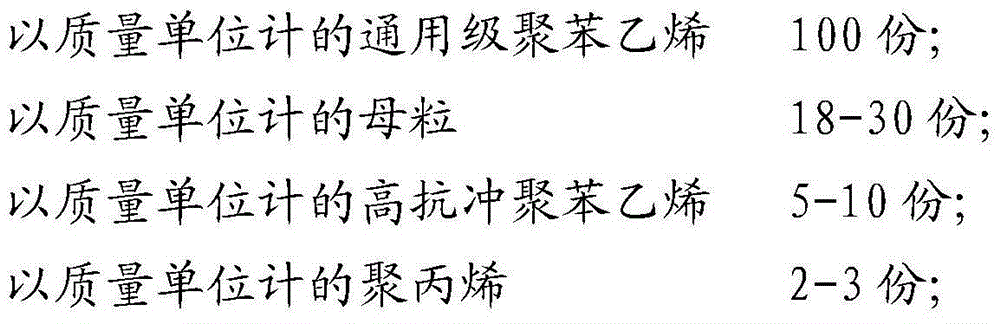

[0066] Mix 100Kg general-purpose polystyrene, 25Kg masterbatch, 8Kg high-impact polystyrene, 2.6Kg polypropylene, and 0.025Kg mineral oil evenly, extrude and granulate in a single-screw extruder to obtain resin composit...

Embodiment 2

[0068] After mixing 100Kg general-purpose polystyrene, 5Kg silicone resin, 1.1Kg antioxidant, 0.6Kg ultraviolet absorber, 0.6Kg light stabilizer, 0.025Kg mineral oil, and 0.03Kg brightener, they are mixed in a twin-screw extruder The masterbatch obtained after middle extrusion granulation and natural cooling for 3.5-3.5 hours. The temperature of the first zone of the twin-screw extruder is 175°C, the temperature of the second zone is 185°C, the temperature of the third zone is 195°C, the temperature of the fourth zone is 215°C, the temperature of the fifth zone is 230°C, the temperature of the sixth zone is 220°C, and the temperature of the seventh zone is 220°C. The zone temperature is 215°C, the die head temperature is 210°C; the production rate is 220Kg / h.

[0069] Mix 100Kg general-purpose polystyrene, 25Kg masterbatch, 6Kg high-impact polystyrene, 3.2Kg polypropylene, and 0.025Kg mineral oil evenly, extrude and granulate in a single-screw extruder to obtain resin composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com